Refining method of Idesia polycarpa edible oil

A technology of sycamore oil and edible oil, which is applied in the directions of fat oil/fat refining, fat oil/fat production, and fat production, etc., can solve the problems of reducing the quality of sycamore oil, low oil yield, impurities, etc., and achieves the improvement of white clay Effectiveness of utilization rate, increased oil yield and low acid return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

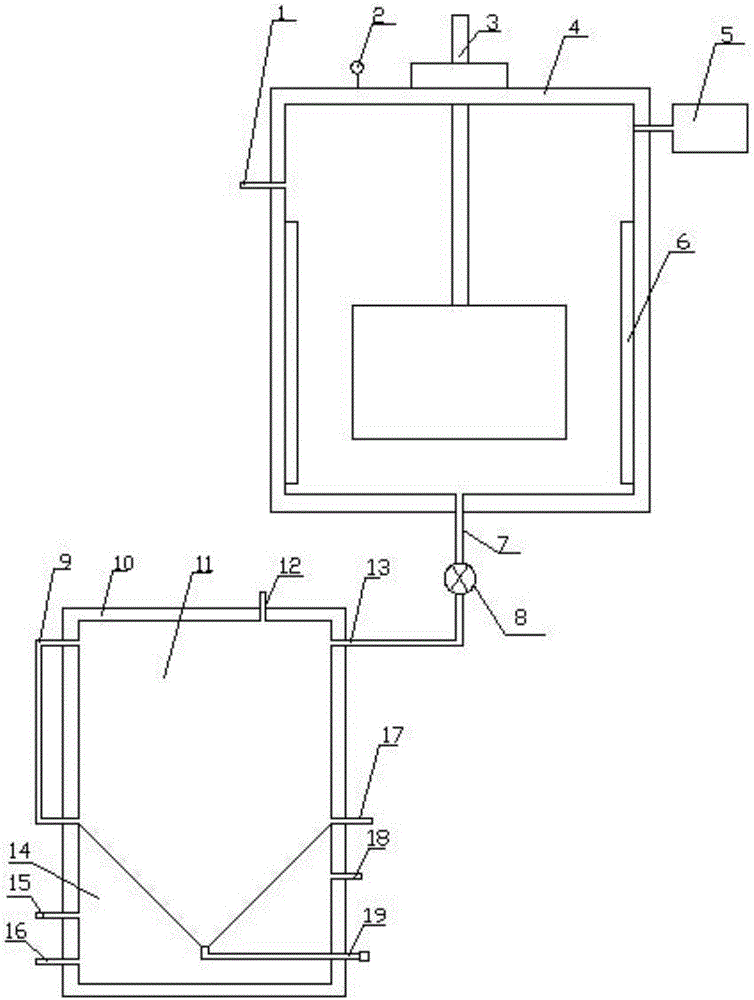

Image

Examples

preparation example Construction

[0037] Step A, the preparation of Jatropha jatropha crude oil;

[0038]Step B, carry out the degumming process to the Jatropha jatropha crude oil obtained in the step A, the process is as follows:

[0039] Heat the Jatropha crude oil. When the oil temperature rises to 40°C, start heating water and stir for 35-45 minutes. The temperature of the hot water is 5-15°C higher than the oil temperature. The content of the hot water is the phospholipid content of the Jatropha crude oil 4.5 ~5.5 times; then raise the oil temperature to 55°C, add an oxalic acid solution with an oil weight of 3%~8% and a concentration of 25%~35%, and stir for 30~40min to obtain degummed oil. The stirring speed of the above stirring is 60~70rpm;

[0040] Step C, deacidifying the degummed jatropha oil obtained in step B, the process is as follows: heating the degummed jatropha oil obtained in step B to 85-90°C, adding 0.05-0.06% of the oil weight to a concentration of 70 % phosphoric acid, after homogeneou...

Embodiment 1

[0046] Select Jatropha jatropha fruits, remove the deteriorated Jatropha jatropha fruits and foreign matter, so that the impurity content is ≤2%; soak the selected Jatropha jatropha fruits in 0.6% dilute lye at 50°C for not less than 30 minutes, and then immerse them in cold water Rinse the jatropha fruit; then dry the peeled jatropha fruit and press it in an extruder at room temperature. The walnut kernels are divided into 15KG bags and put into the mold of the extruder. Separation of slices; pressing adopts segmental boosting method, the pressure of the pre-pressing section with a pressure of 10MPa is boosted at a speed of 4MPa / min, and the pressure is raised to 40MPa to release the pressure and discharge; the squeezed jatropha oil is filtered to remove slag or The crude oil a and the oil residue are obtained by centrifuging and removing the residue, and the crude oil b is recovered by pressing the oil residue, and the crude oil b is mixed with the crude oil a to obtain the j...

Embodiment 2

[0048] Select Jatropha jatropha fruits, remove the deteriorated Jatropha jatropha fruits and foreign matter, so that the impurity content is ≤2%; soak the selected Jatropha jatropha fruits in 0.5% dilute lye at 60°C for not less than 30 minutes, and then immerse them in cold water Rinse the jatropha fruit; then dry the peeled jatropha fruit and press it in an extruder at room temperature. The walnut kernels are divided into 18KG bags and put into the mold of the extruder. Separation of slices; pressing adopts segmented boosting method, the pressure of the oil outlet section with a pressure of 15MPa is boosted at a speed of 2MPa / min, and the pressure is released after the pressure rises to 40MPa; the squeezed jatropha oil is filtered to remove residue or The crude oil a and the oil residue are obtained by centrifuging and removing the residue, and the crude oil b is recovered by pressing the oil residue, and the crude oil b is mixed with the crude oil a to obtain the jatropha cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com