Water-soluble coating composition for surface protection of nuclear fuel rod

A technology for nuclear fuel rods and coating agents, which is applied in the fields of reactor fuel elements, coatings, nuclear engineering, etc., can solve the problems of lack of alternative substances, unavoidable environmental pollution, fragility, etc., and achieves easy removal, improved working environment and operation. The effect of improving safety and operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1. Preparation of water-soluble coating agent composition

[0046] Next, a method for preparing a water-soluble coating composition for coating the surface of a nuclear fuel rod will be described.

[0047] As a polymer resin, the weight ratio of methacrylic acid (MAA) is 5.4%, the weight ratio of 2-hydroxyethyl methacrylate (2-HEMA) is 2.7%, and the weight ratio of methyl methacrylate (MMA) The ratio is 0.9%, and the weight ratio of the whole polymer resin obtained after adding them is 9.0%, and the weight ratio of the polymer resin dissolved in isopropyl alcohol (IPA) is 28.0%, and the weight ratio of ethanol (EtOH) is 50.0%. %, and a solvent in which the weight ratio of water is 13.1%, thereby preparing a coating agent composition. This coating agent composition is called YS-3 coating agent composition. Coating agent compositions similar to the YS-3 coating agent composition were prepared and tested. The polymer resin and solvent compositions of each coat...

Embodiment 2

[0051] Example 2. Evaluation of Physical Properties of Coated Films of Water-Soluble Coating Agent Compositions

[0052] A water-soluble coating agent was used to form a coating film on a flat test piece made of the same material as the fuel rod, and after drying, the pencil hardness was measured using a pencil hardness tester. The thickness of the applied coating film was measured using a light reflection type coating film thickness meter. The thickness of the coating film is measured with a coating film thickness meter, and the coating film to be measured is placed under a light source, and the thickness in μm is measured by measuring the amount of light reflected by irradiation with near-infrared rays.

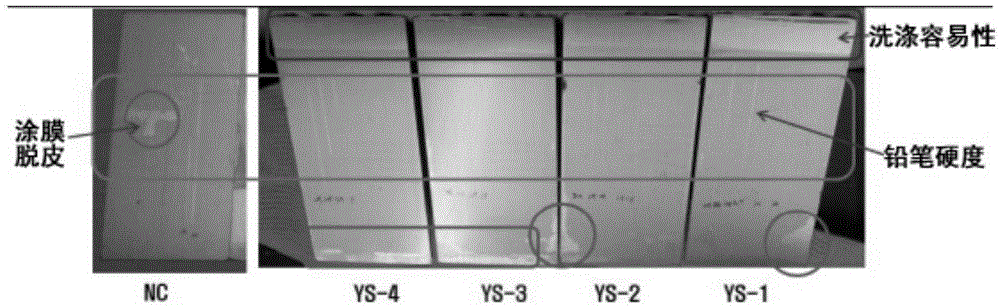

[0053] The adhesive strength evaluation test method was implemented as follows. After coating the coating agent on a flat plate with a size of 10×10 cm according to the type, cut off the coating film with a knife, remove it with an adhesive tape, and compare and evaluate b...

Embodiment 3

[0060] Example 3. Evaluation of Coating Agent Composition Using Fuel Rod Loading Test Device

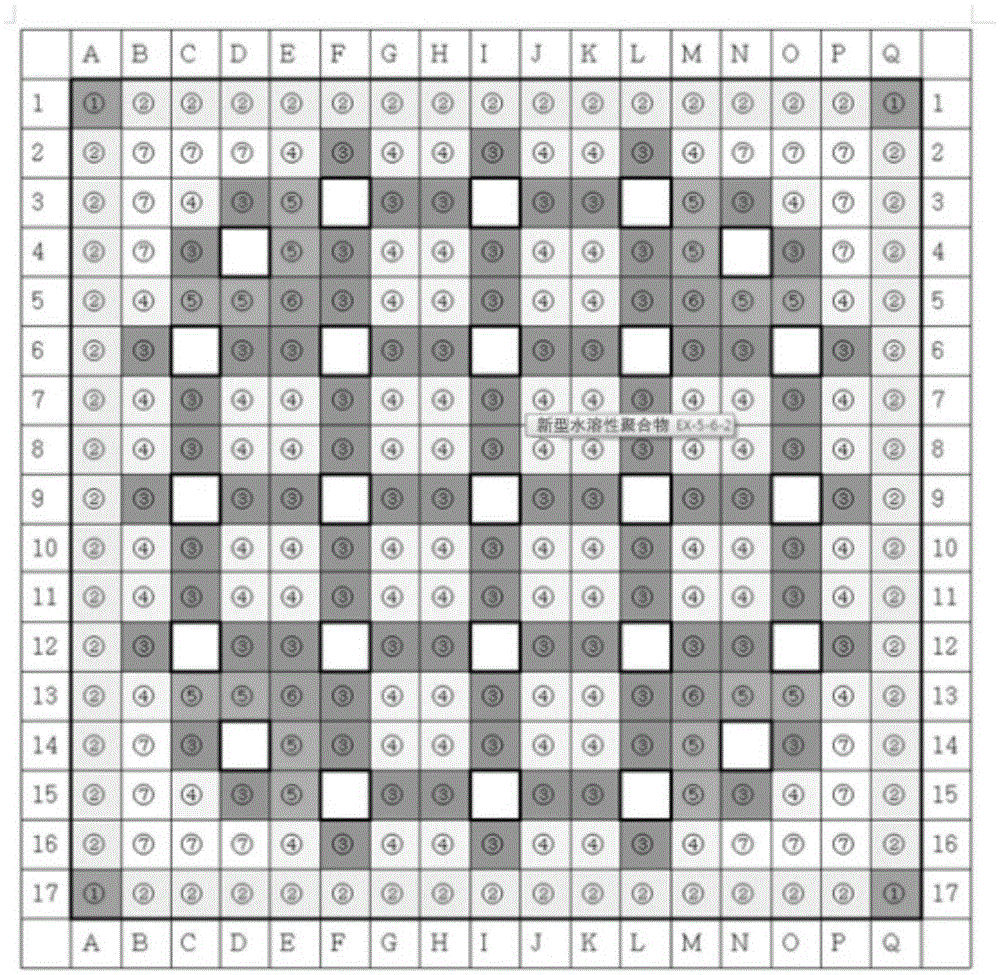

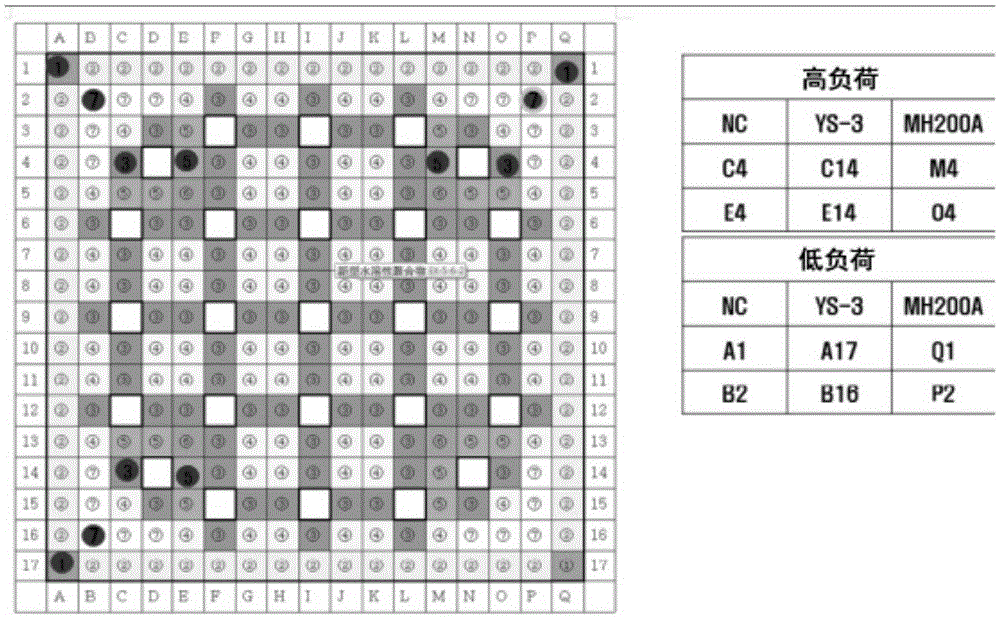

[0061] In order to apply the water-soluble coating agent to actual fuel rods, a small-scale fuel rod loading test device was fabricated to measure the load at the time of loading and the depth and width of the scratches on the fuel rods, thereby evaluating the water-soluble coating agent and the fuel rod. Comparative evaluation of existing paint (NC) coating agents.

[0062] The device for the fuel rod loading test was prepared in the following configuration. The frame with a size of about 4 m actually used for loading fuel rods was reduced to 1.5 m, so that the manufactured fuel rod loading test device had three spacer grids (SpacerGrid) that could be loaded with fuel rods. , vertical, each 17, a total of 289 grid cells (GridCell) can be loaded into the structure of 264 fuel rods except the guide thimble tube (GuideThimbleTube, 24) and instrumentation tube (InstrumentationTube, 1)....

PUM

| Property | Measurement | Unit |

|---|---|---|

| ignition point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com