Silsesquioxane having hot melt extrusion forming capability, highly transparent and highly heat-resistant plastic transparent substrate using same, and method of manufacturing same

A technology of silsesquioxane and transparent substrates, which is applied in coatings and other directions, can solve the problems of small improvement, difficult application of substrates, and difficult application of plastic transparent substrates, etc., and achieve good light transmittance and less thermal deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

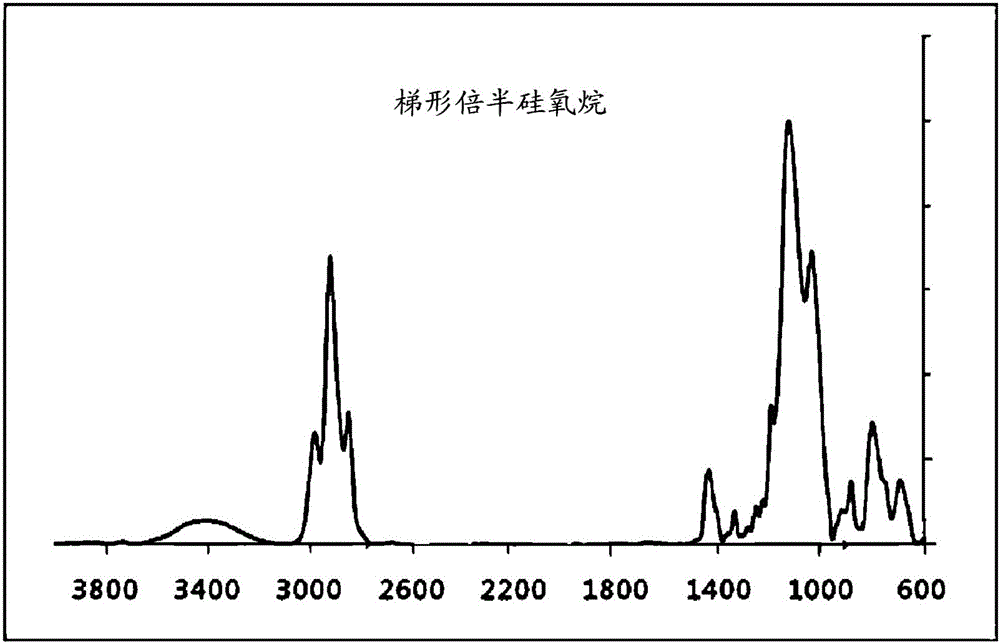

[0093] Synthesis Example 1: Synthesis of Ladder Silsesquioxane Compounds

[0094] In a dry flask equipped with a cooling tube and a stirrer, add 15 parts by weight of distilled water, 85 parts by weight of methanol (purity 99.86%), 1 part by weight of potassium carbonate (purity 98%), epoxycyclohexylethyltrimethoxysilane (Shin-etsu, trade name KBM-303) 50 parts by weight, γ-methacryloxypropyltrimethoxysilane (DOW CORNING company, trade name DOW CORNING (R) Z-6030SILANE) 30 parts by weight and benzene 20 parts by weight of trimethoxysilane (DOW CORNING company, trade name DOW CORNING (R) Z-6124SILANE), slowly stirred for 8 hours under nitrogen atmosphere, then dropped into dichloromethane (purity 99.5%, Toyo Steel Chemical) 100 parts by weight, and further stirred for 2 hours.

[0095] The stirred liquid was washed several times with distilled water and classified to remove impurities, finally washed with methanol, and then the washed liquid was vacuum-dried at room temperatur...

Synthetic example 2

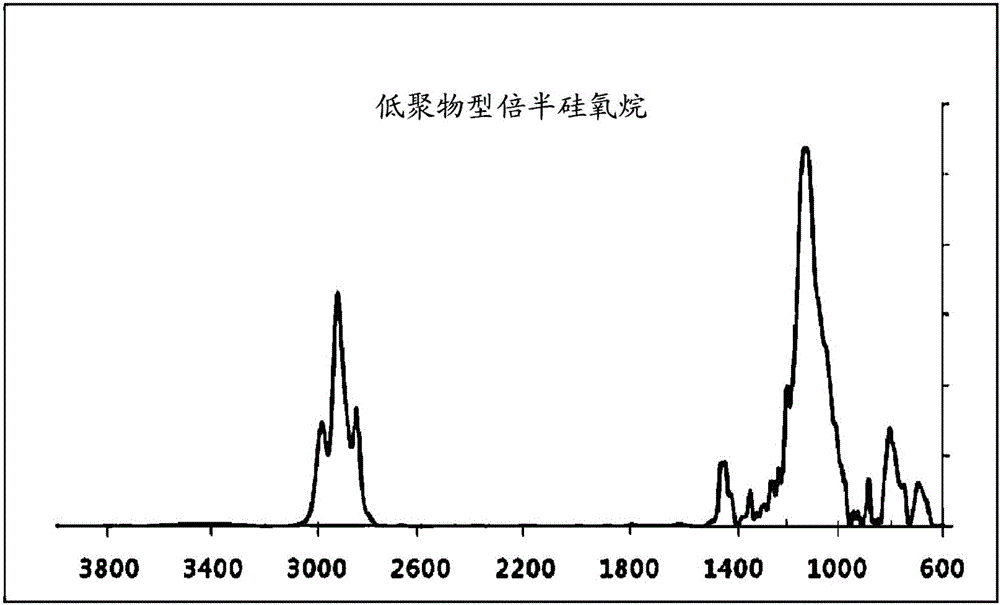

[0096] Synthesis example 2: the synthesis of clathrate silsesquioxane compound

[0097]*In a dry flask equipped with a cooling tube and a stirrer, add 10 parts by weight of distilled water, 85 parts by weight of methanol (purity 99.86%), 5 parts by weight of tetramethylammonium hydroxide (purity 25%), epoxycyclohexylethyl ether 50 parts by weight of propyltrimethoxysilane (Shin-etsu, trade name KBM-303), γ-methacryloxypropyl trimethoxysilane (DOW CORNING company, trade name DOW CORNING (R) Z-6030SILANE) 30 parts by weight and 20 parts by weight of methyltrimethoxysilane (DOW CORNING company, trade name DOW CORNING (R) Z-6300SILANE), slowly stirred for 6 hours under nitrogen atmosphere, then dropped into dichloromethane (purity 99.5%, Toyo Iron and Steel Chemicals) 200 parts by weight, and further stirred for 24 hours. Thereafter, a liquid clathrate silsesquioxane compound was obtained by the same method as in Synthesis Example 1 above.

Embodiment 1

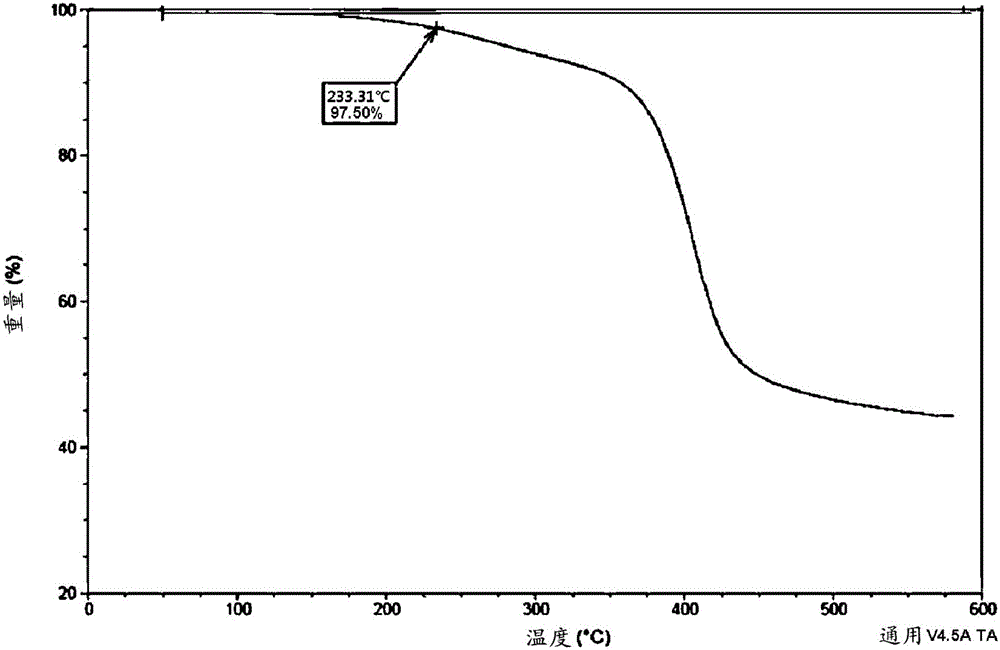

[0100] Embodiment 1: the manufacture of the first substrate

[0101] The trapezoidal silsesquioxane compound synthesized in Synthesis Example 1 above was put into a mold, pressurized at 200°C for hot-melt molding, cooled, and solidified completely at 100°C for 2 hours and at 140°C for 1 Hours and 1 hour at 180° C. were cured step by step to finally produce a plastic transparent substrate with a thickness of 200 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com