Self-thermal insulation wall assembled by prefabricated wallboard components

A prefabricated, self-insulating technology, applied in roofs using tile/slate tiles, roofs using flat/curved panels, building components, etc., can solve problems such as poor controllability, loss of energy-saving and thermal insulation functions, and strong implementation techniques.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The invention will be further described below in conjunction with the accompanying drawings.

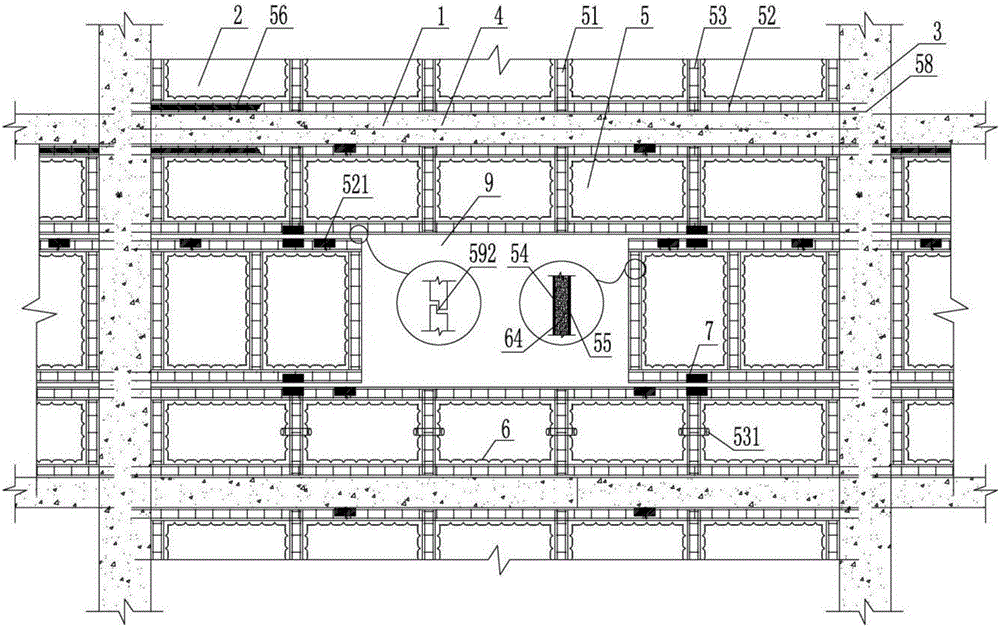

[0023] figure 1 It is a plan view of a self-insulating wall combined with prefabricated assembled wallboard components of the present invention. When the present invention is implemented, the prefabricated assembled wallboard components 2 produced in the factory assembly line are hoisted to the pouring site of the frame column 3, and the prefabricated assembled wallboard components 2 are transported to the pouring site of the frame column 3. Some components 2 and exposed rib steel bars 58 of the assembled wall panel component 2 are embedded in the column mold for on-site casting. When the columns and beams are shaped steel structures, the exposed rib steel bars are directly welded to the shaped steel columns and shaped steel beams; the prefabricated assembled wall panel member 2 can be designed as a horizontal slab in the best state or as a vertical slab; two pieces The adjac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com