GaN-based white-light LED and preparation method

A white light and blue light technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of high cost and complex methods of generating white light, and achieve the effects of high conversion efficiency, low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

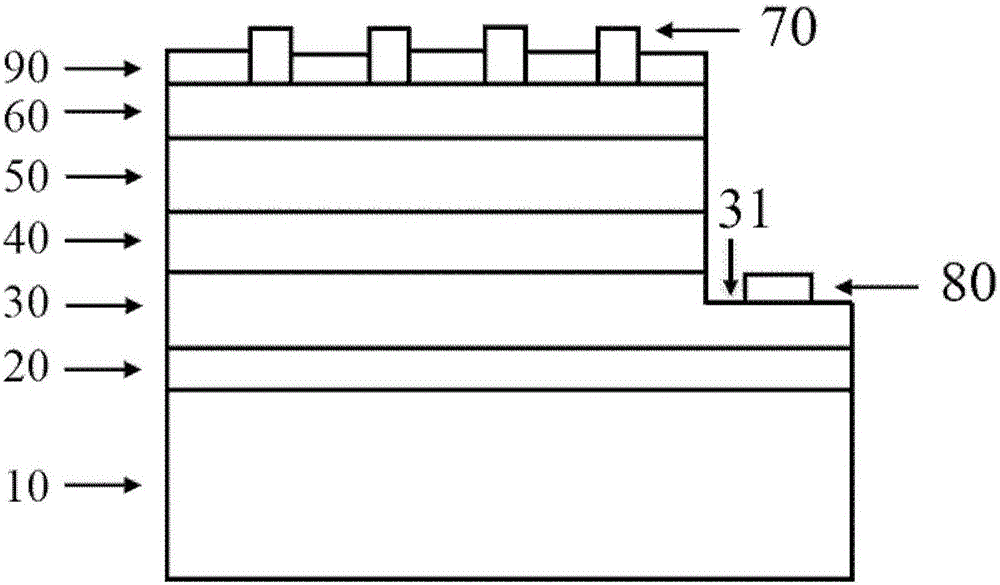

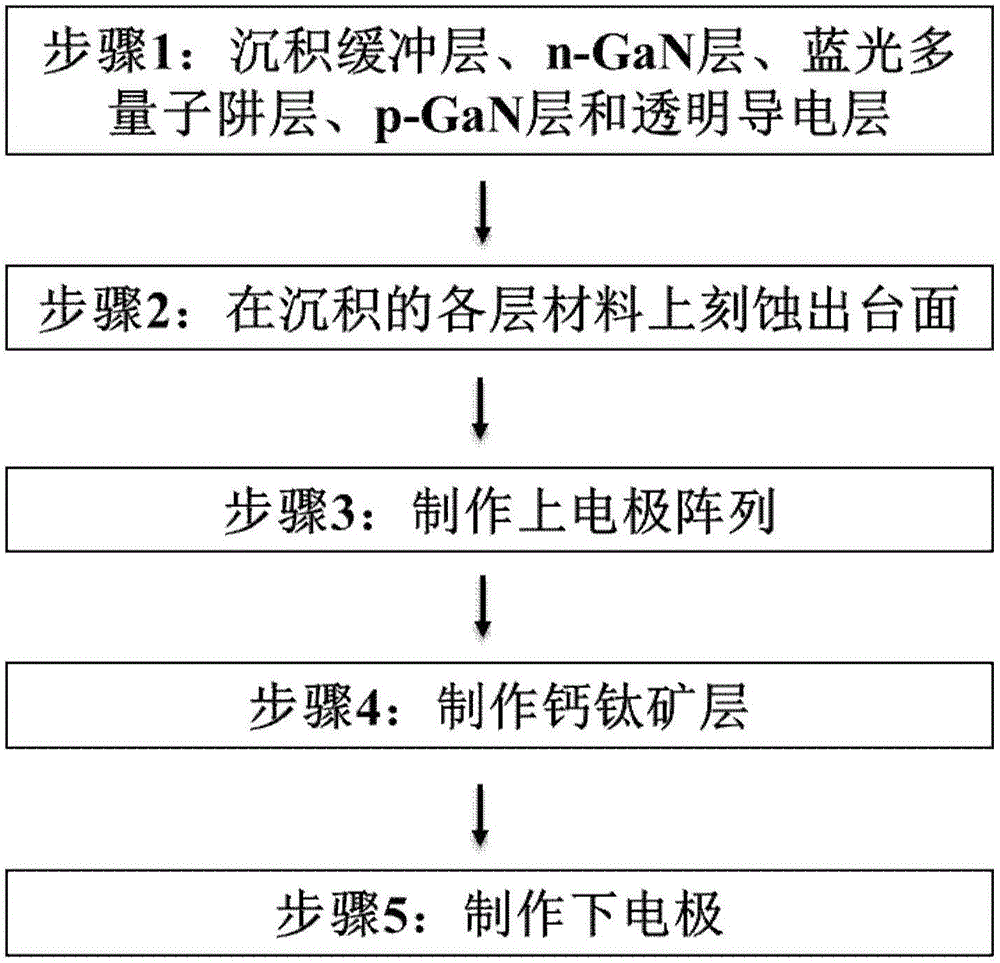

[0042] see figure 2 and refer to figure 1 As shown, the present invention also provides a method for preparing a GaN-based white light LED, comprising the following steps:

[0043]Step 1: sequentially fabricate a buffer layer 20, an n-GaN layer 30, a blue light multi-quantum well layer 40, a p-GaN layer 50 and a transparent conductive layer 60 on a substrate 10 by means of MOCVD, the substrate 10 The material is sapphire, SiC or Si, the material of the blue multi-quantum well layer 40 is at least two of InGaN, InAlN, AlGaN, AlInGaN or InGaAlP, and the material of the transparent conductive layer 60 is ITO, FTO or silver nanowire ;

[0044] Step 2: Etching downward from the side above the transparent conductive layer 60, the etching depth reaches into the n-GaN layer 30, and forming a mesa 31 on one side of the n-GaN layer 30;

[0045] Step 3: making an upper electrode array 70 on the transparent conductive layer 60;

[0046] Step 4: Make a perovskite layer 90 on the top o...

Embodiment 1

[0049] A low-temperature GaN buffer layer was deposited on the sapphire substrate by metal-organic chemical vapor deposition (MOCVD). An approximately 2 μm thick n-GaN layer is deposited on the GaN buffer layer. A blue light multiple quantum well layer is deposited on the n-GaN layer. A layer of about 2 μm-GaN is deposited on the blue MQW layer. Perform photolithography and etching to etch part of the area down to the n-GaN layer. A transparent conductive layer is deposited on the unetched p-GaN layer with a thickness of 200-500 nm by electron beam evaporation. A Ti / Au metal electrode array was deposited on the transparent conductive layer with EB. Ti / Au metal electrodes are deposited on the n-GaN layer exposed after etching. 0.9 mol of PbBr2, 0.1 mol of PbI2 and 1 mol of CH 3 NH 3 Br mixed, dissolved in 2ml DMF, fully dissolved and filtered. The perovskite layer is deposited on the transparent conductive layer by gas-assisted spin coating, the speed of the homogenizer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com