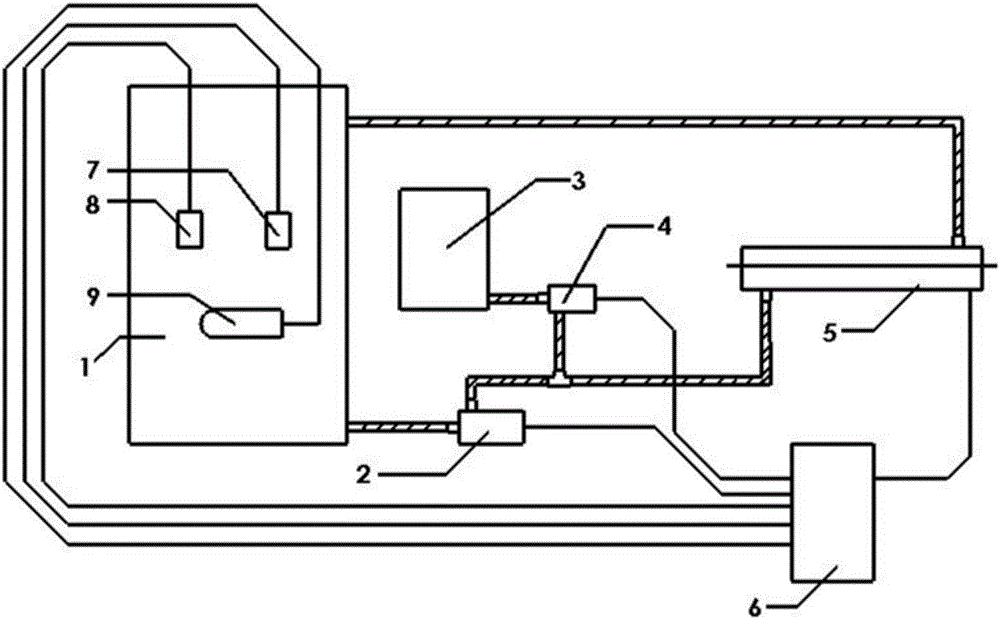

Electromagnetism and ultraviolet ray cooperated organic wastewater treatment device and method

A technology for co-processing and organic wastewater, applied in chemical instruments and methods, magnetic field/electric field water/sewage treatment, water/sewage treatment, etc. Short life, reduced photoelectric conversion efficiency and other problems, to achieve the effects of compact reactor structure, high photoelectric conversion efficiency, and improved photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

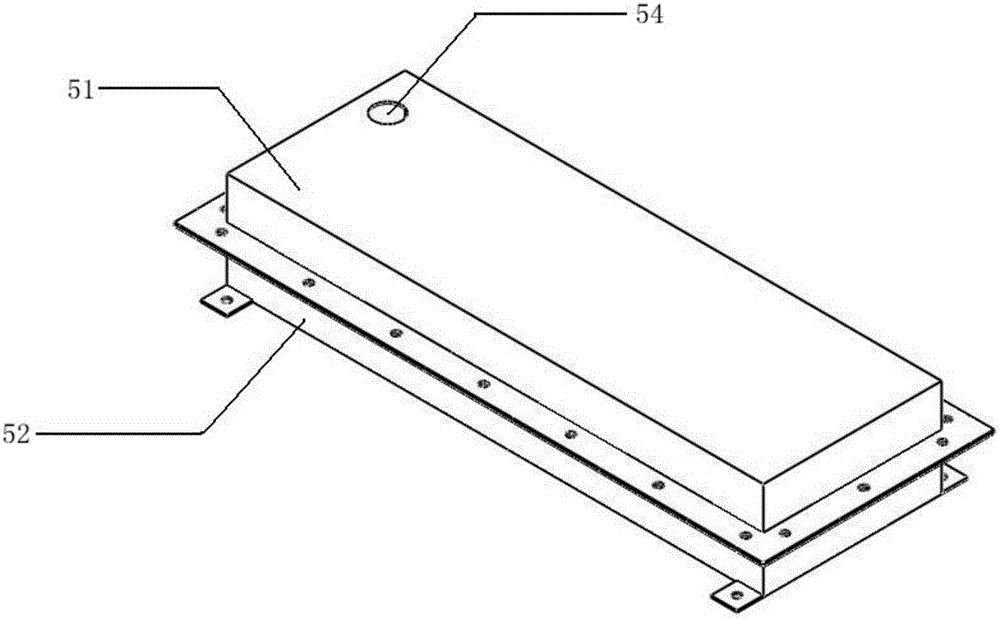

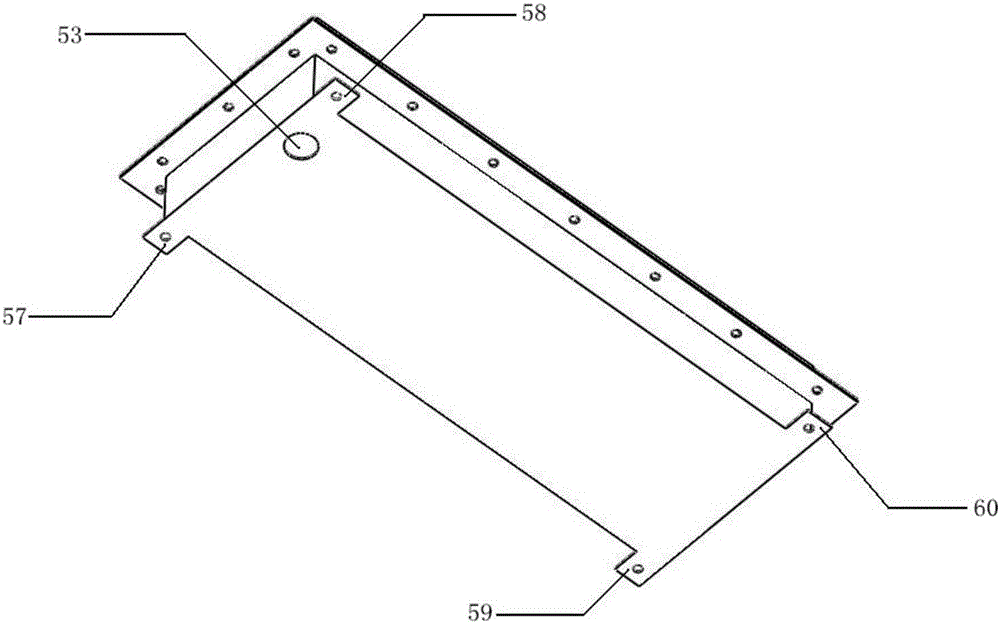

Method used

Image

Examples

Embodiment 1

[0046] 300W rectangular magnetically excited electrodeless ultraviolet lamp and stainless steel sealed reactor are used to treat 20 liters of high-concentration dyeing wastewater with a COD concentration of 4500mg / L. During the reaction, adjust the pH of the wastewater to 3-6 and maintain the temperature at 40-50 ℃, add 27.5% hydrogen peroxide in total 200ml, after 2 hours of circulation reaction, COD is treated to 250mg / L, and the removal rate reaches 95%.

Embodiment 2

[0048] A 100W annular magnetically excited electrodeless ultraviolet lamp is used, glass is used as the reactor shell, and polytetrafluoroethylene is used for the sealing part, which is used to treat 10 liters of electroless nickel plating waste liquid with a COD concentration of 70000mg / L. During the reaction process, the pH of the waste water is adjusted to 4 Between -5, keep the temperature at 60-80°C, add 27.5% hydrogen peroxide for a total of 2 liters, after 3 hours of circulation reaction, COD is reduced to 3000mg / L, and the removal rate is 95%.

Embodiment 3

[0050] Two 500W rectangular magnetically excited electrodeless ultraviolet lamps are used, respectively placed in stainless steel sealed reactors, and the two reactors are connected in parallel to treat 200L electroplating zinc-nickel alloy wastewater. During the reaction, adjust the pH to 10-11 and maintain the temperature At 30-40°C, add a total of 2 liters of 10% sodium hypochlorite solution, and after 4 hours of circular reaction, the COD is reduced from 2600 mg / L to less than 100 mg / L, and the removal rate is 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com