CoP/CdS composite photocatalyst as well as preparation and application thereof

A catalyst and composite light technology, applied in the direction of physical/chemical process catalysts, hydrogen/synthesis gas production, chemical instruments and methods, etc., can solve the problems of high price, increased cost of photocatalytic water splitting, and low reserves of precious metal materials, etc., to achieve The preparation method is simple and easy, and the effect of high photocatalytic water splitting hydrogen production activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

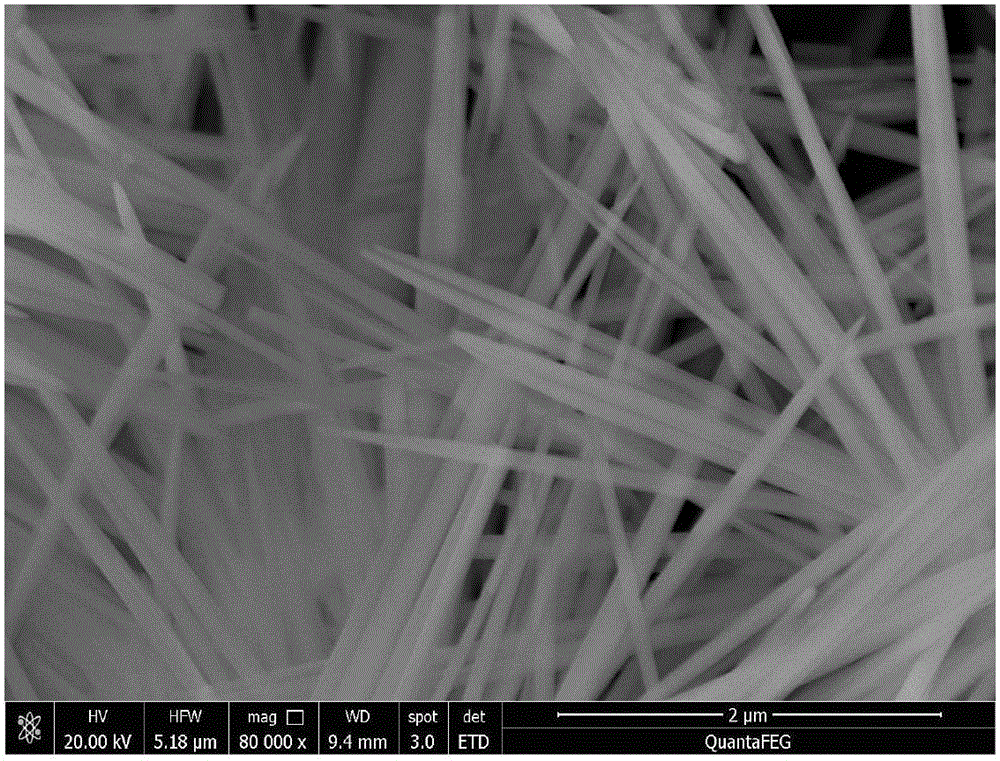

[0023] Preparation of CoP precursor: weigh 2.18g Co(NO 3 ) 2 ·6H 2 O, 1.35g urea, 1.17g NaCl, measure 0.25mL surfactant PEG, add 75mL deionized water, then heat in a 70°C water bath for 30min while stirring, then transfer to a 100mL autoclave, react at 120°C for 5h, Naturally cool to room temperature, wash with deionized water and ethanol, and finally put it in an oven to dry at 80°C, take it out and grind it.

[0024] From figure 1 It can be seen that the CoP precursor is needle-shaped.

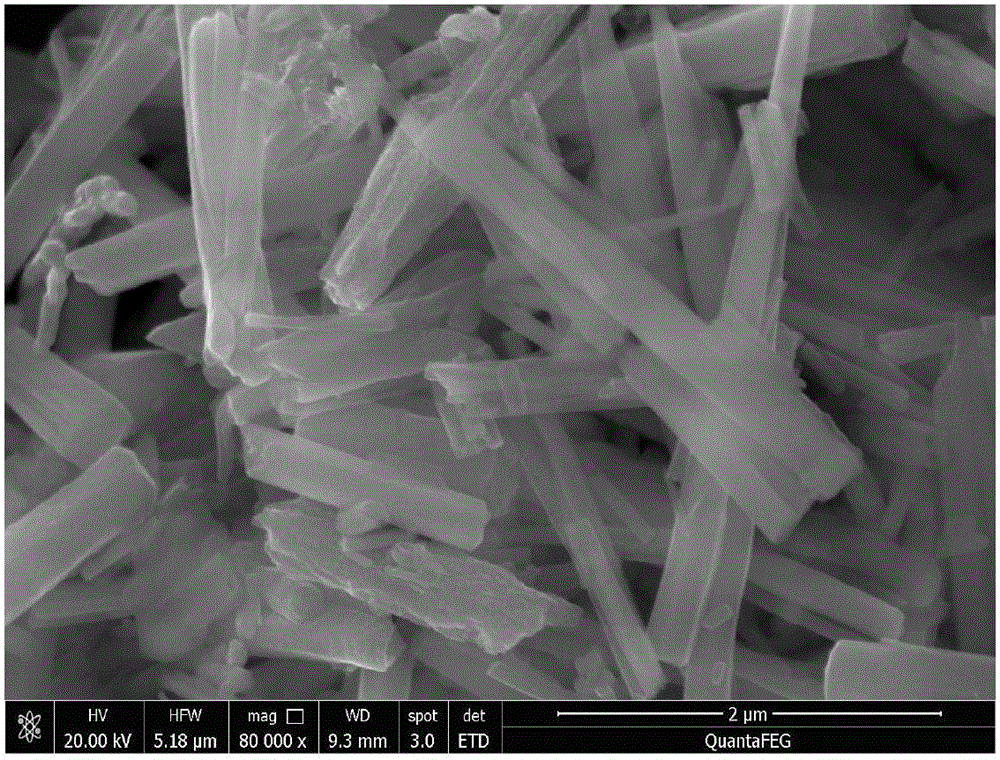

[0025] Preparation of CoP: The above precursor and sodium hypophosphite were weighed according to the molar ratio of Co:P of 1:5, placed in two porcelain boats respectively, and phosphating in a tube furnace at 300°C for 2h under a nitrogen atmosphere. Cool to room temperature under the protection of nitrogen, and then passivate it with passivation gas (nitrogen containing 1% V / V oxygen) to obtain CoP.

[0026] From figure 2 It can be seen that the needle-like structure is severely da...

Embodiment 2

[0031] Similar to Example 1, the point of difference from Example 1 is that the loading amount of CoP is different.

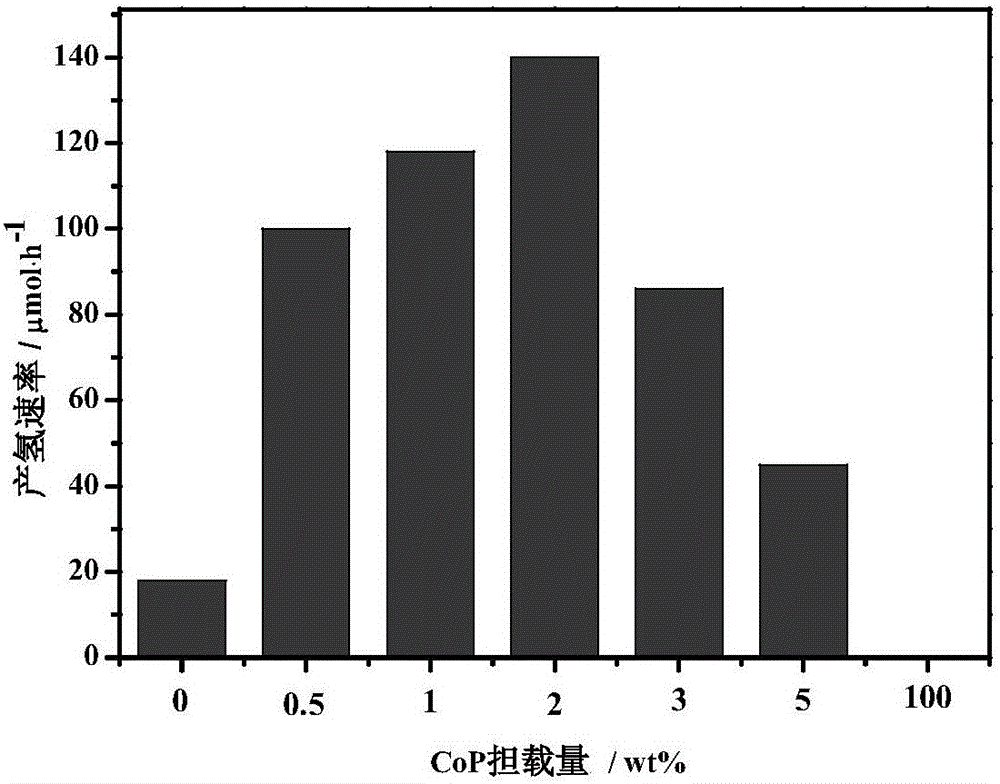

[0032] From image 3 It can be seen that the hydrogen production activity of CdS of CoP is significantly increased. When the loading amount was 2%, the photocatalytic hydrogen production activity of CoP / CdS was the best. Below or above 2%, the hydrogen production activity will decrease.

Embodiment 3

[0034] Same as Example 1, the difference from Example 1 is that the co-catalyst is noble metal Pt, and its loading amount is 2%.

[0035] From Figure 4 It can be seen that the photocatalytic hydrogen production activity of CdS can be significantly improved by loading CoP and Pt (supported by photodeposition reduction method), and the photocatalytic hydrogen production activity of CoP / CdS is twice that of Pt / CdS.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com