Ultrasonic assisting high-sensitivity detection system for pollutants in fluid and working method of ultrasonic assisting high-sensitivity detection system

An ultrasonic-assisted detection system technology, applied in the analysis of gas mixtures, measuring devices, particle size analysis, etc., can solve the problems of poor accuracy, poor consistency, and high price, and achieve enhanced fine particle concentration, improved detection accuracy, and good reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

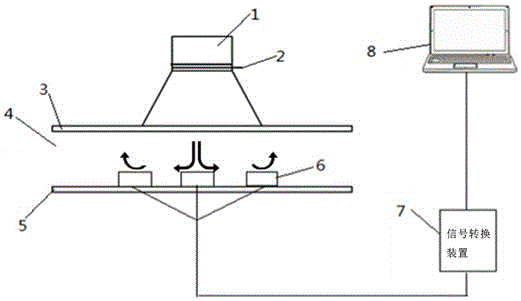

[0034] refer to figure 1, the ultrasonic transducer 1 is fixedly placed in the air environment with a bracket, when the excitation is applied to the electrode 2, the ultrasonic transducer 1 will generate vibration at the same frequency as the excitation, and the vibration will be amplified and transmitted through the sound radiation plate 3, and the radiation will be The sound field is generated in layer 4, and the pollutants in the radiation layer are moved by the sound field and the acoustic flow and acoustic vibration generated by it, and gather in a fixed area. The sensor 6 is placed at the position with the strongest acoustic flow and acoustic vibration effect to detect pollutants. Then, the signal processing conversion device 7 collects the induction signal in the sensor 6 and converts the signal into a signal recognized by the computer, and transmits it to the computer 8. Finally, the computer 8 calculates the corresponding position pollutant concentration according to t...

Embodiment 2

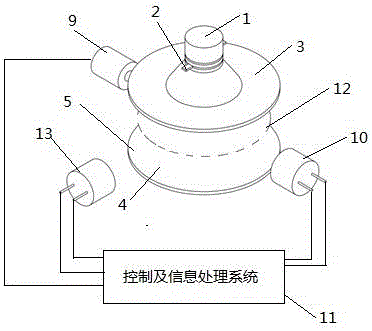

[0036] refer to figure 2 , the ultrasonic transducer 1 is fixedly placed in the air environment with a bracket, when the excitation is applied to the electrode 2, the ultrasonic transducer 1 will generate vibration at the same frequency as the excitation, and the vibration will be amplified and transmitted through the sound radiation plate 3, and the radiation will be The sound field is generated in the layer 4 and forms the nodal plane 12 of the sound field, and the fine particles in the radiation layer 4 gather near the nodal plane 12 of the sound field under the action of the acoustic radiation force, and then the laser emitting device 9 is placed where the emitting laser can pass through the nodal plane 12 of the sound field The position on one side of the radiation layer 4, the transmitted light receiving device 10 is arranged on the corresponding side of the laser emitting device 9, and the scattered light receiving device 13 is arranged on the front or rear of the radia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com