Preparation method of transparent hydrophobic abrasion-resistant diamond-like film on transparent polymer surface

A technology of diamond thin film and transparent polymer, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of unreported and reduced transparency, and the method is simple and easy to be industrialized on a large scale The effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In this embodiment, the transparent substrate is a PET substrate. Prepare diamond-like carbon film on this PET substrate surface by linear ion beam method, specifically as follows:

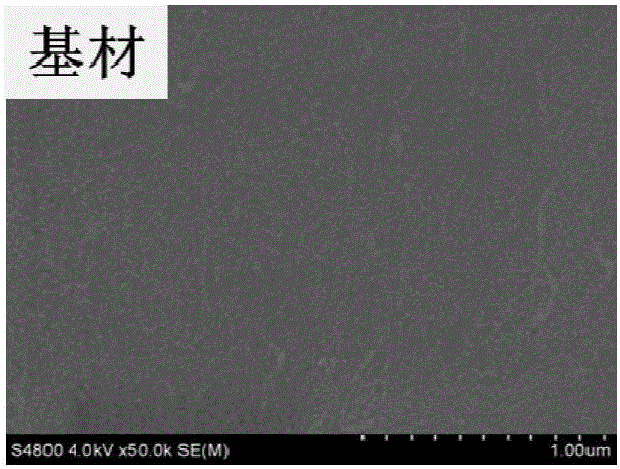

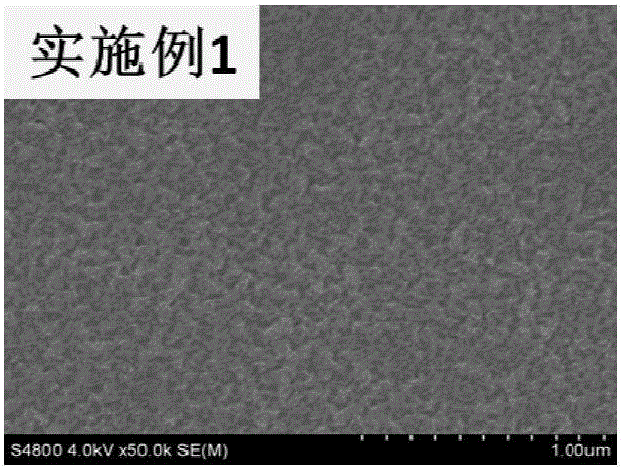

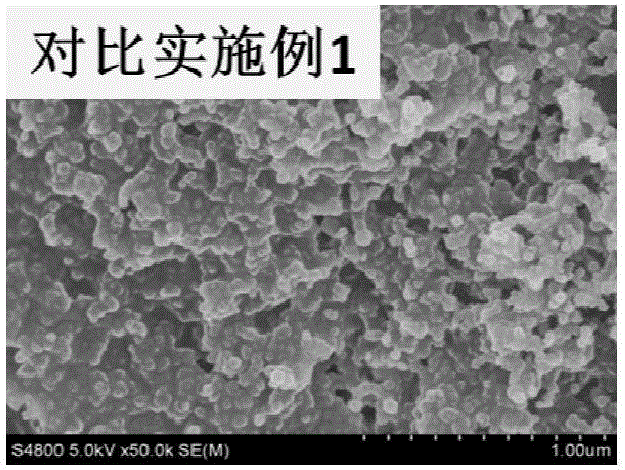

[0035] The surface morphology of the PET substrate before treatment is as follows: Figure 1A shown. First, the PET substrate was etched by Ar gas for 10 min, the linear ion beam current was 0.2A, and the Ar gas flow was 60 sccm; then, CH 4 and Ar gas, CH 4 The flow ratio with Ar gas is 15:30, CH 4 The flow rate is 15sccm, the linear ion beam current is 0.2A, and the deposition time is 20min, and a diamond-like carbon film is obtained, and its surface morphology is as follows: Figure 1B shown.

[0036] The naked eye transmittance of the PET substrate to visible light before and after coating is as follows: figure 2 As shown in , after testing, its light transmittance change curve for visible light is as follows image 3 shown. That is, compared with the PET substrate without deposi...

Embodiment 2

[0046] In the present embodiment, the transparent substrate is the same PET substrate as in Example 1, and a diamond-like carbon film is prepared on the surface of the PET substrate by a linear ion beam method, as follows:

[0047] First, the PET substrate was etched by Ar gas for 15 min, the linear ion beam current was 0.2A, and the Ar gas flow was 40 sccm; then, CH 4 and Ar gas, CH 4 The flow ratio with Ar gas is 15:45, CH 4 The flow rate is 15 sccm, the linear ion beam current is 0.1A, and the deposition time is 10 min to obtain a diamond-like carbon film.

[0048] After testing, the change curve of the light transmittance of the PET substrate to visible light before and after coating is as follows: image 3 shown. That is, compared with the PET substrate without depositing the diamond-like carbon film, after depositing the diamond-like carbon film on the surface of the PET substrate, it still maintains the high transmittance of the substrate itself for visible light; fo...

Embodiment 3

[0051] In the present embodiment, the transparent substrate is the same PET substrate as in Example 1, and a diamond-like carbon film is prepared on the surface of the PET substrate by a linear ion beam method, as follows:

[0052] First, pass O 2 Gas etched the PET substrate for 5min, the linear ion beam current was 0.15A, O 2 The air flow is 50sccm; then, pass into C 2 h 2 and Ar gas, C 2 h 2 The flow ratio with Ar gas is 6:60, C 2 h 2 The flow rate is 6 sccm, the linear ion beam current is 0.15A, and the deposition time is 30 min to obtain a diamond-like carbon film.

[0053] After testing, the change curve of the light transmittance of the PET substrate to visible light before and after coating is as follows: image 3 shown. That is to say, compared with the PET substrate without depositing the diamond-like carbon film, after depositing the diamond-like carbon film on the surface of the PET substrate, it maintains the high transmittance of the substrate itself for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com