Preparation method for light-pyrolysis carbon black

A shallow cracking, carbon black technology, applied in recycling technology, plastic recycling, fibrous fillers, etc., can solve the problems of reduced thermal cracking carbon black performance, poor thermal cracking carbon black performance, and restricting the development of thermal cracking processes. , to reduce equipment wear, facilitate distillation and recovery, and achieve excellent reinforcement performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method for shallow cracking carbon black, comprising the following steps:

[0030] Step 1: Crushing the truck tires to obtain whole tire rubber powder with a particle size of 30 mesh;

[0031] Step 2: Gradually heat the waste rubber powder to 280°C in the double-screw heating conveying device, then enter the screw extruder at 320°C for shallow cracking and extrusion for 2 minutes, and the extruded product enters a water bath to cool down to obtain shallow cracking rubber;

[0032] Step 3: Wrap the shallow lysate rubber with filter paper, put it into a Soxhlet extractor, and extract it with toluene and other solvents for 48 hours;

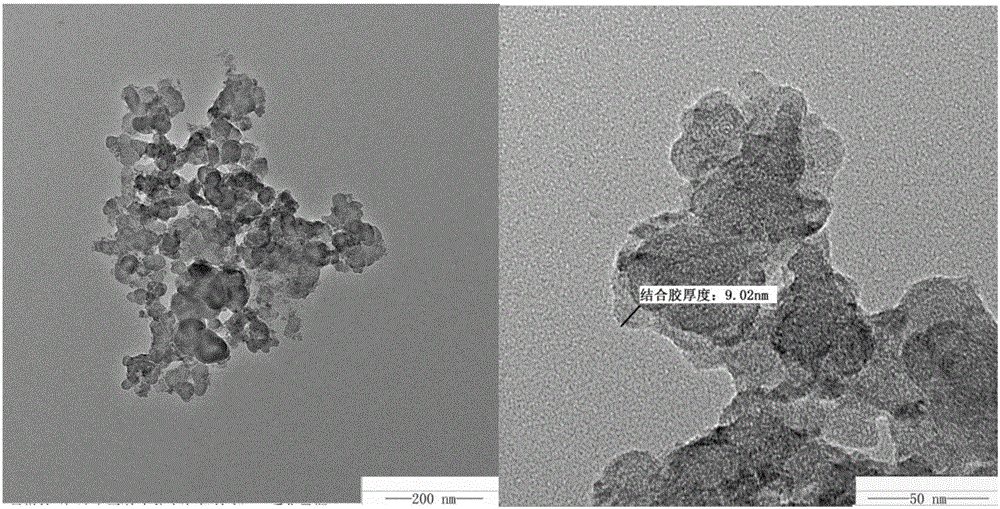

[0033] Step 4: Take out the filter paper and dry it in an oven at 50°C for 1 hour to obtain lightly cracked carbon black and gel products. Wrap the sample in the filter paper with a 400-mesh copper mesh, put it in toluene solvent and sonicate it for 1 hour, and dissolve the solution Put it in a centrifuge, centrifuge at a speed...

Embodiment 2

[0039] A preparation method for shallow cracking carbon black, comprising the following steps:

[0040] Step 1: Crushing the car tires into rubber particles with a size of 5-15 mesh, and further grinding them into rubber powder with a size of 20-80 mesh;

[0041] Step 2: Gradually heat the waste rubber powder to 240°C in the double-screw heating conveying device, then enter the screw extruder to heat up to 270°C for shallow cracking, and the extruded product is cooled in a water bath and extruded for 2 minutes;

[0042]Step 3: Wrap the shallow lysate rubber with filter paper, put it into a Soxhlet extractor, and extract it with a solvent for 24 hours;

[0043] Step 4: Take out the filter paper and dry it in an oven at 60°C for 0.5h to obtain shallow pyrolysis carbon black and gel products. Wrap the sample in the filter paper with a 400-mesh copper mesh and put it in toluene solvent for 0.5h. Put the solution into a centrifuge, centrifuge at a speed of 7000rpm for 30min, colle...

Embodiment 3

[0048] A preparation method for shallow cracking carbon black, comprising the following steps:

[0049] Step 1: Crushing the car tires into rubber particles with a size of 5-15 mesh, and further grinding them into rubber powder with a size of 20-80 mesh;

[0050] Step 2: Gradually heat the waste rubber powder to 280°C in the double-screw heating conveying device, and then enter the screw extruder at a temperature of 350°C for shallow cracking and extruding. The extruded product enters a water bath to cool, and the extrusion time is 2 minutes;

[0051] Step 3: Wrap the shallow lysate rubber with filter paper, put it into a Soxhlet extractor, and extract it with a solvent for 36 hours;

[0052] Step 4: Take out the filter paper and dry it in an oven at 60°C for 1 hour to obtain shallow pyrolysis carbon black and gel products. Wrap the sample in the filter paper with a 400-mesh copper mesh, put it in gasoline and ultrasonically for 0.5 hours, and dissolve the solution Put it in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com