Aramid paper honeycomb sandwich composite structure with high strength and light weight

A composite structure, aramid paper technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesive types, etc., can solve the problem of increasing the weight of the structure, to improve the external bearing capacity, weight The effect of light weight and high peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

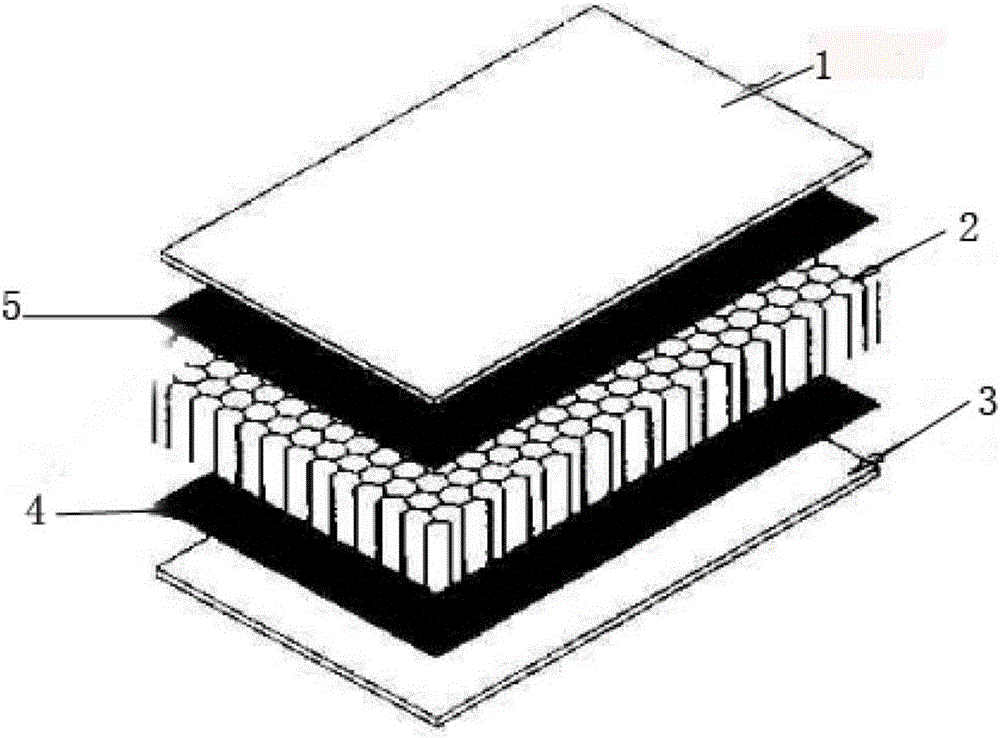

[0031]In the high-strength and light-weight aramid paper honeycomb sandwich composite structure of this embodiment, the composite board includes a lower skin 3, a lower hot-melt adhesive film 4, and an aramid paper honeycomb core stacked sequentially from bottom to top. 2. The upper hot-melt adhesive film 5 and the upper skin 1 are composited. The upper skin 1 and the lower skin 3 are glass cloth prepregs formed by impregnating glass cloth with a resin composition. The aramid paper honeycomb The cell of the core is a regular hexagon in section, the radius of the circumscribed circle of the regular hexagon is 50mm, the side length of the cell is 3mm, and the aperture ratio is 1; the paper thickness of the aramid paper honeycomb core is 0.03mm, and the density is 30kg / m 3 ; The resin composition includes by weight: 10 parts of diphenylmethane bismaleimide, 3 parts of o-diallyl bisphenol A, 5 parts of diallyl bisphenol A, 5 parts of polyethersulfone, polyether 6 parts of ketone, ...

Embodiment 2

[0040] In the high-strength and light-weight aramid paper honeycomb sandwich composite structure of this embodiment, the composite board includes a lower skin 3, a lower hot-melt adhesive film 4, and an aramid paper honeycomb core stacked sequentially from bottom to top. 2. The upper hot-melt adhesive film 5 and the upper skin 1 are composited. The upper skin 1 and the lower skin 3 are glass cloth prepregs formed by impregnating glass cloth with a resin composition. The aramid paper honeycomb The cell of the core is a regular hexagon in section, the radius of the circumscribed circle of the regular hexagon is 100mm, the side length of the cell is 6mm, and the aperture ratio is 1; the paper thickness of the aramid paper honeycomb core is 0.06mm, and the density is 35kg / m 3 ; The resin composition comprises by weight: 20 parts of diphenylmethane bismaleimide, 8 parts of o-diallyl bisphenol A, 15 parts of diallyl bisphenol A, 10 parts of polyethersulfone, polyether 12 parts of ke...

Embodiment 3

[0049] In the high-strength and light-weight aramid paper honeycomb sandwich composite structure of this embodiment, the composite board includes a lower skin 3, a lower hot-melt adhesive film 4, and an aramid paper honeycomb core stacked sequentially from bottom to top. 2. The upper hot-melt adhesive film 5 and the upper skin 1 are composited. The upper skin 1 and the lower skin 3 are glass cloth prepregs formed by impregnating glass cloth with a resin composition. The aramid paper honeycomb The cell of the core is a regular hexagon in section, the radius of the circumscribed circle of the regular hexagon is 50mm, the side length of the cell is 6mm, and the aperture ratio is 1; the paper thickness of the aramid paper honeycomb core is 0.03mm, and the density is 35kg / m 3 ; The resin composition comprises by weight: 10 parts of diphenylmethane bismaleimide phenol, 8 parts of o-diallyl bisphenol A, 5 parts of diallyl bisphenol A, 10 parts of polyethersulfone, polyether 6 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com