A kind of hierarchical structure lithium battery cathode composite material and its preparation method and lithium battery

A composite material and hierarchical structure technology, applied to battery electrodes, secondary batteries, structural parts, etc., can solve problems such as complex methods, difficult regulation, and low output, and achieve improved cycle and rate performance, and improved rapid charge and discharge capabilities , Improve the effect of electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

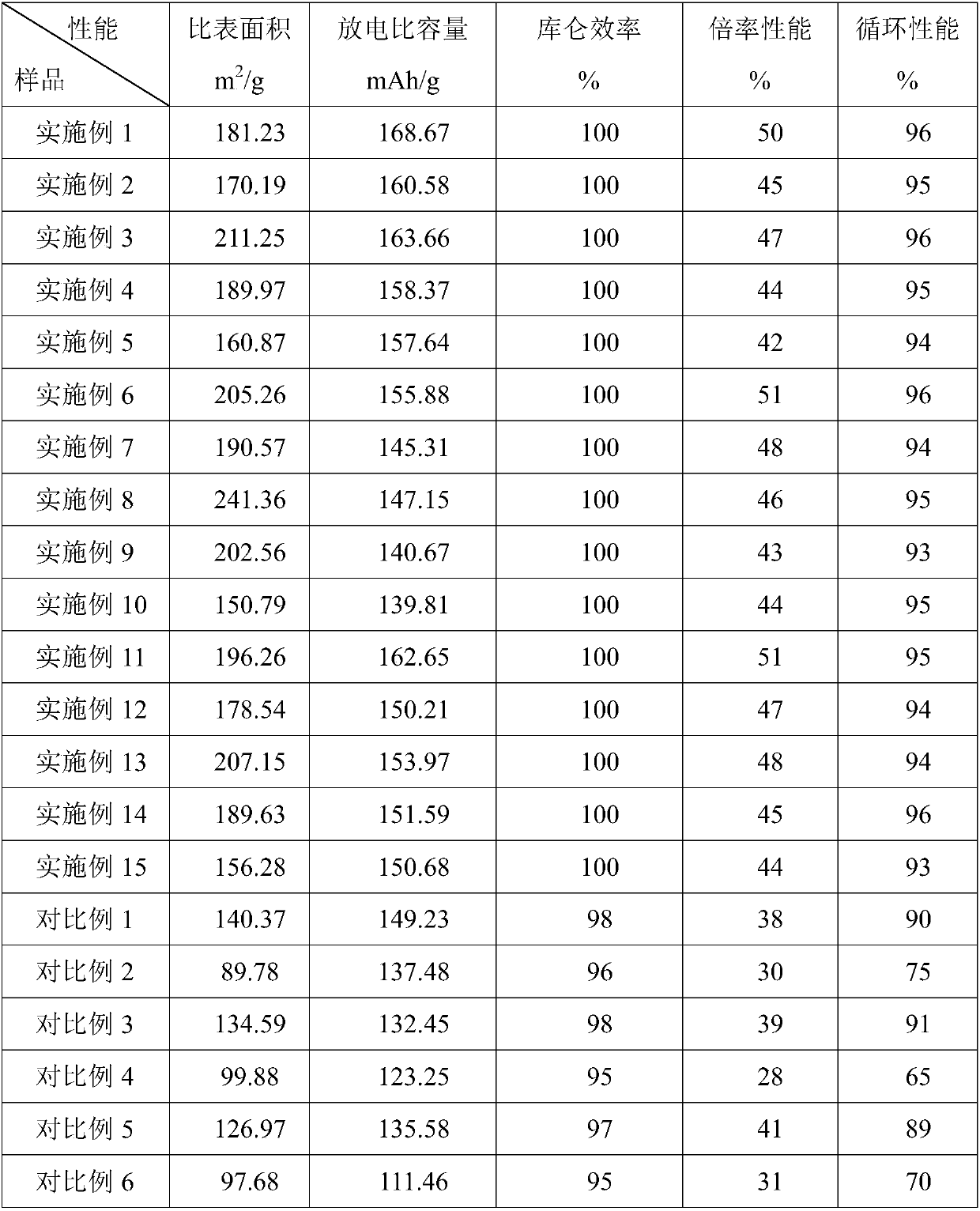

Examples

preparation example Construction

[0081] Another aspect of the present application relates to a method for preparing a positive electrode composite material of a hierarchical structure lithium battery, which is characterized in that it comprises the following steps:

[0082] In step (1), polystyrene microspheres are dispersed in water or DMF to obtain polystyrene dispersion A;

[0083] In step (2), under ultrasonic conditions, the polystyrene dispersion A in step (1) is added to the graphene oxide suspension to obtain a mixed solution B;

[0084] Step (3), dissolving the metal salt and urea in water, and adding them to the mixed solution B obtained in step (2), continuing the ultrasonic dispersion for 1-3 hours, then transferring the reaction solution to an airtight container for hydrothermal or solvothermal reaction , to obtain product C;

[0085] Step (4), adding the product C and lithium salt described in step (3) into a solvent, ultrasonically dispersing, transferring the reaction solution to a closed con...

Embodiment 1

[0094] Example 1: A hierarchical structure lithium iron phosphate / reduced graphene oxide composite material

[0095] Step (1), dispersing polystyrene microspheres with diameters of 90, 350, and 900 nm in DMF to obtain a polystyrene dispersion with a concentration of 2 mg / ml, thereby obtaining A1, A2, and A3 dispersions;

[0096] Step (2), under ultrasonic conditions, add 12ml A1 and 8ml A2 polystyrene dispersion into 40ml of 4mg / ml graphene oxide suspension to obtain mixed solution B1;

[0097] In step (3), 493.10 mg of anhydrous ferric chloride, 431.56 mg of disodium hydrogen phosphate, and 5.48 g of urea were dissolved in water, and added to the mixed liquid B1 obtained in step (2), and after ultrasonic dispersion was continued for 1 h, the reaction liquid was Transfer to an airtight container for solvothermal reaction at 180°C for 24 hours to obtain product C1;

[0098] In step (4), add the product C1 and 72.78 mg of lithium hydroxide described in step (3) into deionized w...

Embodiment 2

[0100] Example 2: A hierarchical structure lithium iron phosphate / reduced graphene oxide composite material

[0101] Step (1), dispersing polystyrene microspheres with diameters of 90, 350, and 900 nm in DMF to obtain a polystyrene dispersion with a concentration of 2 mg / ml, thereby obtaining A1, A2, and A3 dispersions;

[0102] Step (2), under ultrasonic conditions, add 14ml A1 and 6ml A3 polystyrene dispersion into 40ml of 4mg / ml graphene oxide suspension to obtain mixed solution B2;

[0103] In step (3), 493.10 mg of anhydrous ferric chloride, 431.56 mg of disodium hydrogen phosphate, and 5.48 g of urea were dissolved in water, and added to the mixed liquid B2 obtained in step (2), and after ultrasonic dispersion was continued for 1 h, the reaction liquid Transfer to an airtight container for solvothermal reaction at 180°C for 24 hours to obtain product C2;

[0104] In step (4), add the product C2 and 72.78 mg of lithium hydroxide described in step (3) into deionized water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com