General spacecraft ground test bed system

A technology for ground testing and spacecraft, applied in general control systems, control/adjustment systems, instruments, etc., can solve problems such as missing the best time and conditions for discovery and problem solving, short development cycle, and affecting test progress, etc., to achieve The effective test time ratio is improved, the electrical performance consistency is high, and the test coverage rate is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

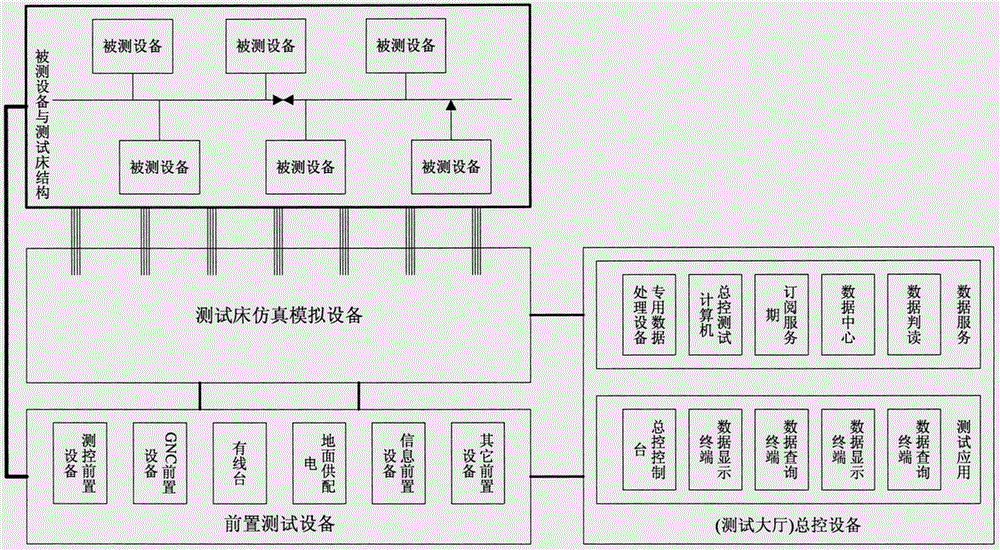

[0040] Such as figure 1 As shown, the general spacecraft ground test bed system of the present invention includes a test bed structure, test bed simulation equipment, front-end test equipment and general control equipment located in the test hall.

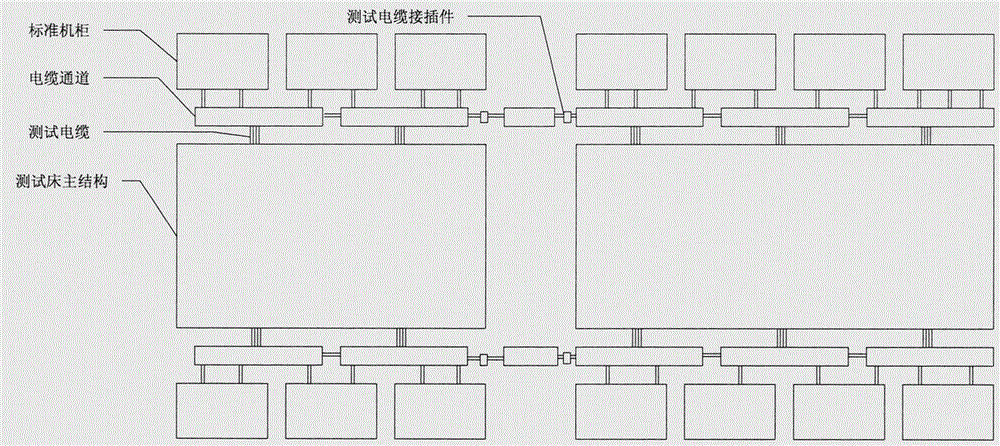

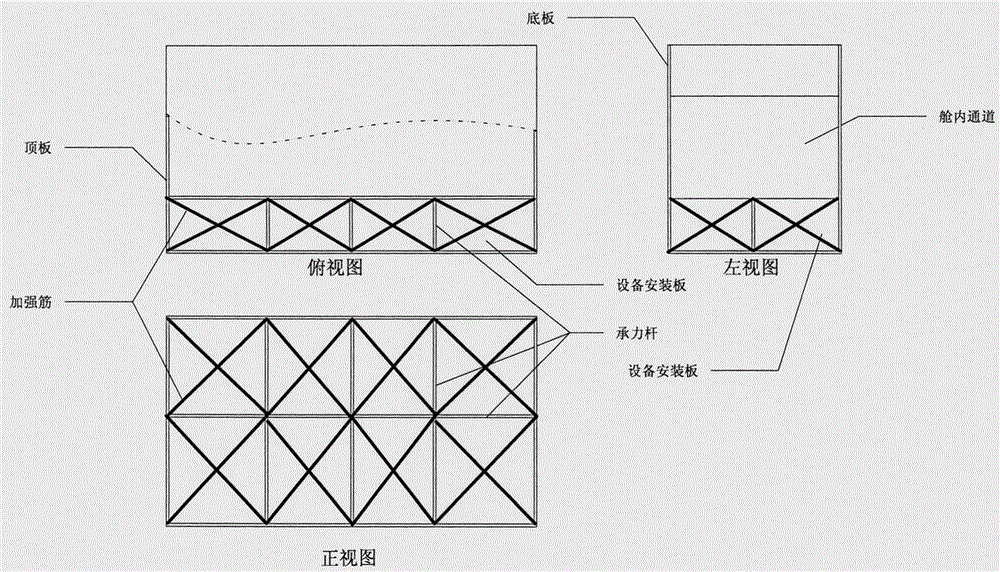

[0041] Such as figure 2 As shown, the structure of the test bed is a simple cabin structure, and an open frame cabinet that can be freely disassembled and combined is used to replace the real cabin structure. A set of test cables consistent with the design state can be used to carry, load, and Operate and connect electrical equipment under test and monitoring equipment dedicated to testing. The installation method of the equipment under test refers to the actual installation layout of the equipment in the cabin to ensure that the installation orientation of the equipment is similar to the actua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com