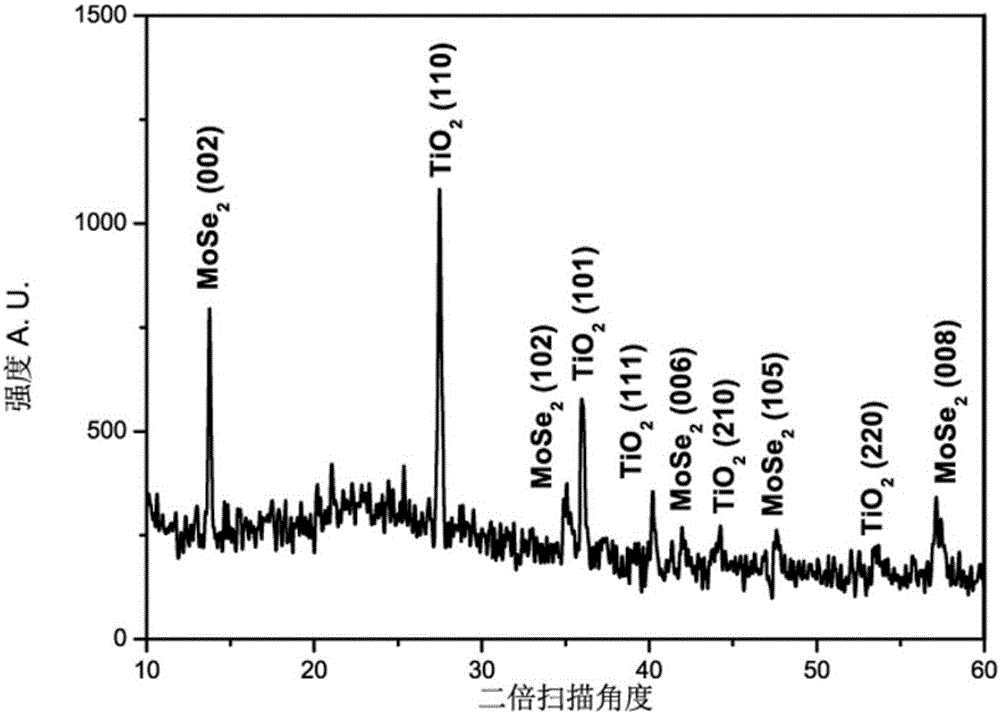

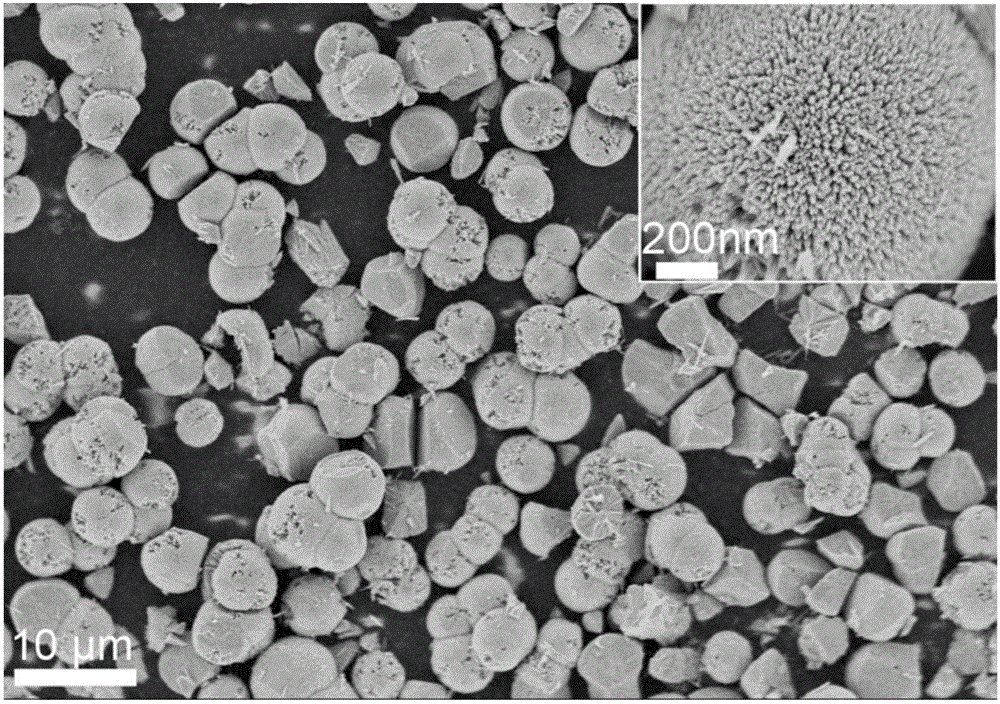

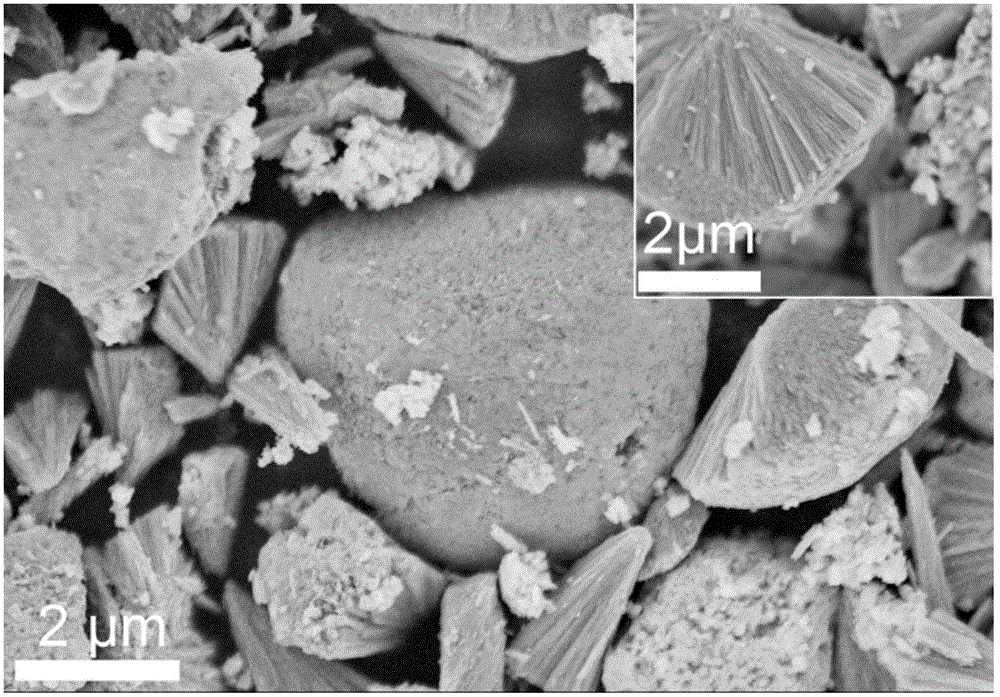

MoSe2 nanosheet composite fireworks-shaped TiO2 nanorod array and preparation method thereof

A nanorod array and fireworks-like technology, which is applied in the field of MoSe2 nanosheet composite fireworks-like TiO2 nanorod array and its preparation, can solve the problems of inapplicability to large-scale industrial production, high production costs, and harsh reaction conditions, and achieve excellent optical performance. Catalytic degradation performance, low cost, and highly reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 prepares MoSe 2 Nanosheet Composite Firework-like TiO 2 nanorod array

[0040] The specific steps of preparation are as follows:

[0041] (1) Add 1mL of 35% hydrochloric acid to the prepared conical flask with a capacity of 20ml, and then add 2mL of tetrabutyl titanate, shake the conical flask slightly by hand to make the solution fully mix and react, and wait until the reaction heat is completely Disperse, slowly drop into 20mL of oleic acid, stir well.

[0042] (2) After stirring for more than 15 minutes, add the mixed solution into a 50mL reaction kettle, seal it, then put it into a vacuum oven and heat it at 180°C for 4 hours, and cool to room temperature after the reaction.

[0043] (3) Carefully collect and take out the milky white precipitate at the bottom of the reaction kettle and the milky white attachment on the inner wall, and wash it repeatedly with absolute ethanol water until the supernatant is completely clear.

[0044] (4) Pour off the ...

Embodiment 2

[0050] Example 2 MoSe of the present invention 2 Nanosheet Composite Firework-like TiO 2 Specific Surface Area Measurement of Nanorod Arrays

[0051] Utilize BET test method to the MoSe of the present invention that above-mentioned embodiment 1 prepares 2 Nanosheet Composite Firework-like TiO 2 The specific surface area of the nanorod array is tested, including specific steps:

[0052] (1) Open the gas, open the nitrogen and helium of the system respectively, and control the air pressure at 0.25MPa.

[0053] (2) Weigh 0.5g and 0.3g of TiO respectively 2 Nanorod arrays and MoSe 2 Nanosheet Composite Firework-like TiO 2 The nanorod array is loaded into the U-shaped tube of the experimental equipment, and the sample is loaded.

[0054] (3) Pour a small amount of liquid nitrogen into a 200ml beaker to cool the beaker, and then add liquid nitrogen to a place 1cm away from the top of the beaker.

[0055] (4) Turn on the instrument switch, adjust the flow ratio of nitrogen ...

Embodiment 3

[0059] Example 3 MoSe of the present invention 2 Nanosheet Composite Firework-like TiO 2 Photocatalytic Degradation Ability Test of Nanorod Arrays

[0060] The MoSe of the present invention prepared in the above-mentioned embodiment 1 2 Nanosheet Composite Firework-like TiO 2 The nanorod array, according to Example 2, has a larger specific surface area. Due to the present invention MoSe 2 Nanosheet Composite Firework-like TiO 2 The specific surface area of the nanorod array is significantly improved after compounding, and a p-n junction is formed at the junction, and the distribution of a large number of quantum dots is conducive to electronic excitation, which makes it compared with pure MoS 2 The photocatalytic performance of nanoflowers has been significantly improved. MoSe of the present invention 2 Nanosheet Composite Firework-like TiO 2 Nanorod arrays, pure TiO 2 Nanorod arrays with MoSe 2 Field emission performance test of nanosheets, including specific step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com