Formula and preparation method of peelable photocuring glass coating

A glass coating and light-curing technology, applied in epoxy resin coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of easy damage to processing tool heads, lack of energy saving and environmental protection, and very high requirements. Mechanical processing, good protection, good peeling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

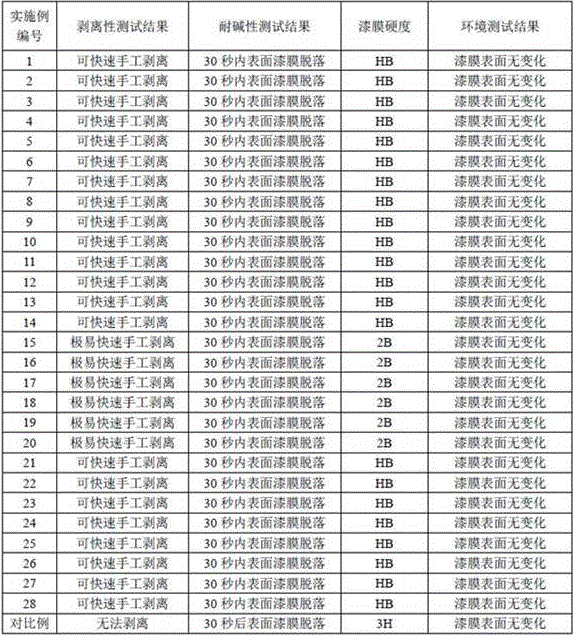

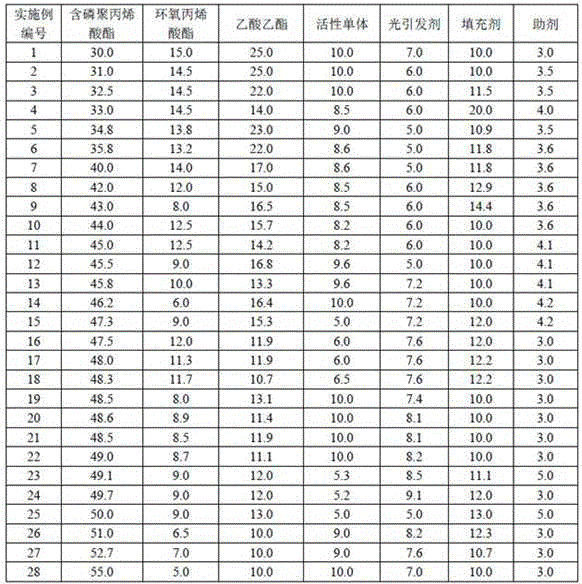

[0036] The content of the present invention is further described below by way of examples.

[0037] 1. Preparation of phosphorus-containing polyurethane acrylate

[0038] (1) The first step: Synthesis of polyurethane acrylic acid

[0039] Using a protective atmosphere of nitrogen, mix polypropylene glycol and isophorone diisocyanate at a molar ratio of 1:2.15, stir evenly and then heat up to 55°C, add dibutyltin dilaurate and hydroquinone at a mass ratio of 1:0.5 The mixture is used as a catalyst, and the amount of catalyst is small, just drop 15-20 drops with a dropper, then raise the temperature to 80°C, and react for 5 hours, until the content of isocyanate groups in the reaction system is reduced by 60%, add additional For hydroxyethyl acrylate with the same quality as polypropylene glycol, keep warm and continue to react for 2.5 hours.

[0040] (2) The second step: Synthesis of phosphorus-containing polyurethane acrylate

[0041] Under the protective atmosphere of nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com