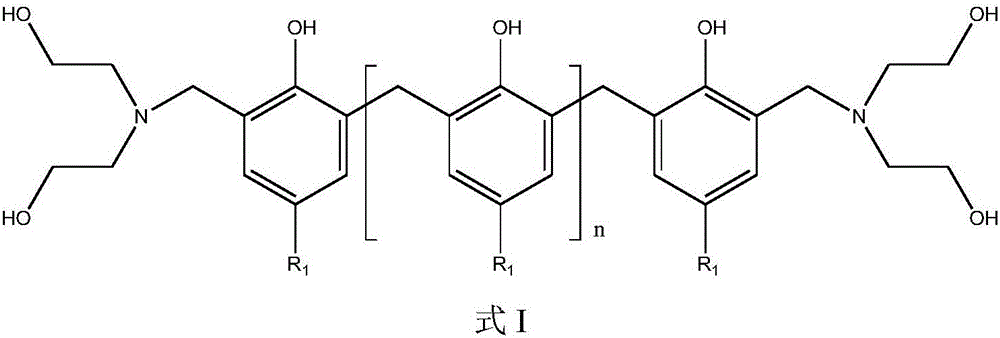

Polyether demulsifying agent based on hydramine-modified phenolic resin and synthesizing method thereof

A technology of polyether demulsifier and phenolic resin, applied in the direction of dehydration/demulsification by chemical methods, can solve the problems of poor dehydration effect of polyether demulsifier, and achieve the effect of wide application range and good dehydration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The synthesis of polyether demulsifier DE-01 based on diethanolamine modified p-tert-butylphenolic resin, the mass ratio of initiator: propylene oxide: ethylene oxide is 1:29:10, the synthesis steps are as follows:

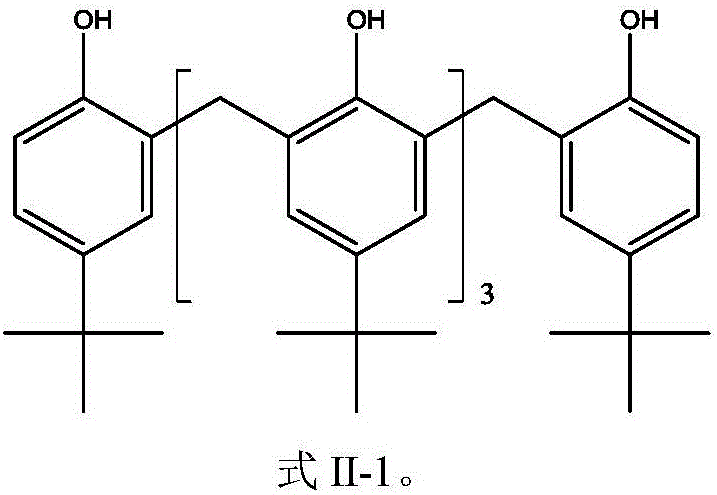

[0019] (1) Add 150.3g of p-tert-butylphenol, 64.8g of formaldehyde and 0.6g of oxalic acid into a four-necked flask equipped with a stirrer, a thermometer and a condenser, stir evenly at 45°C, and then heat up to 75-80°C for reaction Heating was stopped after 4h. The crude product was dehydrated under reduced pressure with a rotary evaporator, and finally dehydrated under reduced pressure at 120-130°C and -0.095MPa for 2 hours to obtain p-tert-butylphenol-formaldehyde resin, whose structure is shown in formula II-1.

[0020]

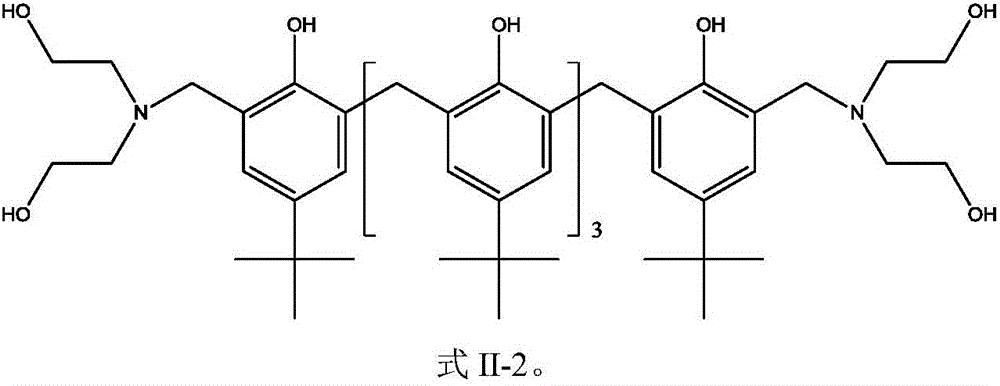

[0021] (2) Get p-tert-butylphenol-formaldehyde resin 159.7g, diethanolamine 46.3g and 30% ZnCl 2 8 mL of the solution was placed in a three-necked flask and stirred evenly, and 40.5 g of formaldehyde was added dropwise at 50°C. Af...

Embodiment 2

[0026] The synthesis of polyether demulsifier DE-02 based on diethanolamine modified p-tert-butylphenolic resin, the mass ratio of initiator: propylene oxide: ethylene oxide is 1:59:24, and the synthesis steps are as follows:

[0027] Take 100 g of polyether oil head in step (3) of Example 1 and 2.6 g of potassium hydroxide in a 2L high-temperature and high-pressure magnetic stirrer, start the stirring and heat up, replace with nitrogen 3 times and dehydrate under reduced pressure for 30 minutes, and wait until the temperature rises to 500g of propylene oxide is introduced at around 120°C, the reaction temperature is controlled at 120-140°C, the pressure is lower than 0.5MPa, and the reaction is kept for 1h after the reaction reaches negative pressure. When the temperature drops to about 110°C, 240g of ethylene oxide is introduced, the reaction temperature is controlled at 110-130°C, and the pressure is lower than 0.5MPa. After the temperature reaches negative pressure, keep wa...

Embodiment 3

[0029] The synthesis of polyether demulsifier DE-03 based on diethanolamine modified p-tert-butylphenolic resin, the mass ratio of initiator: propylene oxide: ethylene oxide is 1:99:50, the synthesis steps are as follows:

[0030] Take 100 g of polyether oil head and 4.5 g of potassium hydroxide in step (3) of Example 1 in a 2L high-temperature and high-pressure magnetic stirrer, start the stirring and heat up, replace with nitrogen 3 times and vacuum dehydrate for 30 minutes, and wait until the temperature rises to 120 900g of propylene oxide is introduced at about ℃, the reaction temperature is controlled at 120-140℃, the pressure is lower than 0.5MPa, and the reaction is kept under negative pressure for 1h. When the temperature drops to about 110°C, 500g of ethylene oxide is introduced, the reaction temperature is controlled at 110-130°C, and the pressure is lower than 0.5MPa. After the temperature reaches negative pressure, keep warm for 1 hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com