Treatment method and treatment device of oil sludge sand

A treatment method and oil sludge sand technology, which is applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problems of high energy consumption in incineration, difficult settlement and dehydration, leakage, leakage, etc. and other problems, to achieve the effect of reducing operating costs, simple process, and clear water phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

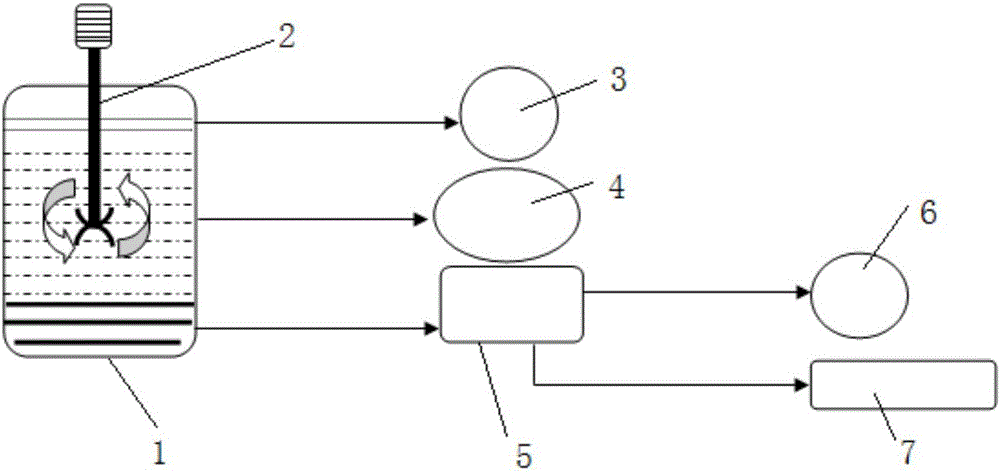

Image

Examples

Embodiment 1

[0060] An oil field produces oil sludge sand

[0061] The oily sand is universal and representative in China. Currently there is no good way to deal with it, and the treatment efficiency is particularly low, especially because the large amount of water produced after removing the sand and oil-polymer mixture still contains heavy oil, polymers, a small amount of sand, and mud. , It is difficult to dispose of. Only after the heavy oil sludge and water are clearly separated can the follow-up treatment of heavy oil sludge be facilitated, and the water can be reused. Water without heavy oil sludge can also be used for oilfield sewage after repeated use. Treatment plant disposal. By adopting the treatment process of the invention, the water content of the sludge containing heavy oil can be reduced to below 75%.

[0062] Process flow: In the early stage, the weight ratio of oil sludge sand: water = 1:3 is mixed and diluted, with a total weight of 4 tons, and most of the sand and oil-p...

Embodiment 2

[0065] Aged oil mud sand left over from the history of an oilfield

[0066] Due to the long aging time and high degree of hardening, the aged oil sludge sand is very difficult to handle. First, the aged oil sludge sand needs to be pulverized and refined, then diluted with water and soaked in a certain proportion, and finally disposed of according to the treatment process of new oil sludge sand.

[0067] Process flow: Take 100g of crushed aged oil sludge sand and 900g of water, mix and dissolve them in a 1L beaker, and stir thoroughly; add natural polymer compound components, polyferric sulfate, and calcium hydroxide successively, among which the natural polymer compound components 1.2‰ (volume percentage), the total concentration of polyferric sulfate is 6mmol / L, adjust the pH value to 7.5 with calcium hydroxide; mechanically stir for 2min; stand for 40min; the lower layer of sediment is dehydrated by vacuum filtration.

[0068] Results: After drying and before and after dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com