Graphene-doped anti-radiation coating and preparation method thereof

A technology of anti-radiation coating and graphene, which is applied in the field of graphene-doped anti-radiation coating and its preparation, and can solve the problems of lack of anti-radiation effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

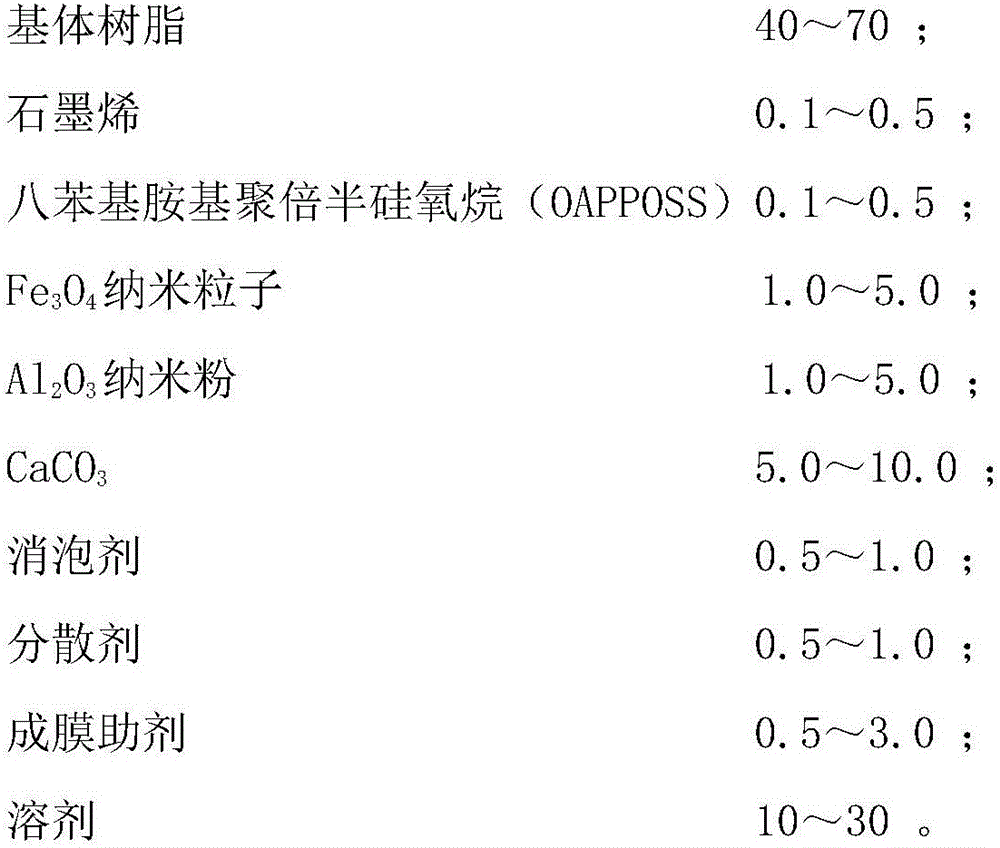

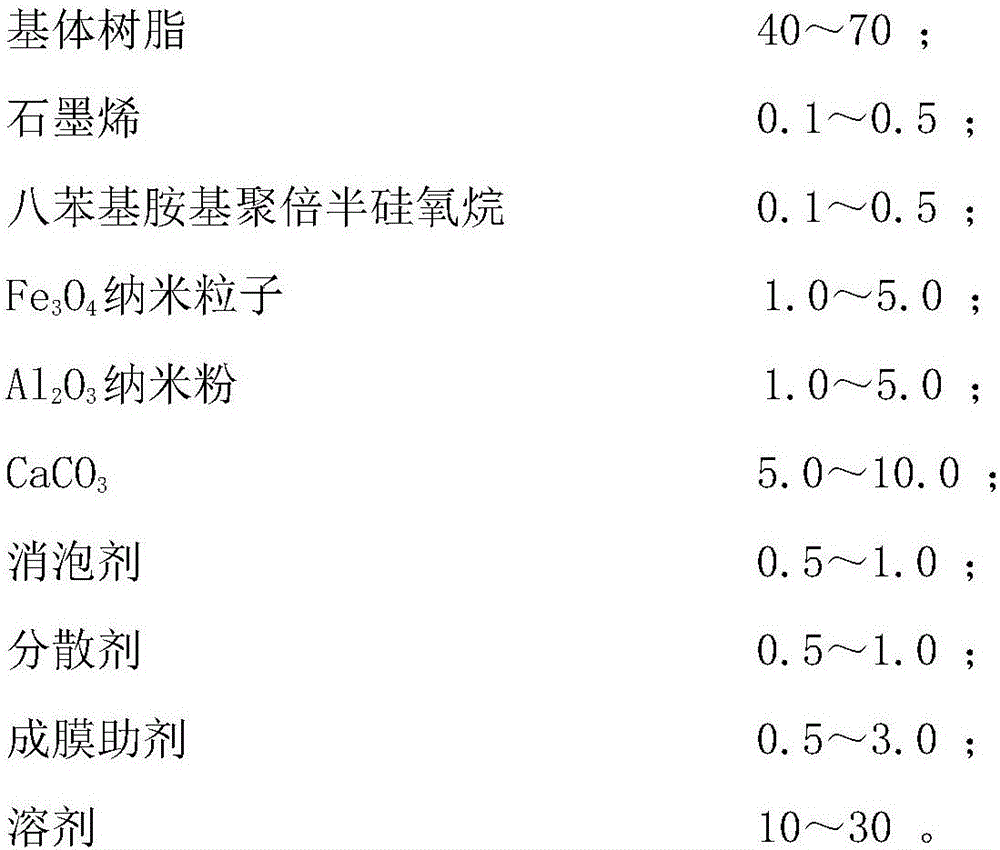

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the OAPPOSS refers to the literature M.Laine, etal.Octa(aminophenyl)silsesquioxaneasaNanoconstructionSite.J.Am.Chem.Soc.2001,123,12416-12417. The steps are as follows:

[0038] (1) Disperse 8 g of octaphenylpolysilsesquioxane (OPS) in 30-60 mL of nitric acid solution in an ice-water bath, and stir evenly for 30 min.

[0039] (2) Continue to react the OPS nitric acid solution at room temperature for 20 h, filter with suction and wash with water for 5 times to obtain a yellow precipitate.

[0040] (3) Place 8 g of the yellow precipitate obtained in (2) and 1 g of palladium-carbon catalyst in a round-bottomed flask, add 15 mL of tetrahydrofuran (THF) and 15 mL of triethylamine (TEA) under the protection of argon, and heat the reaction solution to 60 ° C. Add 8mL of formic acid and continue the reaction for 10h.

[0041] (4) After the reaction, the mixture was filtered with suction and washed five times with ethyl acetate and water respectively to...

Embodiment 1

[0043] Get graphene 0.1 weight part, OAPPOSS0.1 weight part by radiation-proof coating composition distribution ratio, Fe 3 o 4 2.0 parts by weight of nanoparticles, Al 2 o 3 Nano powder 2.0 parts by weight, CaO 35.0 parts by weight were mixed uniformly by a mixer at a speed of 700 r / min at room temperature, and then 10 parts by weight of solvent was added and stirred uniformly to form component A. Next, add 0.5 parts by weight of defoamer, 0.5 parts by weight of dispersant, and 1.0 parts by weight of film-forming aids to 40 parts by weight of matrix resin at a time, and stir and mix them uniformly at a speed of 800 r / min with a mixer at room temperature to form B components. Finally, mix A and B components evenly under the high-speed mixer at 1500r / min, ready for painting.

Embodiment 2

[0045] Get 0.3 parts by weight of graphene, OAPPOSS0.2 parts by weight, Fe 3 o 4 3.0 parts by weight of nanoparticles, Al 2 o 3 Nano powder 2.0 parts by weight, CaO 3 7.0 parts by weight were mixed uniformly by a mixer at a speed of 800 r / min at room temperature, and then 15 parts by weight of solvent was added and stirred uniformly to form component A. Next, add 0.8 parts by weight of defoamer, 0.7 parts by weight of dispersant, and 1.5 parts by weight of film-forming aids into 50 parts by weight of matrix resin at a time, and stir and mix them uniformly at a speed of 800 r / min with a mixer at room temperature to form B components. Finally, mix A and B components evenly under the high-speed mixer at 2000r / min, ready for painting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com