Breathable synthetic leather and manufacture method thereof

A synthetic leather, wet-laid technology, applied in textiles and papermaking, etc., can solve the problems that cannot replace the usage of natural leather products, the hot air is discharged from human skin, and the air permeability is not as good as that of natural leather, etc., and achieves excellent mechanical strength, smoothness and plumpness. The effect of hand feeling and good breathability and moisture permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

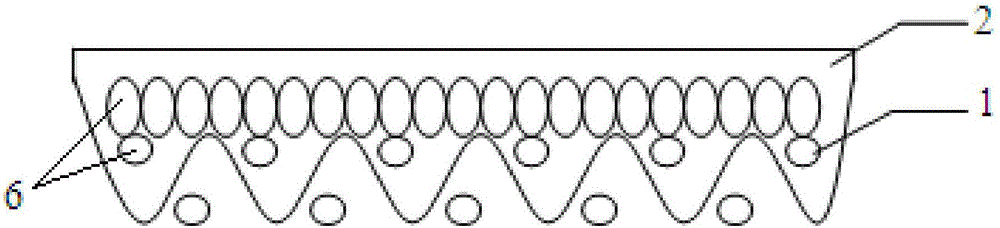

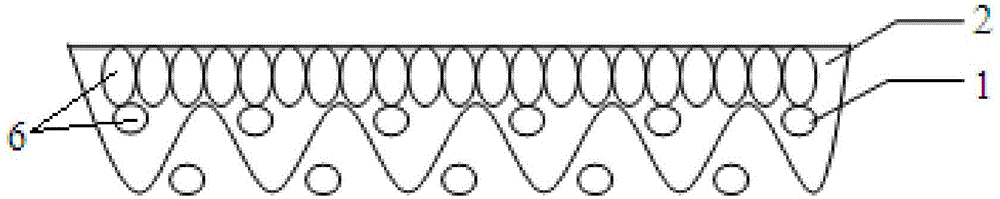

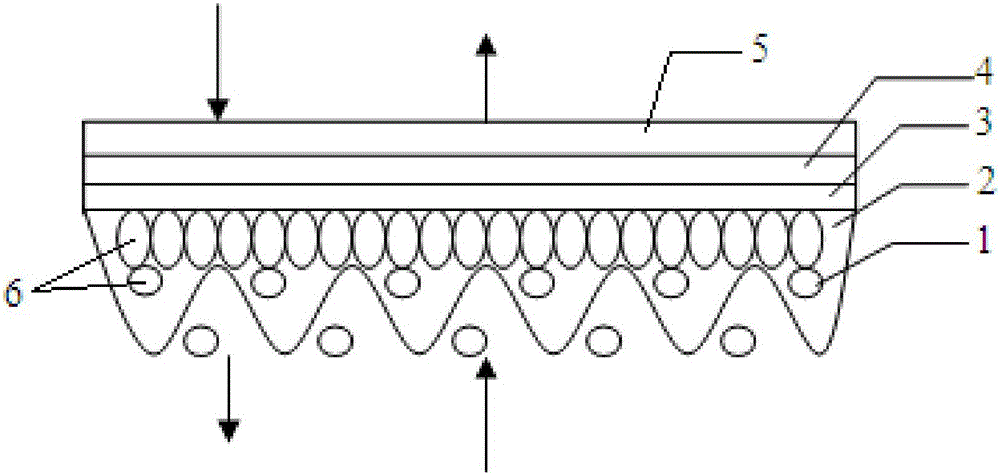

[0037] Such as Figure 1 to 3 As shown, this embodiment provides a breathable synthetic leather. From bottom to top, the breathable synthetic leather structure includes a base fabric layer 1, a wet PU layer 2, a PU breathable adhesion layer 3, and a dry breathable PU texture layer 4. And the breathable treatment layer 5, the base fabric layer 1 and the wet PU layer 2 are each provided with several breathable micropores 6;

[0038] The dry-process breathable PU texture layer 4 includes the following components:

[0039]

[0040] The PU air-permeable binding layer 3 includes the following components:

[0041]

[0042] The particle size of wood powder is 5μm-50μm. Wood powder can not only reduce product costs, but also play a role in the solidification process. The high temperature expansion and normal temperature shrinkage of wood powder during the drying process of resin molding (80℃-50℃) and foaming agent The styling effect of the polyurethane resin makes the polyurethane resin pr...

Embodiment 2

[0060] The difference from Example 1 is:

[0061] The dry-process breathable PU texture layer 4 includes the following components:

[0062]

[0063] The PU air-permeable binding layer 3 includes the following components:

[0064]

[0065] The foaming agent is oleic acid monoethanolamide, the penetrating agent is fatty alcohol polyoxyethylene ether, the wetting agent is sodium dodecylbenzene sulfonate, and the curing agent is nanometer montmorillonite.

[0066] The thickness of the base fabric layer 1 is 0.05mm-0.5mm, the thickness of the wet PU layer 2 is 0.15mm, the thickness of the PU breathable adhesion layer 3 is 0.12mm, the thickness of the breathable treatment layer 5 is 0.12mm, and the thickness of the dry breathable PU The thickness of the texture layer 4 is 0.2 mm.

[0067] The negative ion powder is tourmaline particles with a particle size of 5μm-50μm.

[0068] The preparation method includes the following steps:

[0069] The first step is to coat the wet PU layer on the base ...

Embodiment 3

[0075] The difference from Example 1 is:

[0076] The dry-process breathable PU texture layer 4 includes the following components:

[0077]

[0078] The PU breathable adhesive layer includes the following components:

[0079]

[0080]

[0081] The foaming agent is coconut oil acid diethanolamide, the penetrating agent is dioctyl sulfosuccinate sodium salt, the wetting agent is dodecylbenzene sulfonic acid, and the curing agent is hydrophilic aliphatic polyisocyanate.

[0082] The thickness of the base fabric layer 2 is 0.4mm, the thickness of the wet PU layer 2 is 0.15mm, the thickness of the PU breathable adhesion layer 3 is 0.15mm, the thickness of the breathable treatment layer 5 is 0.15mm, and the dry method breathable PU pattern layer 4 The thickness is 0.15mm.

[0083] Anion powder is seabed ore particles with a particle size of 5μm-50μm.

[0084] The preparation method includes the following steps:

[0085] The first step is to coat the wet PU layer on the base fabric. 2: The base...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com