Preparation method of copper-based super-hydrophobic corrosion and scale preventing film for chloride ion corrosion and calcium carbonate scale

A technology for chloride ion corrosion and calcium carbonate scaling, which is applied to devices for coating liquid on surfaces, pretreatment surfaces, coatings, etc. It can solve complex processes, expensive equipment or hydrophobic agents, and no functional requirements for corrosion resistance. and other problems, to achieve the effect of simple preparation equipment, favorable for popularization and application, good corrosion resistance and anti-scaling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The preparation method of the copper-based super-hydrophobic anti-corrosion anti-scaling film for chloride ion corrosion and calcium carbonate scale of the present invention, it comprises the following steps:

[0055] (1) The copper sheet is polished and pretreated by ultrasonic cleaning to remove oxides and other dirt on the surface of the copper sheet, and make the surface of the copper sheet smooth;

[0056] (2) putting the pretreated copper sheet into concentrated ammonia water with a mass percentage concentration of 25%-28% for ultrasonic-assisted etching for 0.5-1 hour, and then calcining to form a uniform roughness on the surface of the copper sheet;

[0057] (3) Soak the copper sheet with uniform roughness in ethanol solution of octadecanoic acid with a temperature of 25°C-55°C and a concentration of 0.01mol / L-0.05mol / L for 4-6 days, then take it out and put it in Heat treatment in an oven to form a super-hydrophobic surface on the surface of the copper sheet. ...

Embodiment 1

[0065] Roughly polish the 2.5cm×3cm×0.5cm copper sheet with a coarse grinding wheel to remove surface oxides and other dirt, then apply green polishing paste, and use a wool wheel for fine polishing to make the surface smooth and mirror-like. Then use detergent, ethanol, and distilled water to perform ultrasonic cleaning for 10 minutes, and then air dry naturally.

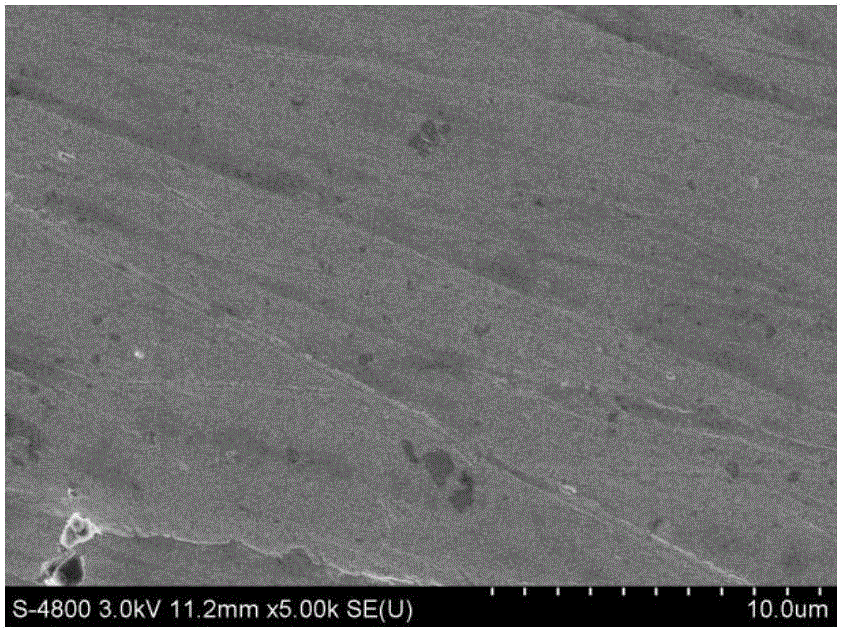

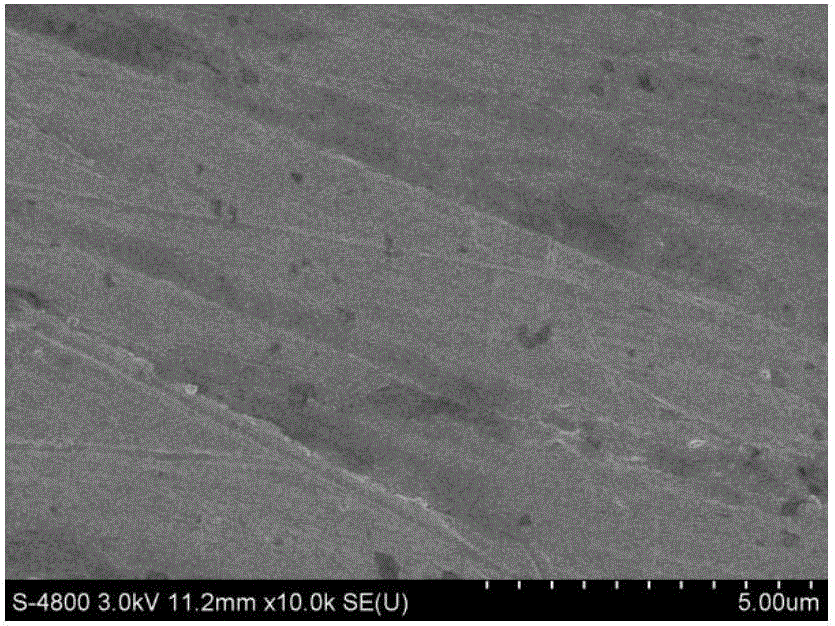

[0066] Put the polished and cleaned pretreated copper sheet into 28% concentrated ammonia water for ultrasonic etching for 60 minutes, and then calcined at 200° C. for 60 minutes to form primary roughness.

[0067] Rinse the copper sheet with primary roughness with distilled water and then immerse it in 0.01mol / L ethanol solution of octadecanoic acid for immersion reaction. The immersion time is 6 days and the immersion temperature is room temperature 25°C.

[0068] After the immersion reaction, the samples were taken out and put into an oven for heat treatment at 80°C for 2 hours.

Embodiment 2

[0070] Roughly polish the 2.5cm×3cm×0.5cm copper sheet with a coarse grinding wheel to remove surface oxides and other dirt, then apply green polishing paste, and use a wool wheel for fine polishing to make the surface smooth and mirror-like. Then use detergent, ethanol, and distilled water to perform ultrasonic cleaning for 10 minutes, and then air dry naturally.

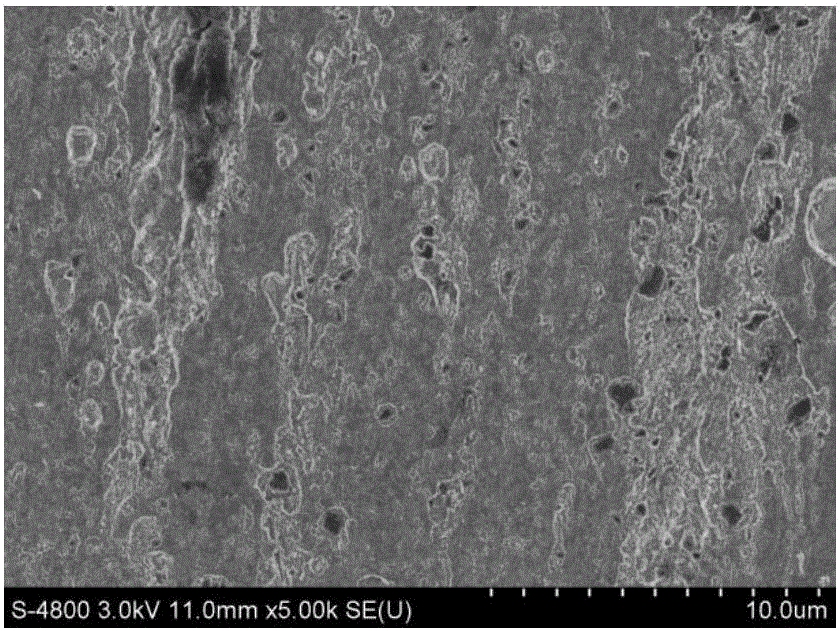

[0071] Put the polished and cleaned pretreated copper sheet into 27% concentrated ammonia water for ultrasonic etching for 60 minutes, and calcined at 350° C. for 30 minutes to form primary roughness.

[0072] Rinse the copper sheet with primary roughness with distilled water and then immerse it in 0.02mol / L ethanol solution of octadecanoic acid for immersion reaction. The immersion time is 5 days and the immersion temperature is 45°C.

[0073] After the immersion reaction, the samples were taken out and put into an oven for heat treatment at 80°C for 1 hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com