Reflective type high-speed camera shooting schlieren system applied to constant volume combustion bomb and capable of correcting chromatic aberration

A constant-volume incendiary bomb and high-speed camera technology, applied in optical components, optics, instruments, etc., can solve the problems of unstable light effects, affecting experimental accuracy, and high power consumption, etc., to achieve convenient and arbitrary movement, good optical fiber flexibility, The effect of not getting hot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

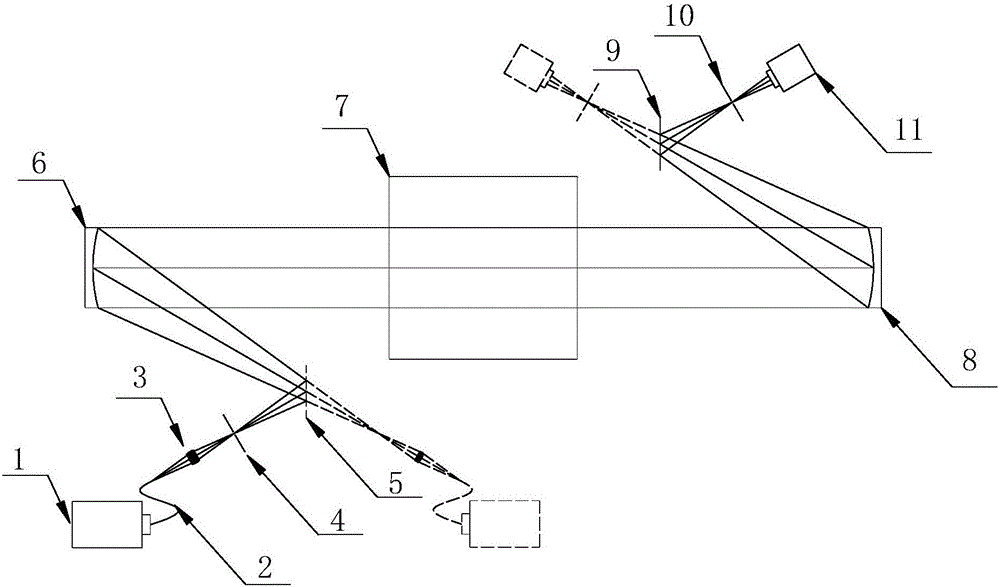

[0021] The reflective constant volume incendiary bomb high-speed camera schlieren system shown in the figure can correct chromatic aberration, including light source 1, optical fiber 2, condenser lens group 3, slit device 4, first reflector 5, collimator Mirror 6, constant volume incendiary bomb 7, schlieren mirror 8, second reflector 9, knife edge 10 and high-speed camera 11; light source 1 is an LED-light source, the optical input end of optical fiber 2 is connected with light source 1, and the optical output of optical fiber 2 The end is connected with the condenser lens group 3, and the focus of the condenser lens group 3 and the focus of the collimator mirror 6 after being reflected by the first reflector 5 coincide at the slit device 4, so that the size of the light source can be adjusted by adjusting the aperture size of the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com