Synthesis method of zoalene

A synthesis method and technology of qiuli-ling are applied in the synthesis field of anti-coccidial medicine qiu-li-ling, which can solve the problems such as the accumulation of a large amount of sulfuric acid, a large amount of waste ammonia water, and the increase, so as to avoid product quality, improve utilization rate, and avoid waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

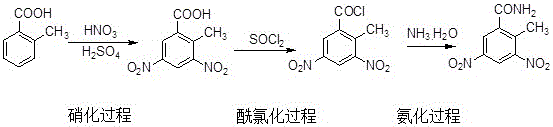

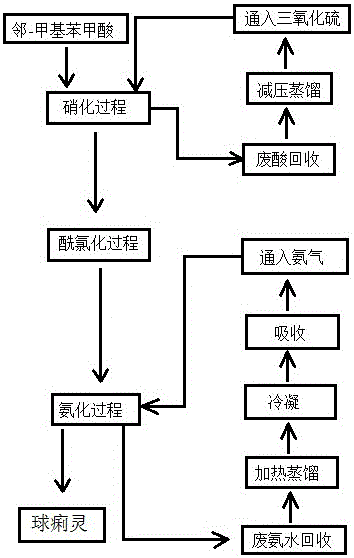

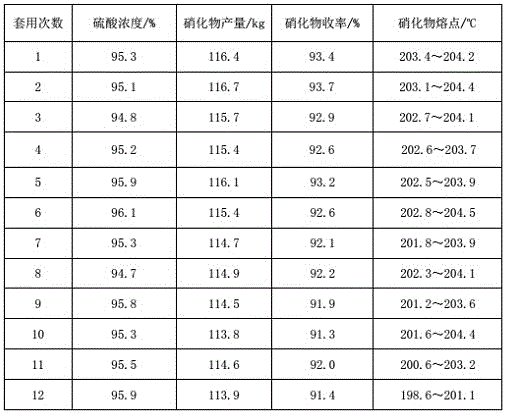

[0031] Such as figure 1 , figure 2 A synthetic method of cocifluazol shown includes the following steps A, nitration process, step B, acyl chloride process, step C, ammonification process. In the nitration process of step A, put 300L of concentrated sulfuric acid into the enamel reaction kettle, turn on the agitator, then put in 75kg of o-toluic acid, stir until it is completely dissolved, then add 65L of nitric acid dropwise into the above system, and control the temperature of the system , continue to stir after dripping, cool, dilute feed liquid with distilled water, filter, the gained solid is through washing with water, dry to obtain nitration product 3,5-dinitro-o-toluic acid 117kg, yield is 93.9%.

[0032] In the step polymerization A, the recovery and reuse process of concentrated sulfuric acid is set, and the recovery and reuse process of the concentrated sulfuric acid is set to first recycle the waste acid 726L produced after nitration reaction dilution and washing...

Embodiment 2

[0035] Such as figure 1 , figure 2A synthetic method of cocifluazol shown includes the following steps A, nitration process, step B, acyl chloride process, step C, ammonification process. Step A is the same as in Example 1 during the nitration process. In step A, the recovery and reuse process of the concentrated sulfuric acid is set to first recycle the waste acid 750L produced after the nitration reaction dilution and washing, and then pass the waste acid to into the distillation pot for vacuum distillation, the temperature of the vacuum distillation is set to 150°C, the vacuum degree is set to 0.09MPa, the concentration of sulfuric acid is concentrated to 85%, and at the same time the residual nitric acid in the waste acid is evaporated, and the concentrated sulfuric acid is passed into Sulfur trioxide 95kg, stirred 1 hour, left standstill 4 hours again, can prevent like this from containing sulfur trioxide in sulfuric acid and take place sulfonation side reaction; Pass t...

Embodiment 3

[0038] Such as figure 1 , figure 2 The synthetic method of a kind of cudaloxine shown comprises the following steps A, nitration process, step B, acyl chloride process, step C, ammonification process, step A nitration process is the same as Example 1, and in step A, concentrated The process of sulfuric acid recovery and reuse is set as follows: first, 720L of waste acid produced after nitration reaction dilution and washing is recovered, and then the waste acid is passed into the distillation kettle for vacuum distillation. The temperature of vacuum distillation is set at 130°C, and the vacuum degree Set it to 0.08MPa to concentrate the sulfuric acid concentration to 80%, and at the same time distill off the residual nitric acid in the waste acid, pass 93kg of sulfur trioxide into the concentrated sulfuric acid, stir for 1.5 hours, and then let it stand for 6 hours, then pass in sulfur trioxide Finally, make the concentration of the prepared concentrated sulfuric acid reach ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com