Model-free boiler combustion optical control method based on numerical optimization extremum searching

A boiler combustion and numerical optimization technology, applied in the field of energy systems, can solve problems such as difficult to achieve expected results, failure to take into account boiler economy and emissions, high temperature corrosion of water wall in the burner area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

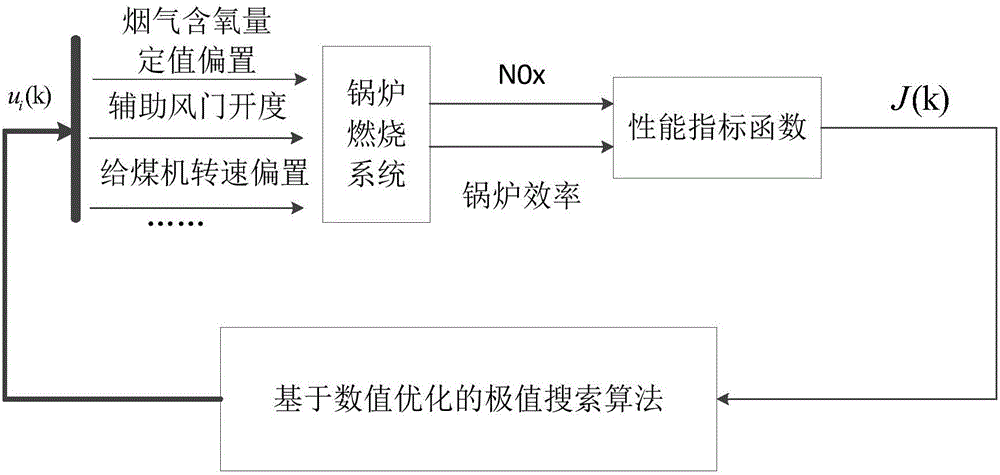

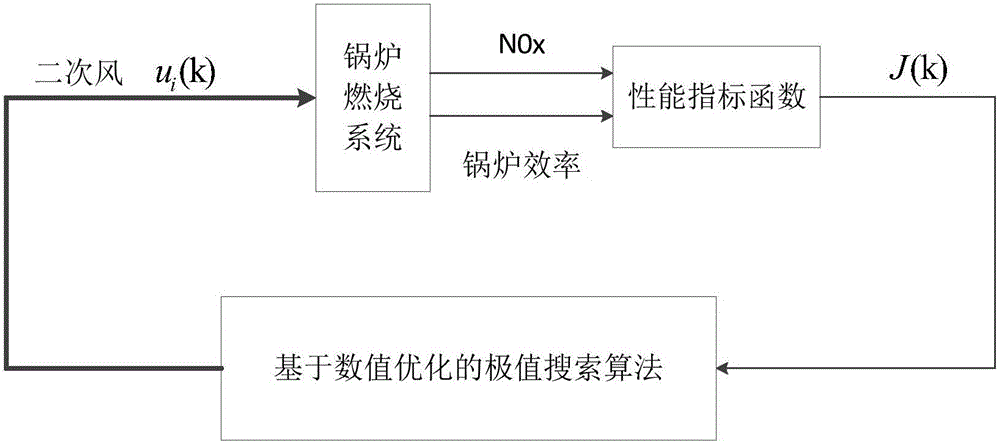

[0041] A model-free boiler combustion optimization control method based on numerical optimization extreme value search algorithm is used to solve the combustion optimization problem of a certain type of power plant boiler. For the sake of illustration, only the optimization of three layers of secondary air is considered. This case can be easily generalized to consider more optimization variables. Specific steps are as follows:

[0042] 1. Calculate performance indicators

[0043] The essence of combustion optimization is to improve boiler thermal efficiency on the basis of reducing NOx emissions, which is a multi-objective optimization problem. Here, the weighting factor is used to transform the multi-objective optimization problem into a single-objective problem, and then through different combinations of weights, different optimization solutions are obtained to provide support for optimization decisions. The mathematical description of the optimization problem including t...

Embodiment 1

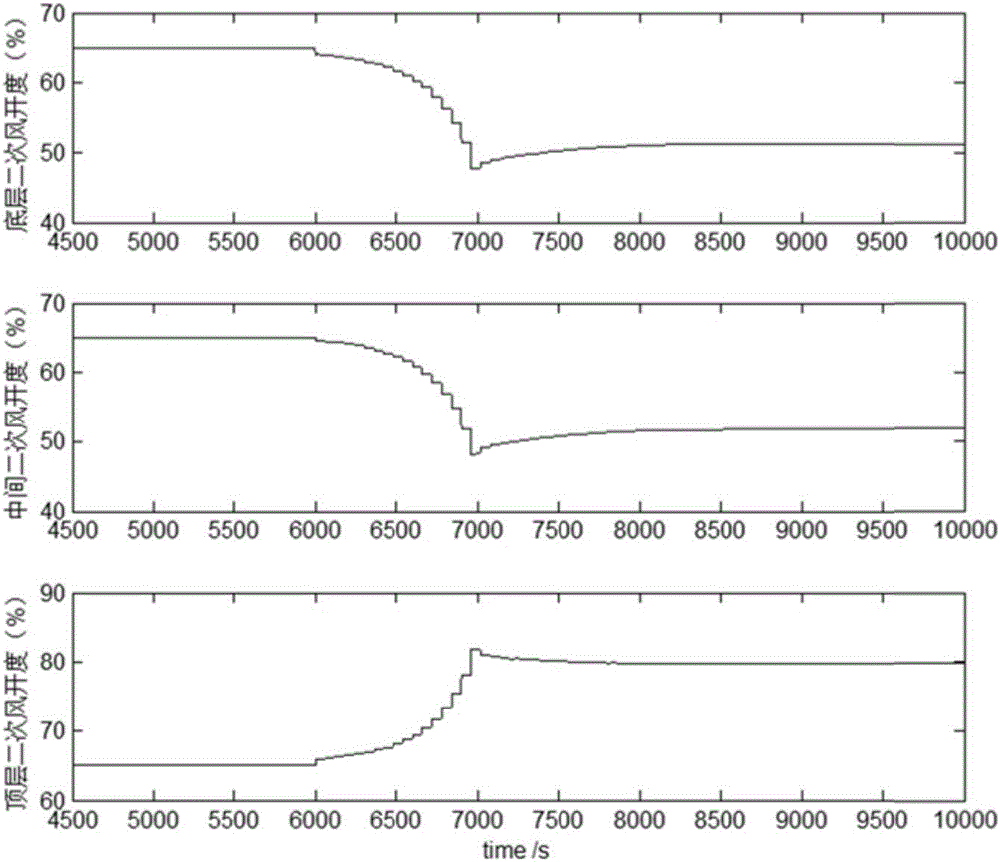

[0055] Embodiment 1 utilizes the present invention to optimize the result such as Figure 3a and Figure 3b As shown, the boiler efficiency has been slightly increased from 94.69% to 94.78%, and the NOX emission has been greatly reduced from 376mg / m3 to 341mg / m3, which fully exerts the efficiency of the low-nitrogen combustion system and saves energy for power plant boilers. To reduce emissions, it is of great significance to achieve optimal combustion and emissions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com