A kind of buffer solution for coating nucleic acid primer and preparation method of coating nucleic acid primer

A technology of buffer solution and buffer solution, which is applied in the direction of biochemical equipment and methods, microbial measurement/inspection, etc., can solve the problems of high material consumption cost, complex process technology, high reagent cost, etc., to reduce process complexity and process steps, cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

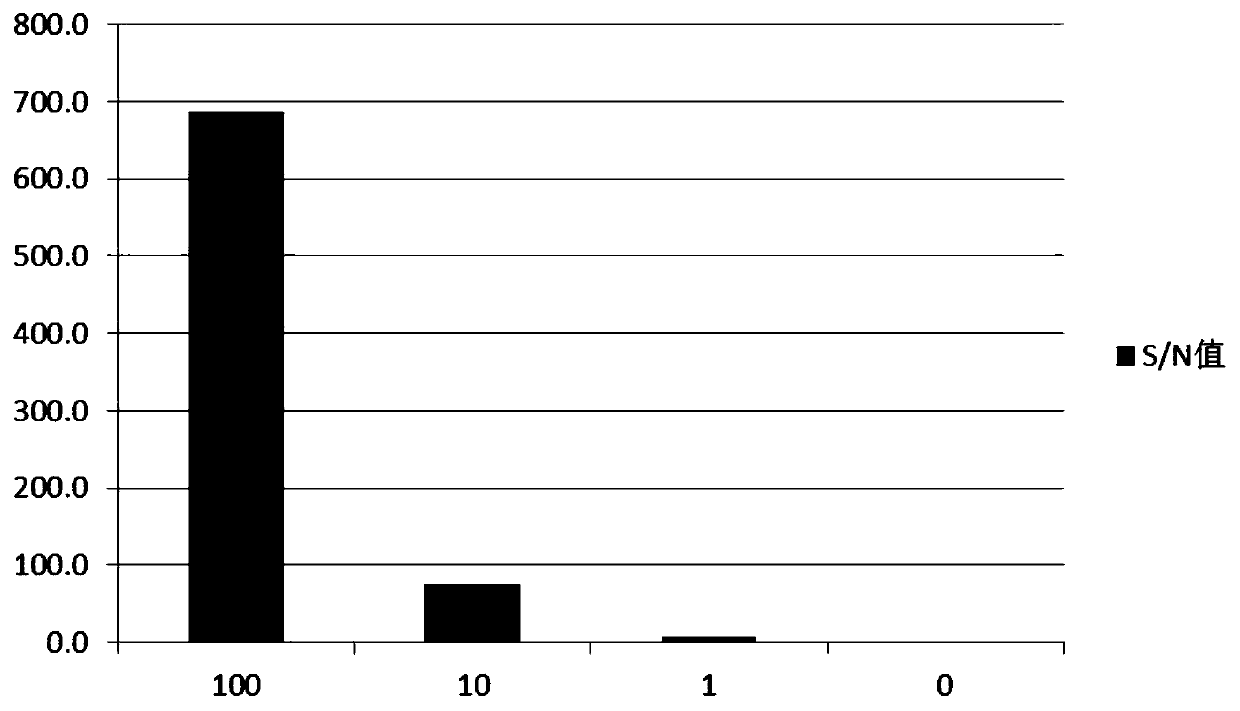

Image

Examples

preparation example Construction

[0039] The present invention also provides a method for preparing a coated nucleic acid primer, comprising the following steps:

[0040] A) dissolving the nucleic acid primer in the TE buffer solution to obtain a mixed solution;

[0041] After mixing disodium hydrogen phosphate, sodium dihydrogen phosphate, polylysine, sodium chloride, preservatives and water, a buffer solution is obtained;

[0042] B) After mixing the mixed solution obtained in the above steps and the buffer solution again, the coating mixed solution is obtained;

[0043] C) Put the coating mixture obtained in the above steps into a coating plate and perform coating to obtain coated nucleic acid primers.

[0044] In the preparation method of the present invention, the specific preferred scheme of the raw material, and the preferred numerical value of the number of parts added are consistent with the specific preferred scheme of the components in the aforementioned buffer solution, and the preferred numerical...

Embodiment 1

[0055] Application of coating buffer in the field of plate chemiluminescence;

[0056] Step 1: First design a nucleic acid sequence of a coating primer (5'-NH2-GAGCGGATATATGCTTAGGAAT-3'), synthesize the sequence and dissolve it in a TE buffer solution with a pH of 8.0, and dilute the primer to 3ug / mL;

[0057] Step 2: prepare coating buffer, according to the following concentration ratio, disodium hydrogen phosphate 5.6g / L, sodium dihydrogen phosphate 2.8g / L, sodium chloride 0.6g / L, sodium sulfate 17g / L , 28g / L poly-lysine, 0.06g / L preservative and deionized water, pay attention, add sodium phosphate buffer first, then add poly-lysine, and add easily soluble sodium sulfate after the solution is clarified and sodium chloride reagent, and magnetically stir at room temperature for 2 hours in the dark;

[0058] Step 3: Mix the primers dissolved in TE buffer and the prepared coating buffer in equal proportions to ensure that the final concentration of primers is 1.5 μg / mL;

[005...

Embodiment 2

[0083] Magnetic bead coating process:

[0084] 1. Add 500mg of amino (PVA) magnetic beads to a 1.5ml EP tube, wash 3 times with 1X pBS; add 0.1M MES for 3min;

[0085] 2. Adsorb the magnetic beads, pour off the MES solution, and add 1ml of the coating buffer solution provided by the present invention (according to the following concentration ratio, 5.5g / L disodium hydrogen phosphate, 3.0g / L sodium dihydrogen phosphate, 0.7 g / L sodium chloride, 18g / L sodium sulfate, 30g / L polylysine, 0.09g / L preservative and deionized water), then add primer 100pmol, and react for 2 to 3 hours;

[0086] 3. Add magnetic bead blocking agent (JSR, Cat#65293), end the reaction, adsorb the magnetic beads, and pour off the blocking agent;

[0087] 4. Wash three times with 1XPBS, dissolve the magnetic beads in 1X TE buffer, and set aside at 4°C.

[0088] So far, the coating process of the capture magnetic beads is completed.

[0089] Design a capture probe sequence as follows, see Table 5:

[0090...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com