Method for continuous production of acetyl phosphate with microchannel reaction device

A channel reaction device and a technology of acetyl phosphate, which are applied in the fields of chemical synthesis and technology, can solve the problems of low purity and yield of reaction products, and achieve the effects of short reaction time and good mass transfer effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

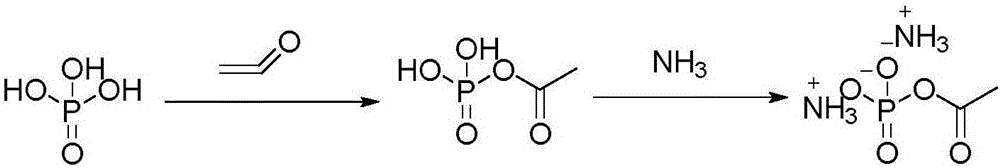

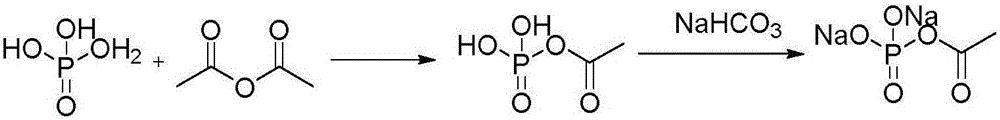

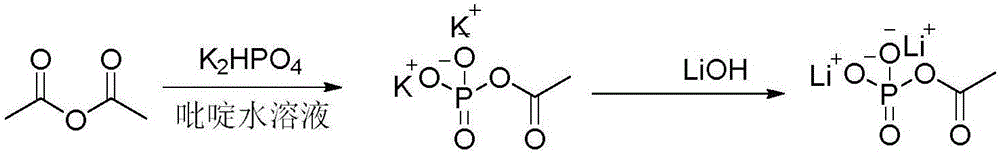

Image

Examples

Embodiment 1

[0038] Configure the methanol solution of phosphoric acid in the first raw material storage tank, the proportioning of phosphoric acid and methyl alcohol is 1mol:300ml, configure the ethyl acetate solution of acetic anhydride in the second raw material storage tank, the proportioning of acetic anhydride and ethyl acetate is 1mol: 200ml. Wait for the pump to enter the microstructure mixer and enter the microchannel reactor for reaction.

Embodiment 2~3

[0040] Pump the first raw material storage tank (methanol solution of phosphoric acid) and the second raw material storage tank (ethyl acetate solution of acetic anhydride) according to the volume flow ratio of 1:2 (embodiment 2), 1:4 (embodiment 3) Put it into the microchannel reactor, keep it for 10min under the reaction condition of 0°C, and take the reaction solution from the microchannel reactor I for detection.

[0041] Selectivity and conversion rate of table 1 embodiment 2~3

[0042] Example Phosphoric acid conversion rate Acetyl phosphate selectivity 2 100% 94% 3 100% 93%

Embodiment 4~6

[0044] The first raw material storage tank (methanol solution of phosphoric acid) and the second raw material storage tank (ethyl acetate solution of acetic anhydride) are pumped into the microchannel reactor according to the volume flow ratio of 1:2.5, at -5 ℃ (embodiment 4 ), 0 ℃ (embodiment 5), 5 ℃ (embodiment 6) reaction conditions, retain 10min, get the reaction liquid detection that microchannel reactor 1 comes out.

[0045] Selectivity and conversion rate of table 2 embodiment 4~6

[0046] Example Phosphoric acid conversion rate Acetyl phosphate selectivity 4 100% 90% 5 100% 92.4% 6 100% 87.6%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com