A short-process drinking water advanced treatment system and process

A technology for advanced treatment and drinking water, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the uncontrollable risk of activated carbon microbial leakage, aggravate membrane pollution load, and make water It can reduce the possibility of membrane fouling, solve the sensitivity of water impact, and achieve the effect of long operation cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 A short-flow drinking water advanced treatment system and process

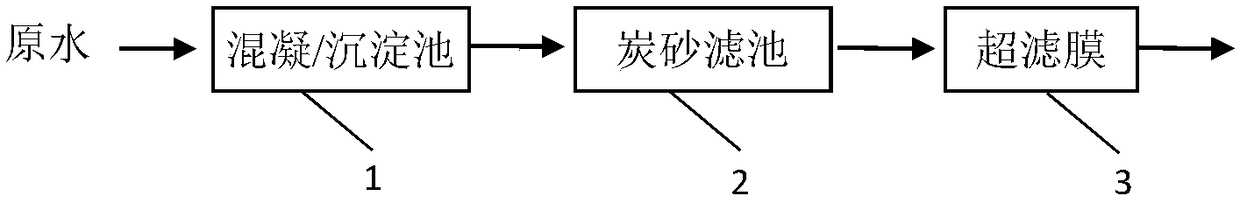

[0031] Such as figure 1 As shown, a short-process drinking water advanced treatment system includes: a coagulation / sedimentation tank 1, a carbon sand filter 2, and an ultrafiltration membrane workshop 3. The treatment process includes: the effluent of the coagulation sedimentation tank 1 is transported to the carbon sand filter 2 through pipelines, and the effluent of the carbon sand filter is directly pressurized by the water pump and then enters the ultrafiltration membrane workshop 3 to complete the advanced treatment process of drinking water.

[0032] in, figure 1 The coagulation-sedimentation tank 1 described in has various forms, and the core process described in this patent can adapt to the effluent of various coagulation-settling tanks, so the coagulation-settling tank 1 will not be described in detail.

[0033] Preferably, the carbon sand filter is filled with quartz sand and a...

Embodiment 2

[0034]Embodiment 2 A short-flow drinking water advanced treatment system and process

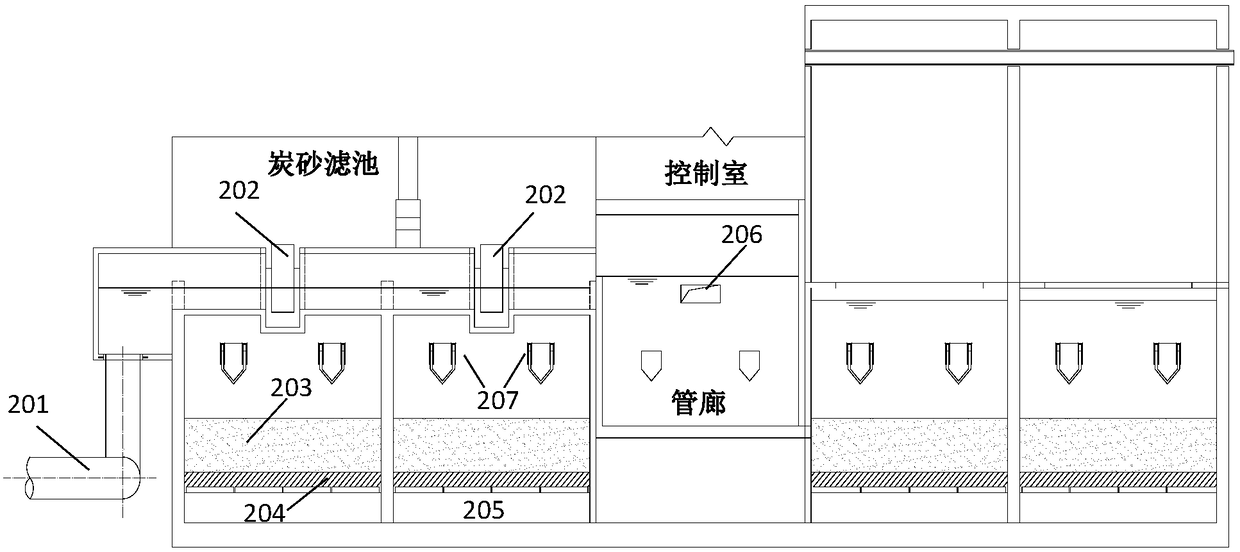

[0035] Such as figure 1 and 2 As shown, on the basis of the short-flow drinking water advanced treatment system and process described in Embodiment 1, the carbon sand filter 2 has a filter water inlet pipe 201 and a siphon water inlet pipe 202 . The outlet water from the sedimentation tank is transported to the filter tank by the filter tank water inlet pipe 201, and then siphons into the filter tank through the siphon water inlet pipe 202. The filter is filled with activated carbon 203 and fine sand 204 from top to bottom. The precipitated water first passes through the activated carbon 203 to complete the adsorption of pollutants and microbial degradation process, and then passes through the fine sand 204 to control the particulate matter in the effluent from the filter. After being filtered by the fine sand 204, the water is collected through the catchment area 205, and then enters the ...

Embodiment 3

[0036] Embodiment 3 A short-flow drinking water advanced treatment system and process

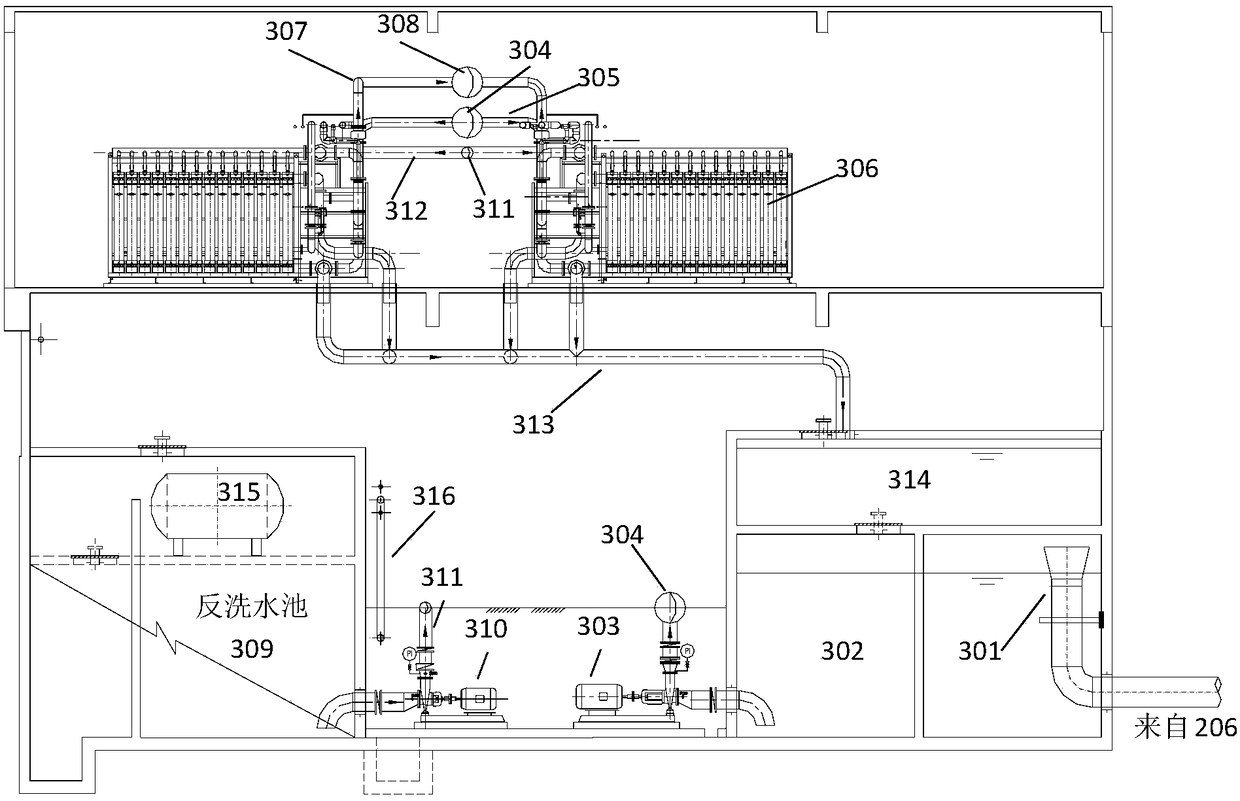

[0037] Such as figure 1 , 2 As shown in and 3, on the basis of a short-flow drinking water advanced treatment system and process described in Examples 1 and 2, the ultrafiltration membrane workshop has two upper and lower floors, and the lower floor is a semi-underground structure. The ultrafiltration membrane workshop has an ultrafiltration membrane water absorption pool 302, and the carbon sand filter effluent from the clear water channel 206 is transported to the water absorption pool 302 through the water inlet pipe 301 of the ultrafiltration membrane water absorption pool. After being pressurized by the ultrafiltration membrane water inlet pump 303, the water in the suction pool 302 is lifted to the second floor of the ultrafiltration membrane workshop through the ultrafiltration membrane water inlet main pipe 304, and is transported to different membrane groups through the ultrafiltr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com