A kind of waste tire desulfurization rubber and its chlorinated derivative modified asphalt composite material

A technology of discarded tires and desulfurized rubber, which is applied in solid waste management, building insulation materials, sustainable waste treatment, etc., can solve the problems of inability to melt into asphalt homogeneously, and achieve the effect of increasing added value, good affinity, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

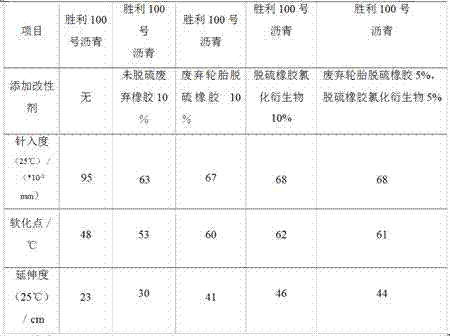

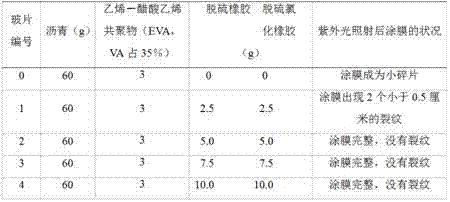

[0036]Heat 300 parts of Liaohe Oilfield AH-90 bitumen and 15 parts of ethylene-vinyl acetate copolymer (EVA, the proportion of vinyl acetate is 19%) of Beijing Oil Chemical Co., Ltd. to 190 ° C, stir and mix evenly, divide into five parts and load them separately Stainless steel container, one part of asphalt is not added with waste tire devulcanized rubber and its chlorinated derivatives, and the other four parts of asphalt ethylene-vinyl acetate copolymer mixture are added with 5 parts, 10 parts, 15 parts and 20 parts of waste Tire desulfurized rubber and its chlorinated derivatives (the proportions of waste tire desulfurized rubber and desulfurized rubber chlorinated derivatives are 50% each), stir the mixed solution and heat, the heating temperature is 172 ° C, and keep stirring for 60 minutes, so that The waste tire desulfurized rubber and its chlorinated derivatives are dissolved and mixed with asphalt evenly, and then the asphalt and four parts of waste tire desulfurized...

Embodiment 2

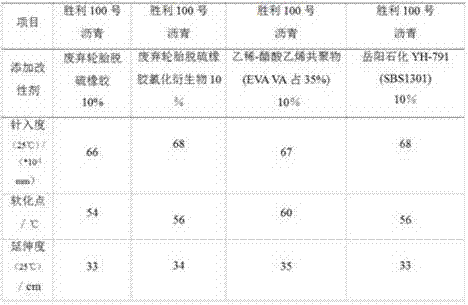

[0040] Heat 300 parts of Shengli No. 100 asphalt to 160°C, divide it into five parts and put them into stainless steel containers, one part of the asphalt is not added with waste tire desulfurization products or chlorinated derivatives of desulfurized rubber, and the other three parts are added with 5 parts of undesulfurized Waste tire powder, 10 parts of waste tire desulfurized rubber powder, 10 parts of waste tire desulfurized rubber chlorinated derivatives; there is also a mixture of 5 parts of waste tire desulfurized rubber powder and 5 parts of waste tire desulfurized rubber chlorinated derivatives added to one part of asphalt, Stir the mixture with asphalt and heat it. The heating temperature is 175°C, and keep stirring for 60 minutes to dissolve and mix the above-mentioned modified additives and asphalt evenly. Cool to room temperature and measure its penetration according to the corresponding industry standards (JTJ036-98), Softening point (ASTMD36-26) and elongation (a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com