A kind of water purification material and preparation method thereof

A technology for water purification and composite materials, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc. Improve repair efficiency, improve easy agglomeration, and reduce repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: the preparation of water purification material

[0026] Raw material composition ratio: 60% of composite material, 20% of attapulgite, 10% of activated carbon with a particle size of 80 mesh, 4% of expanded graphite with an expansion rate of 330ml / g, and 6% of calcium carbonate;

[0027] The composite material is prepared by the following method: uniformly mix wood chips or sawdust with iron oxide at a mass ratio of 1:1.5, put them into a sealed crucible, then place the crucible in a muffle furnace, and adjust the temperature to 1000°C for dry distillation 8h, take it out and set aside.

[0028] The preparation method of water purification material comprises the following steps:

[0029] 1) Mix the composite material with attapulgite, activated carbon, expanded graphite and calcium carbonate according to the above ratio;

[0030] 2) Prepare a carboxymethyl cellulose solution with a concentration of 15%, slowly add it to the mixture prepared in step 1) un...

Embodiment 2

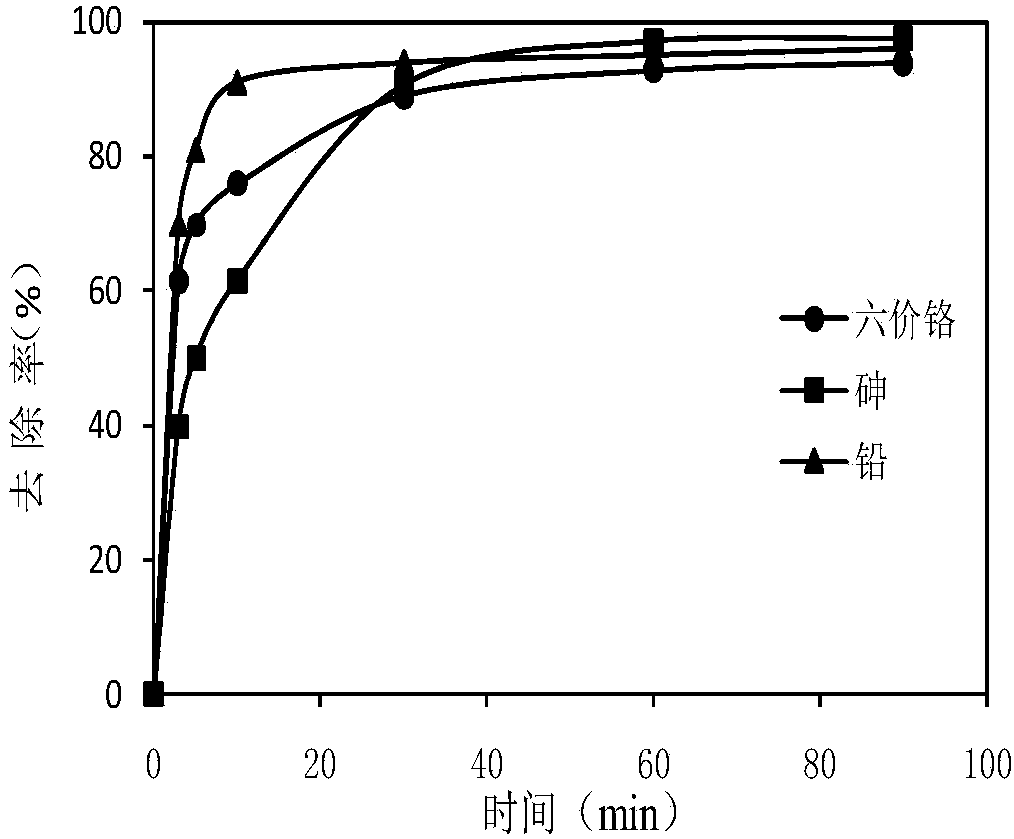

[0032] Embodiment 2: water body purification material is to Pb 2+ 、As 5+ 、Cr 6+ The removal experiment

[0033] The novel water purification material prepared by the present invention is carried out Pb 2+ 、As 5+ 、Cr 6+ removal rate test. Take 4.0g of the material and add it to 100ml of weakly acidic heavy metal polluted wastewater simulating that the above heavy metal is 50mg / L, divide it into three groups of parallel experiments, put it into a constant temperature oscillation box at 35°C for reaction, and take samples for measurement at regular intervals The heavy metal concentration in the water body is obtained to obtain the heavy metal removal curve of the material. From figure 2 It can be seen that the material prepared by the present invention has a good removal effect on various heavy metals, and the reaction is rapid, and a removal rate of more than 90% can be achieved within 30 minutes.

Embodiment 3

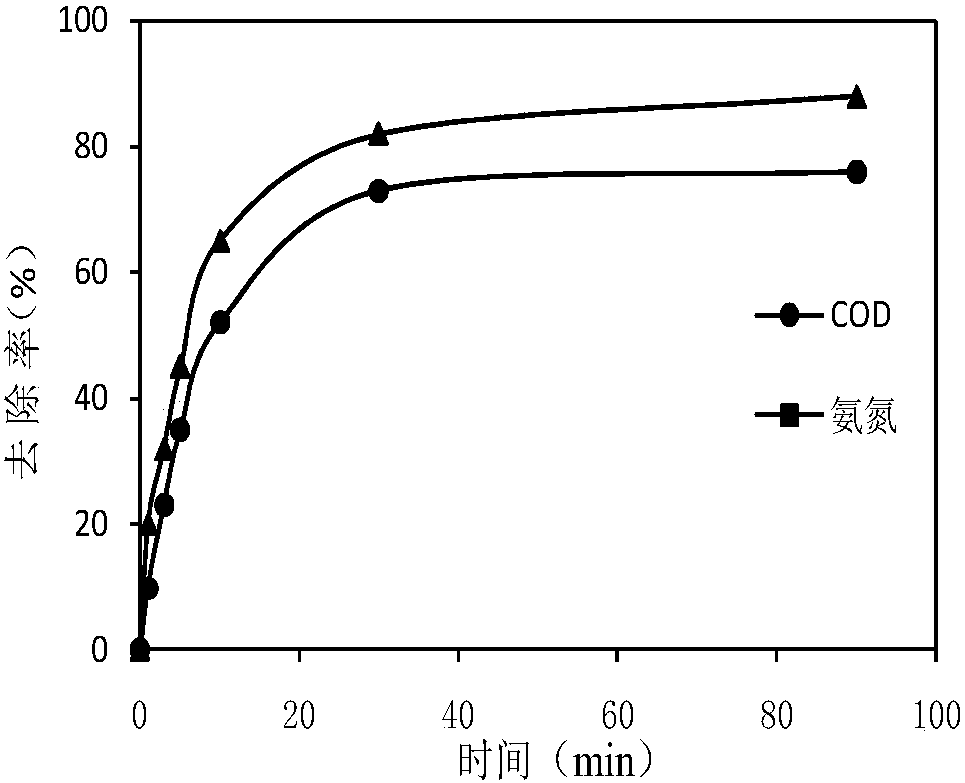

[0034] Embodiment 3: water body purification material is to NH 3 -N, COD removal experiment

[0035] The novel water purification material prepared by the present invention is carried out NH 3 -N, COD removal rate test. Take 4.0g of the material and add it to 100ml of domestic polluted wastewater, take 30% sodium hydroxide solution and 10% sulfuric acid solution to adjust the pH, divide it into three groups of parallel experiments, and put it into a constant temperature shaking box at 35°C for reaction , take samples at regular intervals to measure NH in water 3 -N, COD value, get the NH of the material 3 -N, COD removal curve. From image 3 It can be seen that: the material prepared by the present invention has 3 Both -N and COD have good removal effects, and the removal rate of more than 70% can be achieved within 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com