Superheated steam temperature adjusting system and method suitable for SCR low-load operation

A superheated steam temperature, low load technology, applied in the direction of superheated temperature control, steam superheating, preheating, etc., can solve the problems of being unable to put into operation, etc., to save environmental protection expenses, low system transformation and operation costs, and reduce investment costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

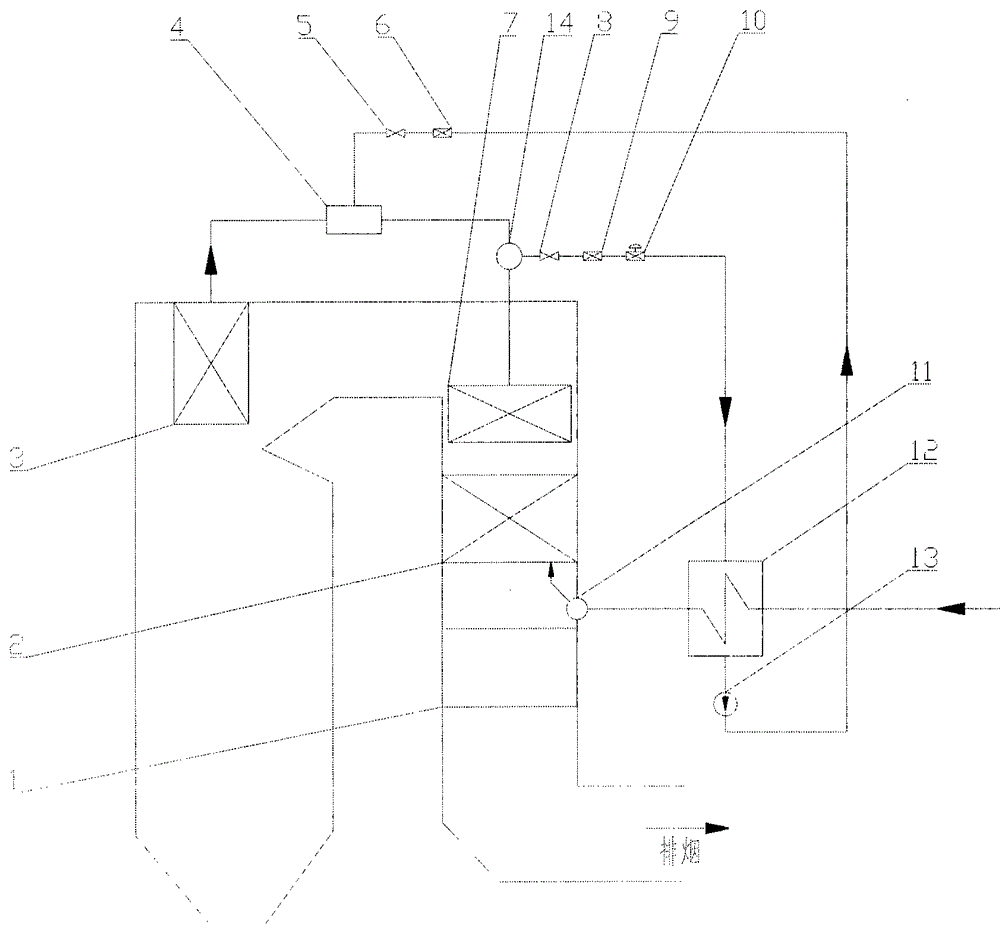

[0019] Such as figure 1 As shown, a superheated steam temperature adjustment system suitable for operation under low SCR load includes a steam bypass system connected to the outlet header 14 of the low-temperature superheater to the first-stage water spray desuperheating 4, and a steam bypass system arranged in the economizer Economizer inlet feed water heater 12 before the inlet header 11 and various pipes and valves connected to the steam temperature regulating system.

[0020] A superheated steam temperature adjustment method suitable for SCR operation under low load. According to the situation of SCR inlet smoke temperature when the boiler is low load, if the SCR operation conditions are not met, the first one-way valve 8 and the first stop valve 9 are opened. , the flow regulating valve 10, the second stop valve 6, and the second one-way valve 5, and by adjusting the opening of the flow regulating valve 10, the steam at the outlet of the low-temperature superheater flows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com