A method for plasma modification of polytetrafluoroethylene microporous membrane

A polytetrafluoroethylene and plasma technology, applied in the direction of coating, can solve the problems of reduced mechanical strength of microporous membrane, maintaining PTFE microporous membrane, poor modification effect, etc., to improve hydrophilicity and short cycle. , the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Pretreatment of PTFE microporous membrane:

[0025] Flatten the PTFE microporous membrane with two A4 papers, place it under a flat paper cutter, and cut into several 5×5cm PTFE microporous membranes, and immerse the cut PTFE microporous membranes in acetone solution. Soak in a fume hood for 12-24h, then soak in 80%-98% ethanol solution for 3-12h, change the ethanol solution several times to remove acetone, then wash with deionized water several times to remove the ethanol, and finally put it in In a vacuum drying oven, dry at 30-70°C for 10-24 hours, cool the dried PTFE microporous membrane to room temperature, and then fix the microporous membrane on a glass plate for the next plasma modification.

Embodiment 2

[0027] The pretreatment method of the PTFE microporous membrane is as in Example 1.

[0028] Plasma treatment:

[0029] First put the pretreated PTFE microporous membrane in the plasma high vacuum preparation chamber, in the N 2 +CH 4 Under mixed gas, adjust the plasma treatment distance to 40cm, select the treatment time 100s, and the gas flow rate to 20cm 3 / s, the intake ratio is 1:1, that is, the gas flow rates of methane and nitrogen are both 10cm 3 / s, control the plasma power, the power is respectively selected 20w, 40w, 60w, 80w, 100w.

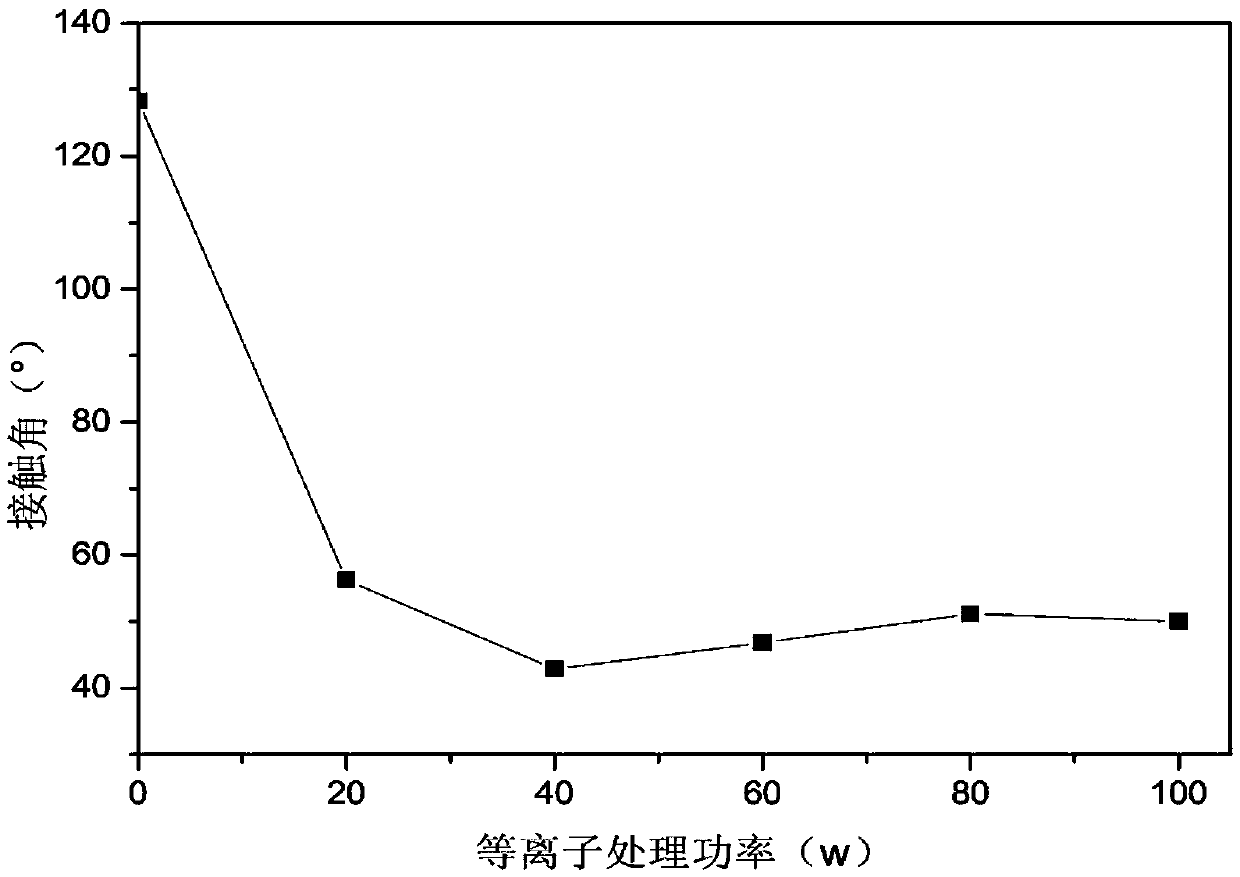

[0030] The plasma-treated PTFE microporous membrane was measured with a JY-82 contact angle meter (Chengde Testing Machine Factory), and the contact angle of water was measured at 6 different positions, and finally the average value was taken. The relationship between contact angle and plasma processing power is shown as figure 2 Shown. by figure 2 It can be known that the contact angle is between 40° and 60° at 20w to 100w. From the powe...

Embodiment 3

[0032] The pretreatment method of the PTFE microporous membrane is as in Example 1.

[0033] Plasma treatment:

[0034] Put the pretreated PTFE microporous membrane in the plasma high vacuum preparation chamber, 2 +CH 4 Under mixed gas, adjust the plasma treatment distance to 40cm and the gas flow rate to select 30cm 3 / s, the intake ratio is 1:1, that is, the gas flow rates of methane and nitrogen are both 10cm 3 / s, plasma processing power is 40w, control plasma processing time, the time is 20s, 40s, 60s, 80s, 100s.

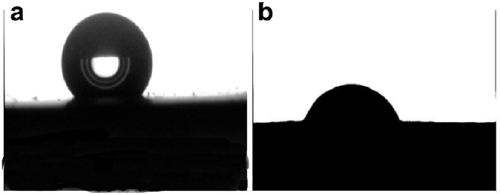

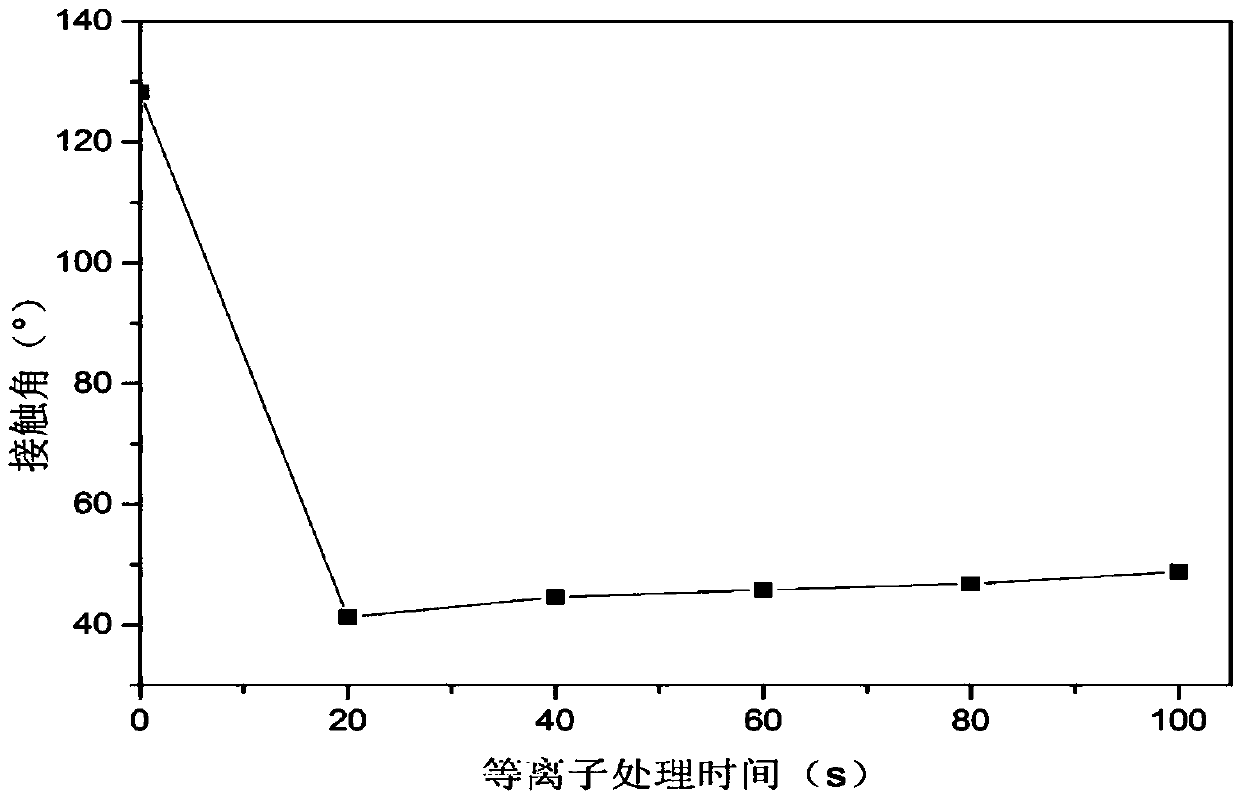

[0035] figure 1 It is the contact angle diagram of the untreated PTFE microporous membrane (a) and the PTFE microporous membrane (b) after plasma treatment. The relationship between contact angle and plasma treatment time is shown in image 3 Shown. From figure 1 It can be seen that the contact angle of the PTFE film before plasma treatment is 130°, and the contact angle after the final treatment reaches 40°. From image 3 It can be seen that before 20s, as the trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com