Nano flower-shaped ultramicro gold electrode and preparation and application thereof

A gold electrode and flower-like technology, applied in the research field, can solve the problems of hindering the popularization and application of gold ultra-micro electrodes, high requirements on instruments and equipment, and large substrate volume, and achieves low cost, simple preparation method, and small size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

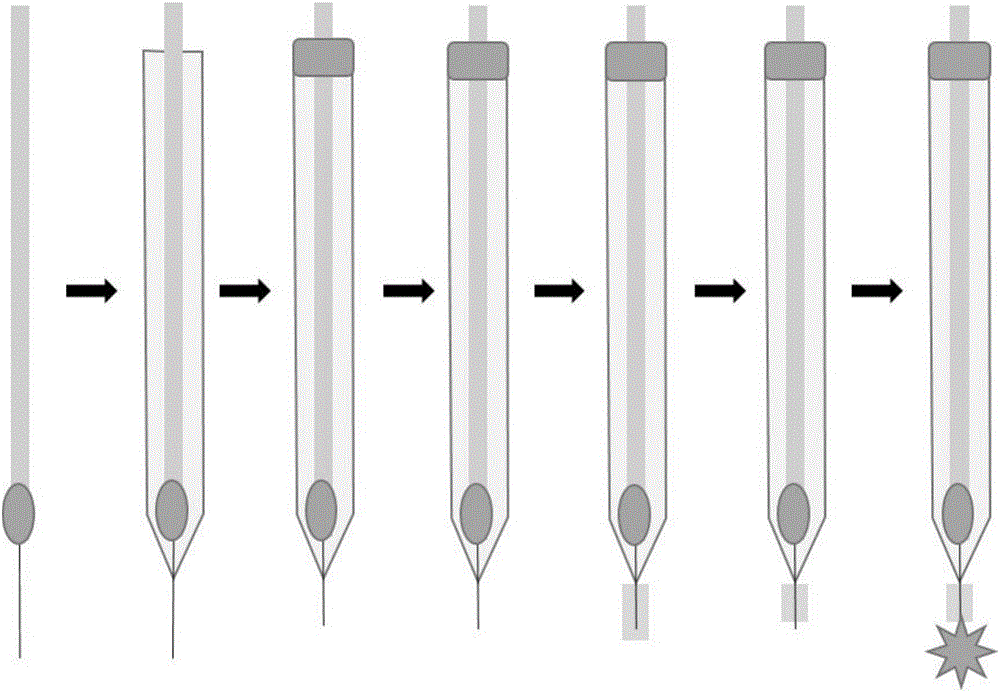

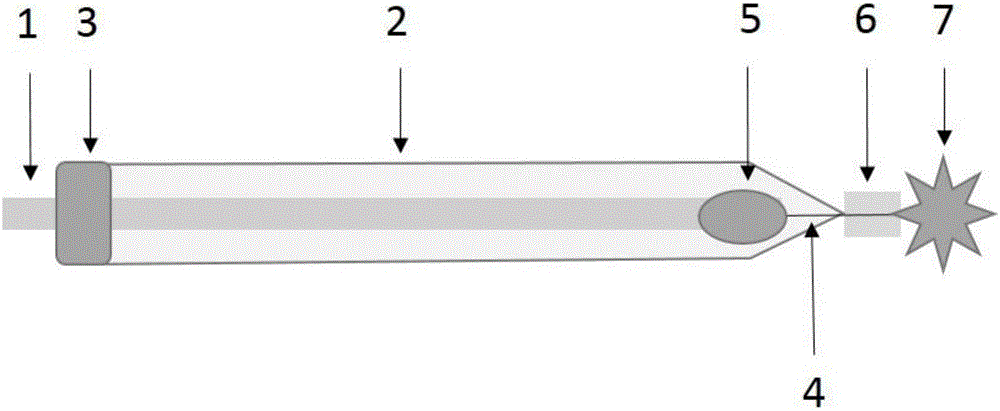

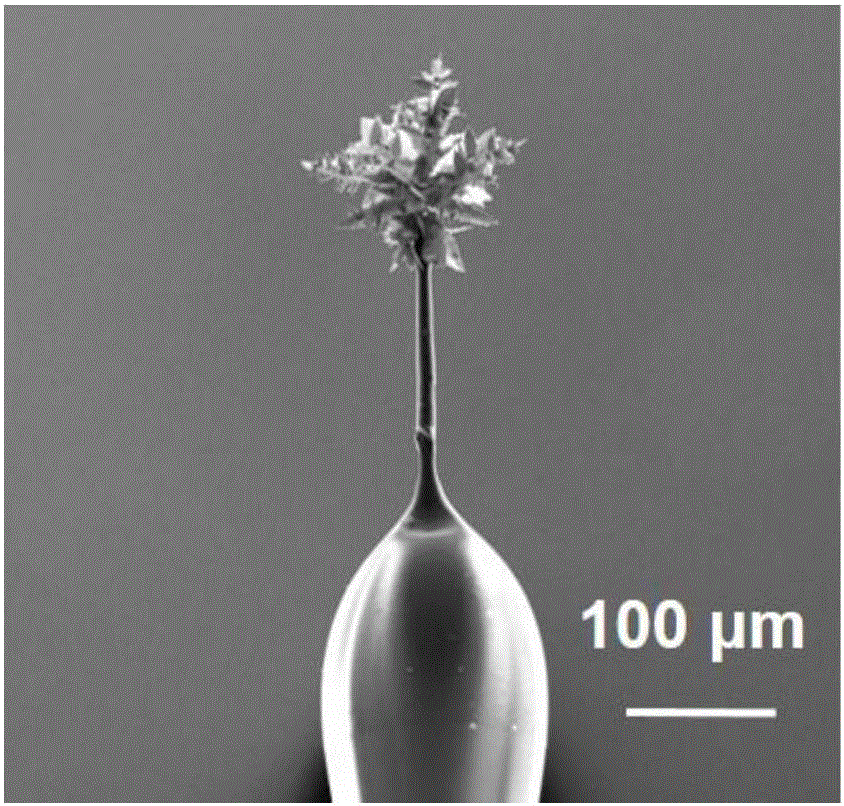

[0046] figure 1 It is a schematic diagram of the preparation of the nanoflower-shaped ultrafine gold electrode of the present invention. In this embodiment, the preparation process for preparing nano-flower-shaped ultrafine gold electrodes is as follows:

[0047] Step 1: Cut the 7μm carbon fiber 4 into short sections with a length of 1.5cm to 2cm, ultrasonically clean it with acetone, ethanol and ultrapure water for 3 minutes, then wash it with ultrapure water for 3 times, and dry it in a 37°C thermostat . Cut a copper wire 1 with a length of about 10 cm, and use graphite conductive glue 5 to adhere it to the cleaned and dried carbon fiber 4 .

[0048] Step 2: Draw one end of the glass capillary 2 with a diameter of 0.8 mm to a tip inner diameter of about 50 μm, and use a copper wire 1 bonded with carbon fiber 4 to penetrate through the thicker end of the glass capillary 2, exposing the tip of about 0.5 mm.

[0049] Step 3: The tail of the glass capillary 2 is sealed with e...

Embodiment 2

[0060] In this embodiment, the preparation process for preparing nano-flower-shaped ultrafine gold electrodes is as follows:

[0061] Step 1: Cut the 7μm carbon fiber 4 into short sections with a length of 1.5cm to 2cm, ultrasonically clean it with acetone, ethanol and ultrapure water for 3 minutes, then wash it with ultrapure water for 5 times, and dry it in a 37°C thermostat . Cut a copper wire 1 with a length of about 8 cm, and use graphite conductive glue 5 to adhere it to the cleaned and dried carbon fiber 4 .

[0062] Step 2: Draw one end of the glass capillary 2 with a diameter of 1.5 mm to a tip inner diameter of about 100 μm, and use a copper wire 1 bonded with carbon fiber 4 to penetrate through the thicker end of the glass capillary 2, exposing the tip of about 0.5 mm.

[0063] Step 3: The tail of the glass capillary 2 is sealed with epoxy resin 3 .

[0064] Step 4: After melting and sealing the tip of the capillary 2 with an alcohol lamp, continue to flame-etch t...

Embodiment 3

[0069] In this embodiment, the preparation process for preparing nano-flower-shaped ultrafine gold electrodes is as follows:

[0070] Step 1: Cut the 7μm carbon fiber 4 into short sections with a length of 1.5cm to 2cm, ultrasonically clean it with acetone, ethanol and ultrapure water for 3 minutes, then wash it with ultrapure water for 3 times, and dry it in a 37°C thermostat . Cut a copper wire 1 with a length of about 10 cm, and use graphite conductive glue 5 to adhere it to the cleaned and dried carbon fiber 4 .

[0071] Step 2: Draw one end of the glass capillary 2 with a diameter of 0.8 mm to a tip inner diameter of about 50 μm, and use a copper wire 1 bonded with carbon fiber 4 to penetrate through the thicker end of the glass capillary 2, exposing the tip of about 0.5 mm.

[0072] Step 3: The tail of the glass capillary 2 is sealed with epoxy resin 3 .

[0073] Step 4: After melting and sealing the tip of the capillary 2 with an alcohol lamp, continue to flame-etch t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com