A kind of preparation method of go/sb-biobr composite photocatalyst

A technology of photocatalyst and composite light, applied in chemical instruments and methods, light water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of reducing the probability of recombination of electrons and holes, located in the ultraviolet region, and solar energy utilization Low efficiency and other problems, to achieve the effect of favorable degradation, easy availability of raw materials, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

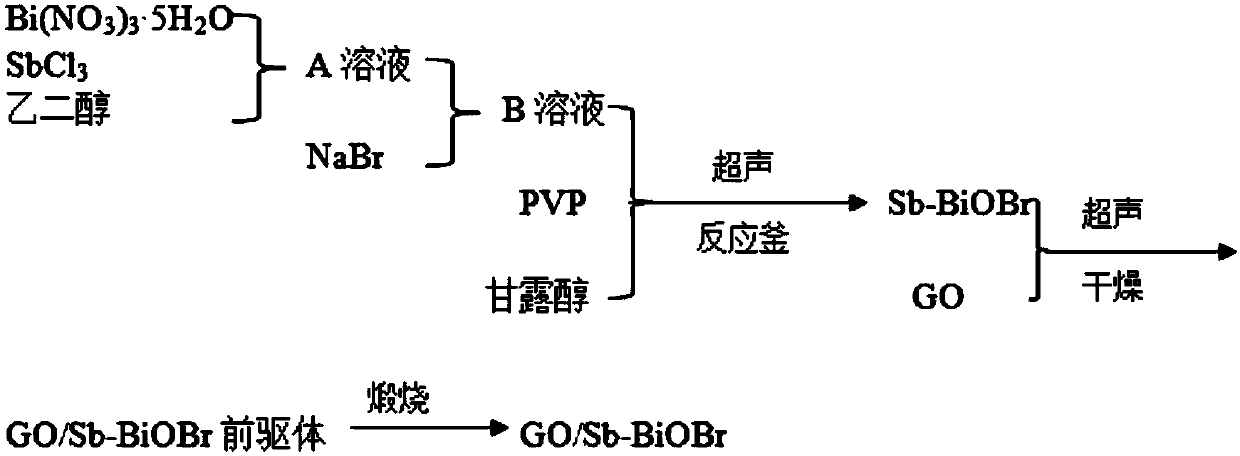

[0028] A kind of preparation method of GO / Sb-BiOBr composite photocatalyst, concrete steps are as follows:

[0029] (1) Preparation of Sb-BiOBr photocatalyst

[0030] Weigh 2.4254gBi(NO 3 ) 3` 5H 2 O and 0.0114gSbCl 3 Dissolve in 30mL of ethylene glycol, then weigh 0.5145g NaBr and slowly add it to the above solution, ultrasonically oscillate for 10min, then add 0.20g of polyvinylpyrrolidone and 0.0020g of mannitol, stir well, then ultrasonically oscillate for 30min again, Then transfer the shaken solution to a 50mL polytetrafluoroethylene autoclave, react at 150°C for 6h, wash with deionized water several times to remove excess ions and other impurities in the precipitate, and wash with absolute ethanol several times In order to remove excess organic matter, after washing, it was placed in a blast drying oven at 70° C. for 8 hours to obtain a 1% atm Sb-BiOBr photocatalyst.

[0031] (2) Preparation of GO (graphene oxide)

[0032] Prepare GO by airtight oxidation method, ...

Embodiment 2

[0036] A preparation method of a GO / Sb-BiOBr composite photocatalyst, the specific steps are as follows:

[0037] (1) Weigh 2.4254gBi (NO 3 ) 3` 5H 2 O and 0.0342gSbCl 3 Dissolve in 30mL of ethylene glycol, then weigh 0.5145g of NaBr and slowly add it to the above solution, ultrasonically vibrate for 10min and then add 0.20g of polyvinylpyrrolidone and 0.0020g of mannitol to it, stir evenly and then ultrasonically vibrate again for 30min. Then transfer the shaken solution to a 50mL polytetrafluoroethylene autoclave, react at 150°C for 6 hours, wash with deionized water for several times to remove excess ions and other impurities in the precipitate, and wash with absolute ethanol for several times In order to remove excess organic matter, after washing, it was placed in a blast drying oven at 70° C. for drying for 8 h to obtain a 3% atm Sb-BiOBr photocatalyst.

[0038] (2) step (2) with embodiment 1;

[0039] (3) According to the mass ratio of Sb-BiOBr to GO of 100:0.5, we...

Embodiment 3

[0041] A preparation method of a GO / Sb-BiOBr composite photocatalyst, the specific steps are as follows:

[0042] (1) Weigh 2.4254gBi (NO 3 ) 3` 5H 2 O and 0.0570gSbCl 3 Dissolve in 30mL of ethylene glycol, then weigh 0.5145g of NaBr and slowly add it to the above solution, ultrasonically vibrate for 10min and then add 0.20g of polyvinylpyrrolidone and 0.0020g of mannitol to it, stir evenly and then ultrasonically vibrate again for 30min. Then transfer the shaken solution to a 50mL polytetrafluoroethylene autoclave, react at 150°C for 6 hours, wash with deionized water for several times to remove excess ions and other impurities in the precipitate, and wash with absolute ethanol for several times In order to remove excess organic matter, after washing, it was placed in a blast drying oven at 70° C. to dry for 8 h to obtain a 5% atm Sb-BiOBr photocatalyst.

[0043] (2) step (2) with embodiment 1;

[0044] (3) According to the mass ratio of Sb-BiOBr to GO of 100:0.5, weigh ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com