Ionic liquid covalently modified graphene-exfoliated hydrotalcite-like bifunctional oxygen catalyst and its preparation method and application

A technology of covalent modification and ionic liquid, which is applied in the direction of structural parts, electrical components, battery electrodes, etc., to achieve the effects of low preparation cost, good OER and ORR activity, and easy purchase and preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

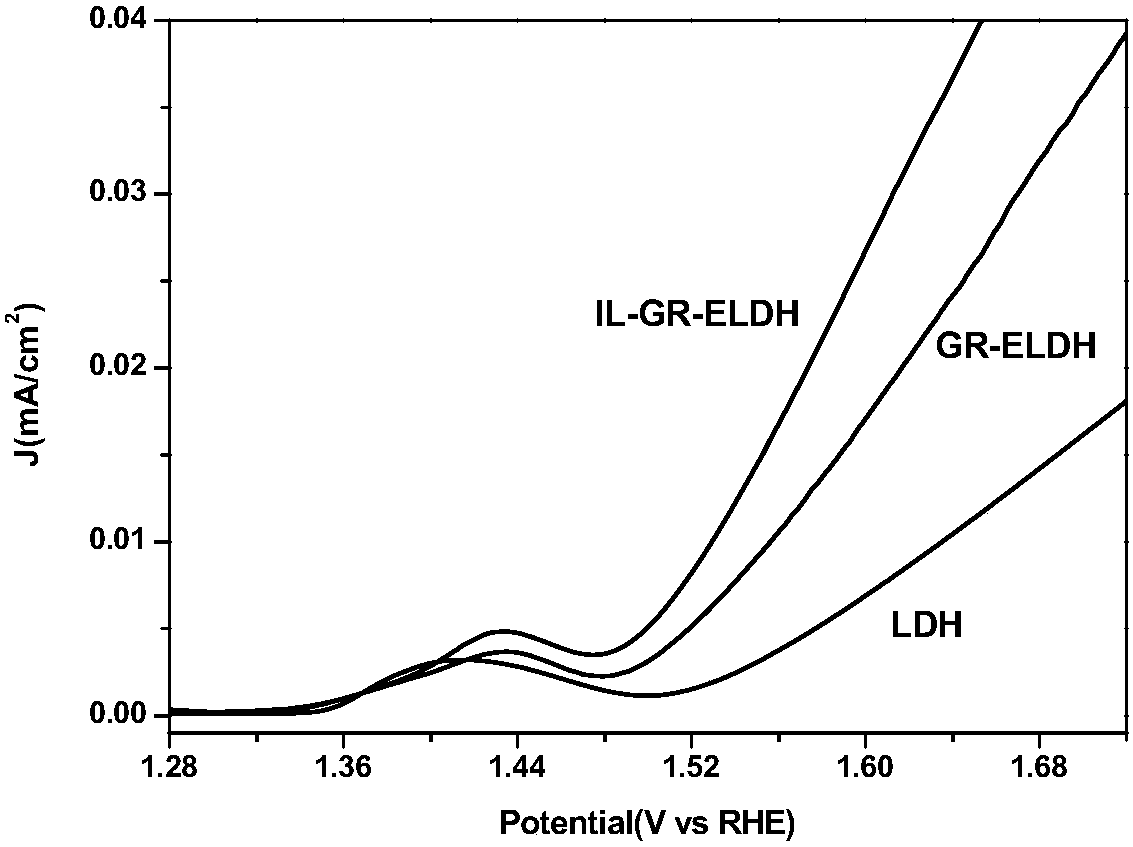

[0035] (a) Preparation of ELDH nanosheets

[0036] Dissolve nickel chloride hexahydrate and ferric chloride hexahydrate in a molar ratio of 3:1 in 64mL of ultrapure water, so that the total concentration of metal ions is 0.02mol / L, stir to dissolve completely, and then slowly mix 14mL. .2M urea and 2mL0.01M trisodium citrate, the mixed solution was transferred to the reaction kettle, and reacted at 150°C for 24h. After the reaction solution was centrifuged, it was washed three times with deionized water and ethanol respectively, and the obtained CO 3 2- -LDH is dispersed in a mixed aqueous solution of 1mol / L NaCl and 3.3mmol / L HCl, N 2 Stirred under the atmosphere for 12 hours, after suction filtration, Cl - -LDH, and then dispersed in NaNO with a concentration of 0.1mol / L 3 In aqueous solution, N 2 Stir under atmosphere for 12 hours, then dry at room temperature for 12 hours after suction filtration to obtain NO 3 - -LDH, and then a certain amount of NO 3 - -LDH hybri...

Embodiment 2

[0042] (a) Preparation of ELDH nanosheets

[0043] Prepared according to the method and conditions of step (a) in Example 1;

[0044] (b) Preparation of GO-ELDH complex

[0045] Prepared according to the method and conditions of step (b) in Example 1;

[0046] (c) Preparation of IL-GR-ELDH hybrid material

[0047] Weigh 40 mg of the GO-ELDH hybrid obtained in step (b) and disperse it in deionized water to make the concentration 0.5 mg / mL, slowly add 20 mg IL and 20 mg KOH, and then sonicate for 30 min; Heat and stir at ℃ for 24h, centrifuge at 4000rpm for 5min, wash with water and absolute ethanol three times in turn, the obtained black solid particle is the IL-GR-ELDH complex, and its specific surface area is 196.37m 2 / g, the average particle size is between 610nm and the monodispersity index is 0.296.

Embodiment 3

[0049] (a) Preparation of ELDH nanosheets

[0050] Dissolve nickel chloride hexahydrate and ferric chloride hexahydrate in a molar ratio of 3:1 in 64mL of ultrapure water, so that the total concentration of metal ions is 0.02mol / L, stir to dissolve completely, and then slowly mix 14mL. .2M urea and 2mL0.01M trisodium citrate, the mixed solution was transferred to the reaction kettle, and reacted at 150°C for 24h. After the reaction solution was centrifuged, it was washed three times with deionized water and ethanol respectively, and the obtained CO 3 2- -LDH is dispersed in a mixed aqueous solution of 1mol / L NaCl and 3.3mmol / L HCl, N 2 Stirred under the atmosphere for 12 hours, after suction filtration, Cl - -LDH, and then dispersed in NaNO with a concentration of 0.1mol / L 3 In aqueous solution, N 2 Stir under atmosphere for 12 hours, then dry at room temperature for 12 hours after suction filtration to obtain NO 3 - -LDH, and then a certain amount of NO 3 - -LDH hybri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com