Filter circuit of high-voltage drive circuit and high-voltage drive circuit

A high-voltage drive circuit and filter circuit technology, which is applied in logic circuits, electrical components, and electric pulse generation, can solve the problems of fast turn-on speed, driving influence, and slow turn-off speed, and achieve accurate differential mode noise filtering ability, Improves noise filtering efficiency and prevents noise interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

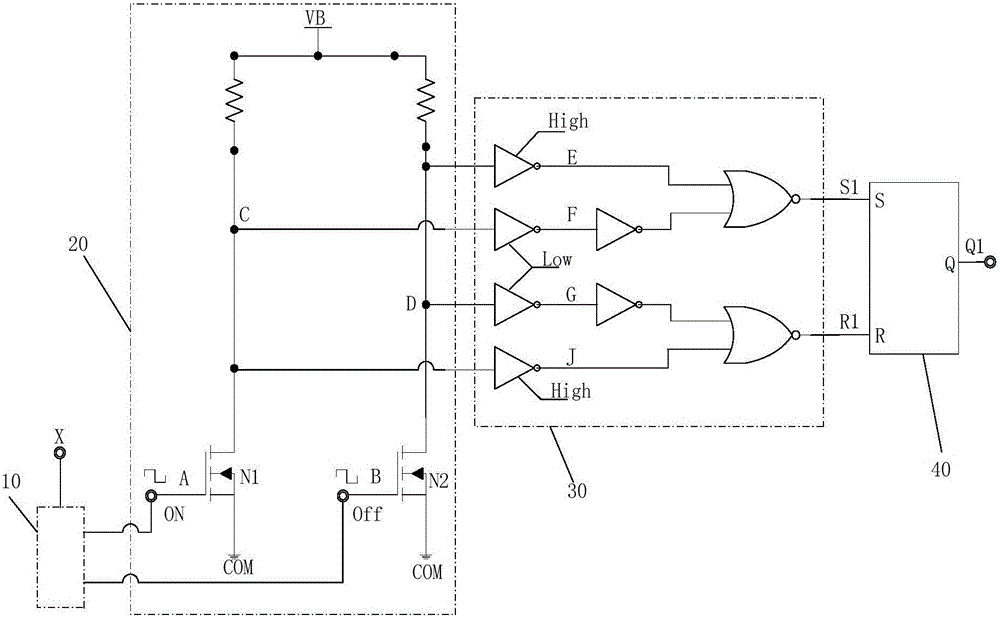

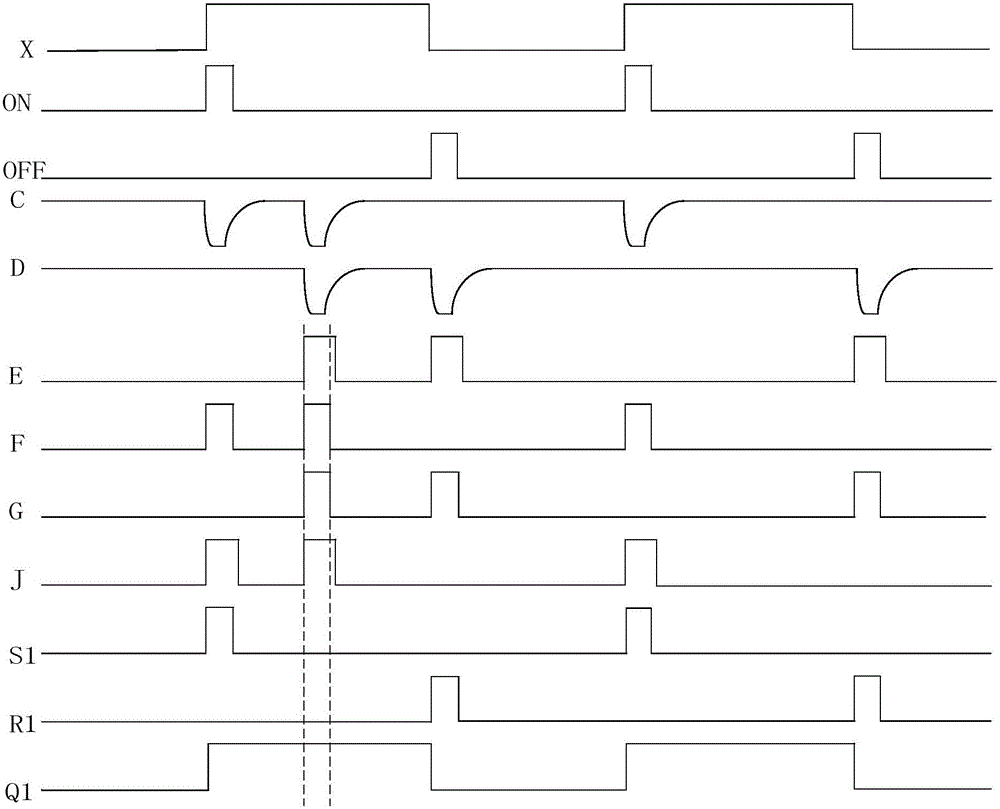

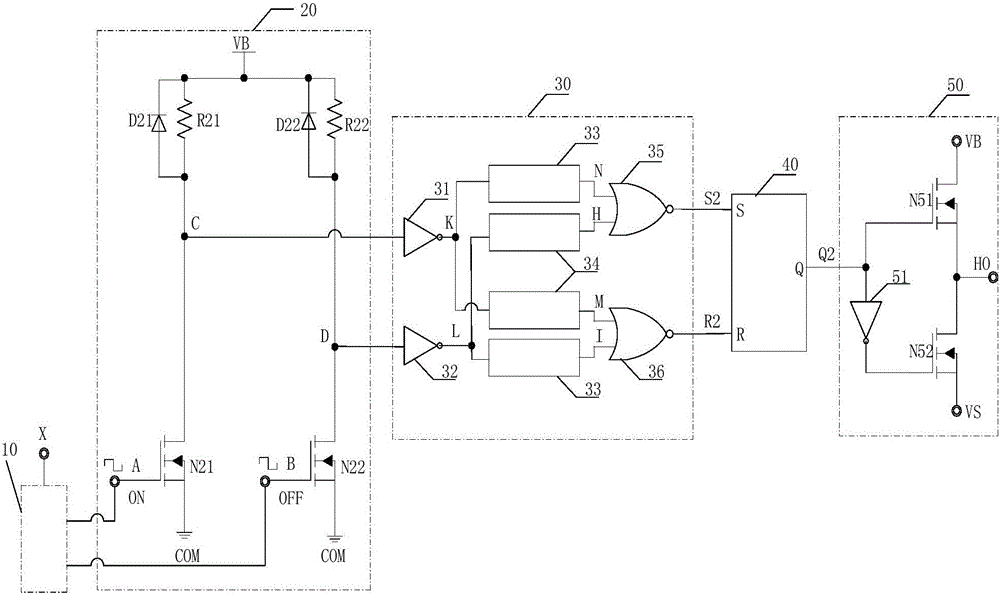

[0043] image 3 and Figure 4 A schematic diagram and a signal logic diagram of the high-voltage drive circuit in this embodiment are shown respectively. The high voltage driving circuit includes a narrow pulse signal generating circuit 10 , a level shifting circuit 20 , a filter circuit 30 , an RS flip-flop 40 and a current amplifying circuit 50 .

[0044] The input end of the narrow pulse signal generation circuit 10 is used to receive the original pulse signal X of 0-15V, and the rising edge narrow pulse signal ON and the falling edge narrow pulse signal are generated respectively on the rising edge and falling edge of the original pulse signal X of 0-15V OFF, and output a narrow pulse signal ON with a rising edge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com