Extrusion forming method for A356 aluminum alloy

An extrusion molding and aluminum alloy technology, which is applied in the field of non-ferrous metal processing and molding, can solve the problems of low tensile strength and elongation, and achieve the effects of improving mechanical properties, facilitating control, and increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A356 aluminum alloy hot extrusion molding method, the method comprises the following steps:

[0031] (1) Preparation of extruded ingot: put the commercial A356 aluminum alloy ingot into a resistance furnace and heat it to 750°C to melt, pour the alloy liquid into the mold at a pouring temperature of 750°C, and cast a diameter of 125mm and a height of 100mm The A356 aluminum alloy extruded ingot, the surface oxide skin is removed by car to remove 1-2mm, and the surface impurities are removed.

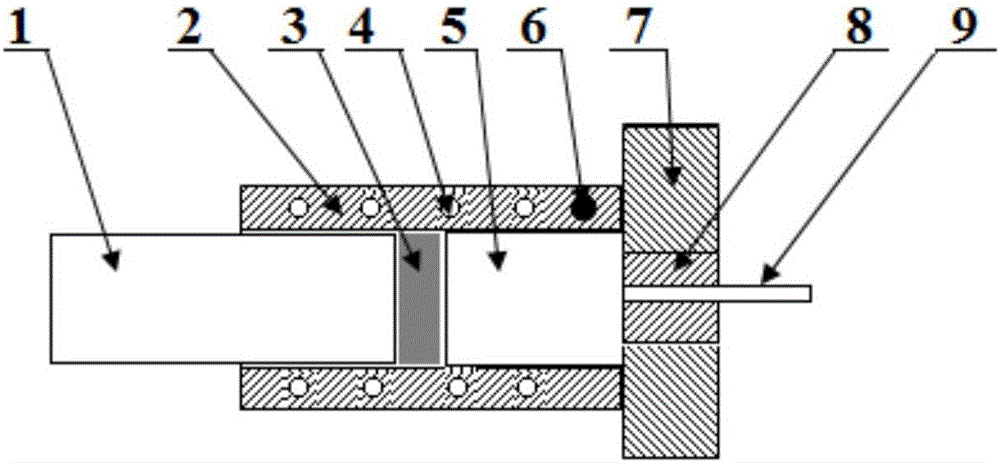

[0032] (2) Preheat the extruded ingot to realize the homogenization treatment of the alloy. The preheating temperature is 400° C. and the holding time is 8 hours. The temperature of the preheated extrusion barrel, extrusion pad and extrusion die is 450°C.

[0033] (3) Hot extrusion process: Put the preheated extrusion die into the extrusion die cavity, and quickly extrude the preheated A356 extrusion billet and extrusion pad into the preheated extrusion barrel for extrusion. Th...

Embodiment 2

[0038] A356 aluminum alloy hot extrusion molding method, the method comprises the following steps:

[0039] (1) Preparation of extruded ingot: put the commercial A356 aluminum alloy ingot into a resistance furnace and heat it to 650°C to melt, pour the alloy liquid into the mold at a pouring temperature of 650°C, and cast an A356 aluminum alloy with a diameter of 125mm Extrude the ingot, and remove the surface scale by 1-2 mm to remove surface impurities.

[0040] (2) Preheating the extruded ingot to realize the homogenization treatment of the alloy, the preheating temperature is 480°C, and the holding time is 2h. The temperature of the preheated extrusion barrel, extrusion pad and extrusion die is 400°C.

[0041] (3) Hot extrusion process: Put the preheated extrusion die into the extrusion die cavity, and quickly extrude the preheated A356 extrusion billet and extrusion pad into the preheated extrusion barrel for extrusion. The extrusion ratio is 60, and the extrusion spee...

Embodiment 3

[0044] A356 aluminum alloy hot extrusion molding method, the method comprises the following steps:

[0045] (1) Preparation of extruded ingot: put the commercial A356 aluminum alloy ingot into a resistance furnace and heat it to 700°C to melt, pour the alloy liquid into the mold at a pouring temperature of 700°C, and cast an A356 aluminum alloy with a diameter of 125mm Extrude the ingot, and remove the surface scale by 1-2 mm to remove surface impurities.

[0046] (2) Preheat the extruded ingot to realize the homogenization treatment of the alloy. The preheating temperature is 450° C. and the holding time is 5 hours. The temperature of the preheated extrusion cylinder, extrusion pad and extrusion die is 430°C.

[0047] (3) Hot extrusion process: Put the preheated extrusion die into the extrusion die cavity, and quickly extrude the preheated A356 extrusion billet and extrusion pad into the preheated extrusion barrel for extrusion. The extrusion ratio is 70, and the extrusion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com