Semiconductor device and manufacturing method thereof, and electronic device

A manufacturing method, semiconductor technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as burden, non-uniform critical dimensions, polysilicon is easy to be oxidized, etc., achieve good performance and yield, double pattern preparation method robust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

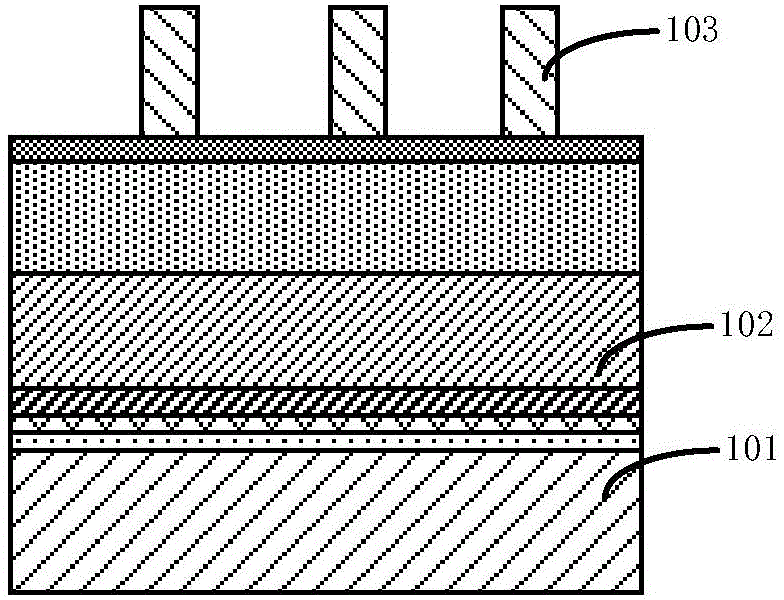

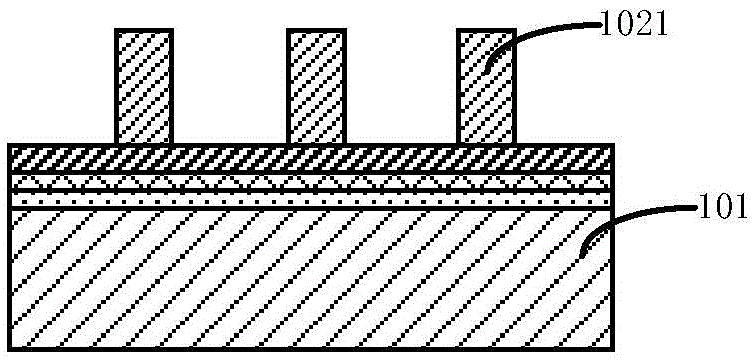

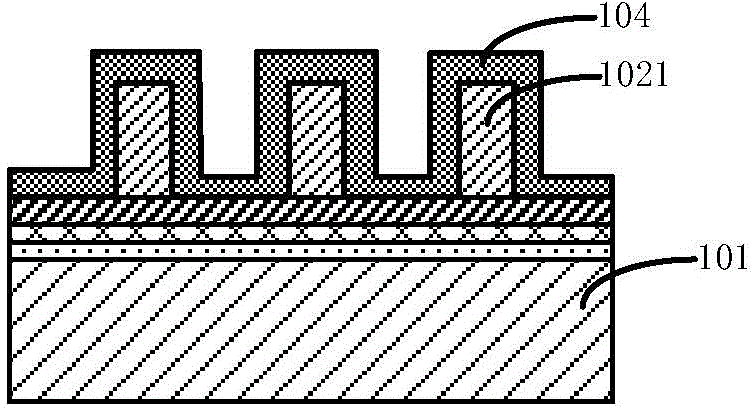

[0046] Attached below Figure 2a-2e The method of the present invention is further explained, wherein Figure 2a-2e It is a schematic diagram of a process of manufacturing a semiconductor device based on a dual pattern method in an embodiment of the present invention.

[0047] First, step 201 is performed to provide a semiconductor substrate 201, on which a doped oxide layer 206, amorphous silicon 202, and a patterned mask layer 203 are formed.

[0048] Specifically, such as Figure 2a As shown, the semiconductor substrate 201 may be at least one of the materials mentioned below: silicon, silicon-on-insulator (SOI), silicon-on-insulator (SSOI), silicon-germanium-on-insulator (S-SiGeOI) ), silicon germanium on insulator (SiGeOI) and germanium on insulator (GeOI), etc.

[0049] Optionally, an isolation structure may also be formed in the semiconductor substrate, and the isolation structure is a shallow trench isolation (STI) structure or a localized silicon oxide (LOCOS) isolation stru...

Embodiment 2

[0083] The present invention also provides a semiconductor device, which is prepared by using the method described in Embodiment 1. The pattern of the semiconductor device prepared by the method of the present invention has good uniformity and consistency, so as to further improve the performance and yield of the semiconductor device.

Embodiment 3

[0085] The present invention also provides an electronic device, including the semiconductor device described in Embodiment 2. Wherein, the semiconductor device is the semiconductor device described in Embodiment 2 or the semiconductor device obtained according to the manufacturing method described in Embodiment 1.

[0086] The electronic device of this embodiment may be any electronic product or equipment such as a mobile phone, a tablet computer, a notebook computer, a netbook, a game console, a TV, a VCD, a DVD, a navigator, a camera, a camcorder, a voice recorder, an MP3, an MP4, a PSP, etc. , Can also be any intermediate product including the semiconductor device. The electronic device of the embodiment of the present invention has better performance due to the use of the above-mentioned semiconductor device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com