Fluidized bed photocatalytic three-dimensional electrolytic reactor and application thereof

An electrolytic reactor, photocatalytic three-dimensional technology, applied in chemical instruments and methods, special compound water treatment, light water/sewage treatment, etc., can solve three-dimensional electroreactor electrode blockage, reactor stability deterioration, reduce electrolysis Efficiency and other issues, to achieve the effect of solving electrode blockage and short circuit, helping to decompose, and increasing the amount of dissolved oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

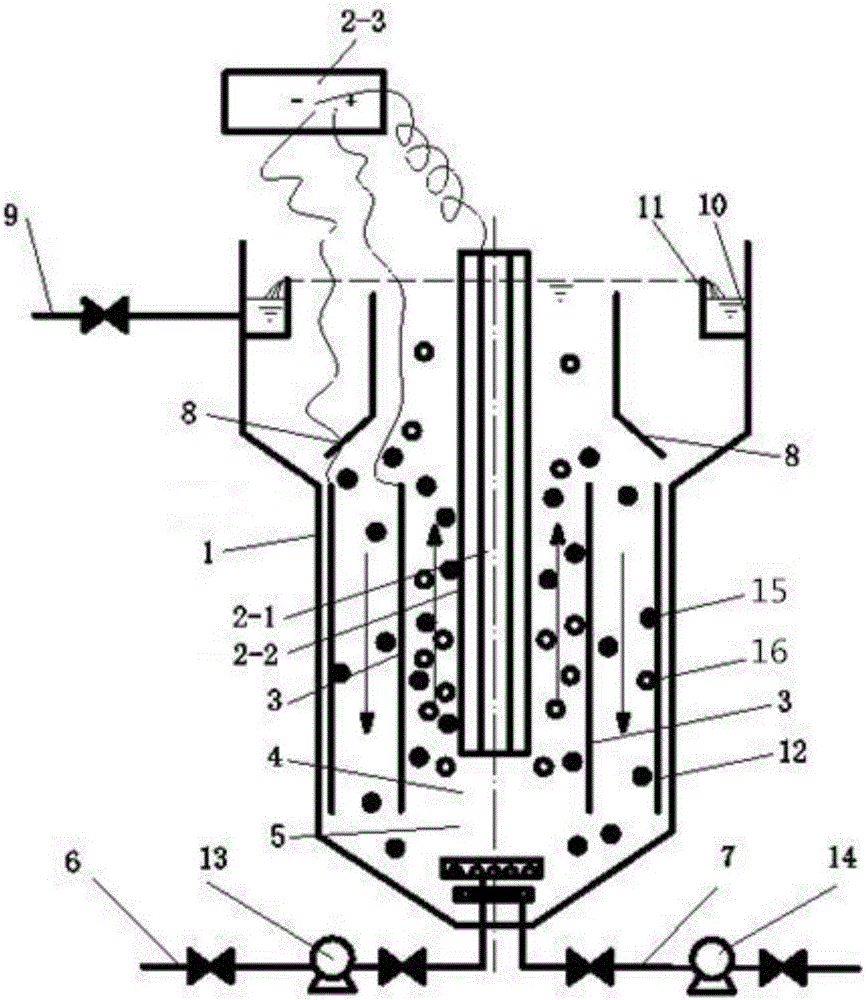

[0021] Such as figure 1 The shown fluidized bed photocatalytic three-dimensional electrolysis reactor includes an electrolytic cell, a cathode 12, an anode 3 and a particle electrode arranged in the electrolytic cell, and a water inlet pump 13, an air pump 14, a perforated tube water distributor 4, a perforated tube exposure Gas vessel 5, water inlet pipe 6, air inlet pipe 7, water outlet pipe 9, described electrolyzer comprises photocatalytic oxidation reactor outer wall 1, the cylindrical electrolytic reaction zone in the wall, the funnel-shaped that is fixed on the electrolytic reaction zone top The solid-liquid separation area, and the water distribution and gas distribution area connected to the lower part of the electrolysis reaction area. The ratio of the inner diameter of the electrolytic cell to the height of the electrolytic reaction zone is 1:5.

[0022] There is an outlet in the solid-liquid separation area, and an inlet at the bottom of the water and gas distribu...

Embodiment 3

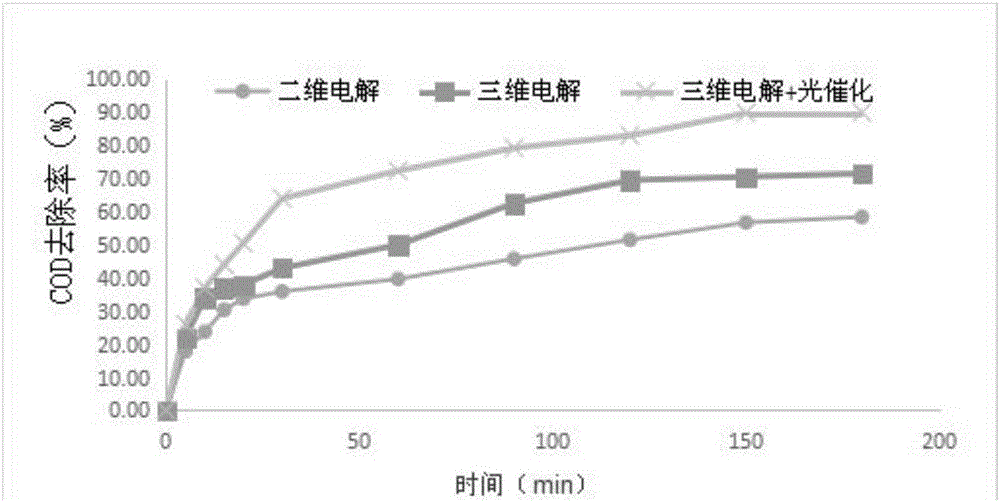

[0030] The reactor of Example 1 was used to treat the printing and dyeing wastewater in the textile park. The wastewater quality is: COD 498-1257mg / l, BOD 131.21-200.53mg / l, pH 9-11, turbidity 880-7832NTU, chroma 210-632 times. The cell voltage is 12V, the electrolysis time is 90min, and the expanded state density of the particle electrode is 40kg / m 3 , the wavelength of ultraviolet rays is 254nm, and the power is 100W. The wastewater enters the photocatalytic reaction zone and electrolytic reaction zone from the inlet pump through the water flow distributor at the bottom of the tank. The treated wastewater is discharged after solid-liquid separation. Wastewater treatment effect see image 3 .

[0031] If load TiO in the spherical particle photocatalytic electrode of embodiment 1 2 The COD removal rate decreased by 3.52% when the particle diameter of granular activated carbon was adjusted to 45 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com