Process for synthesizing pure phenyl chloroformate

A technology for the synthesis of phenyl chloroformate, applied in the preparation of phosgene or haloformate, the preparation of organic compounds, organic chemistry, etc., can solve the problems of low production efficiency, high production cost, complicated post-treatment, etc., and achieve The effect of low cost, shortened reaction time, improved purity and reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

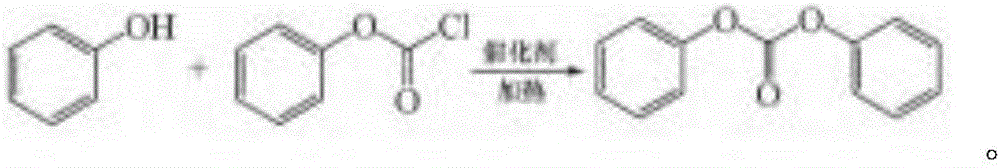

Image

Examples

Embodiment 1

[0025] The first choice is to add 400L of absolute ethanol to the reaction kettle, dissolve 230Kg of sodium metal in it, then add 188Kg of phenol, heat and undergo reflux reaction, transfer the reacted material to a distillation tower, and carry out vacuum distillation to remove ethanol to obtain phenol sodium;

[0026] Secondly, the above-mentioned sodium phenate of the weight after the vacuum distillation of the distillation tower is transferred to the stirred reactor, one side of the stirred reactor is connected with a circulating refrigerator, the outer side of the stirred reactor is provided with a jacket, and the outer wall of the stirred reactor is provided with A temperature control pipeline, the temperature control pipeline is connected with a circulating refrigerator, the temperature control pipeline is located in the jacket of the stirred reactor, and a thermometer is inserted at the top of the stirred reactor;

[0027] Turn on the circulating freezer first again, l...

Embodiment 2

[0032] The first choice is to add 400L of absolute ethanol to the reaction kettle, dissolve 230Kg of sodium metal in it, then add 188Kg of phenol, heat and undergo reflux reaction, transfer the reacted material to a distillation tower, and carry out vacuum distillation to remove ethanol to obtain phenol sodium;

[0033] Secondly, the above-mentioned sodium phenate of the weight after the vacuum distillation of the distillation tower is transferred to the stirred reactor, one side of the stirred reactor is connected with a circulating refrigerator, the outer side of the stirred reactor is provided with a jacket, and the outer wall of the stirred reactor is provided with A temperature control pipeline, the temperature control pipeline is connected with a circulating refrigerator, the temperature control pipeline is located in the jacket of the stirred reactor, and a thermometer is inserted at the top of the stirred reactor;

[0034] Turn on the circulating freezer first again, l...

Embodiment 3

[0040] The first choice is to add 400L of absolute ethanol to the reaction kettle, dissolve 230Kg of sodium metal in it, then add 188Kg of phenol, heat and undergo reflux reaction, transfer the reacted material to a distillation tower, and carry out vacuum distillation to remove ethanol to obtain phenol sodium;

[0041] Secondly, the above-mentioned sodium phenate of the weight after the vacuum distillation of the distillation tower is transferred to the stirred reactor, one side of the stirred reactor is connected with a circulating refrigerator, the outer side of the stirred reactor is provided with a jacket, and the outer wall of the stirred reactor is provided with A temperature control pipeline, the temperature control pipeline is connected with a circulating refrigerator, the temperature control pipeline is located in the jacket of the stirred reactor, and a thermometer is inserted at the top of the stirred reactor;

[0042] Turn on the circulating freezer first again, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com