Micro-channel preparation method of tetra-n-butylammonium polyiodide

A technology of tetra-n-butylammonium and n-butylammonium, applied in chemical instruments and methods, preparation of amino compounds from amines, chemical/physical/physical-chemical processes, etc., can solve the problem of product decomposition, residual iodine, temperature sensitivity, etc. problem, to achieve the effect of good mass transfer effect, high yield and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

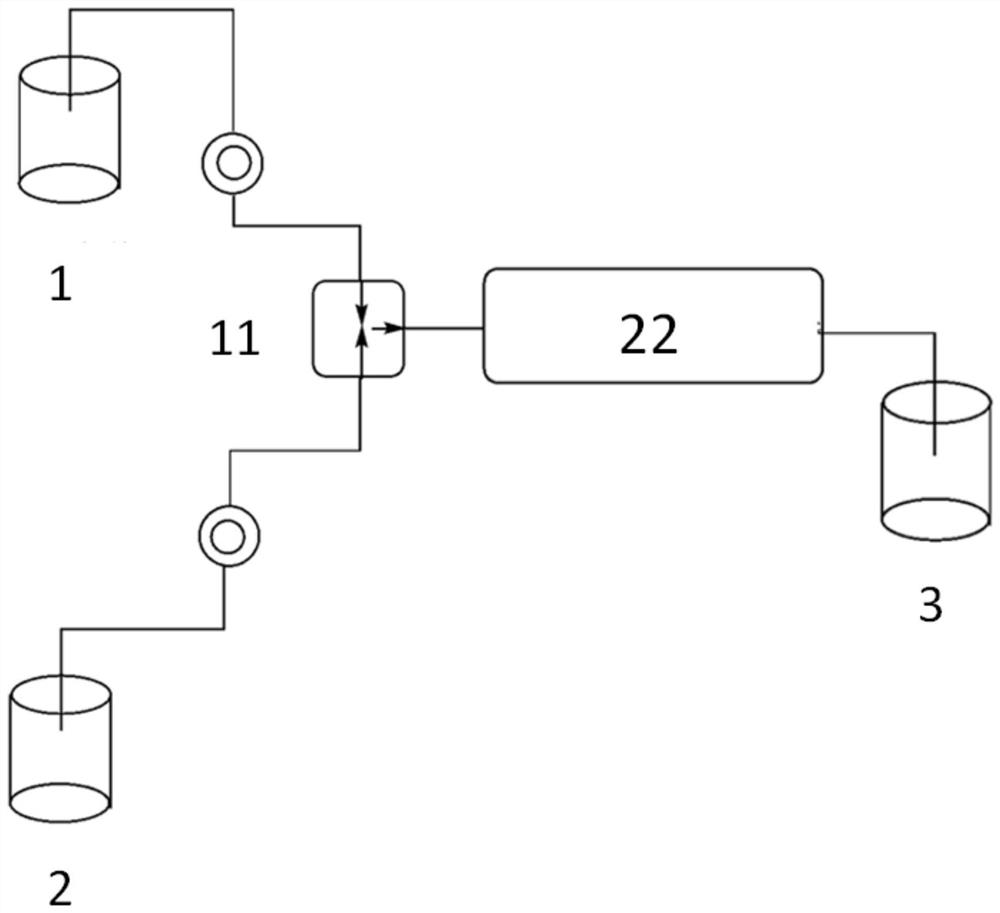

[0035] A kind of microchannel preparation method of tetra-n-butylammonium polyiodine, the method comprises the following steps:

[0036] (1) Tetra-n-butylammonium iodide ethanol solution and iodine ethanol solution are pumped into the microchannel reaction device respectively simultaneously, uniformly mixed and reacted to obtain a black flowing melt containing tetra-n-butylammonium high polyiodine; tetra-n-butylammonium In the butylammonium iodide ethanol solution, the concentration of the solute tetra-n-butylammonium iodide is 4-5mol / L; in the iodoethanol solution, the concentration of the solute iodine is 4-5mol / L;

[0037] (1-1) The tetra-n-butylammonium iodide ethanol solution in the first feed tank 1 and the iodine ethanol solution in the second feed tank 2 are pumped into the microstructure mixer 11 and mixed uniformly; The volume flow ratio of ammonium ethanol solution and iodine alcohol solution is (1-2): 1, preferably (1.5-2): 1;

[0038] (1-2) The mixed liquid is in...

Embodiment 1

[0042] The tetra-n-butylammonium iodide ethanol solution configured in the first feed tank 1, the tetra-n-butylammonium iodide ethanol solution, the proportioning of tetra-n-butylammonium iodide and ethanol is 1mol:200ml; In the second material The ethanol solution of iodine is configured in tank 2, and the proportioning of iodine and ethanol is 1mol:250ml. Wait to be pumped into the microstructure mixer 11 and enter the microchannel reactor 22 for reaction.

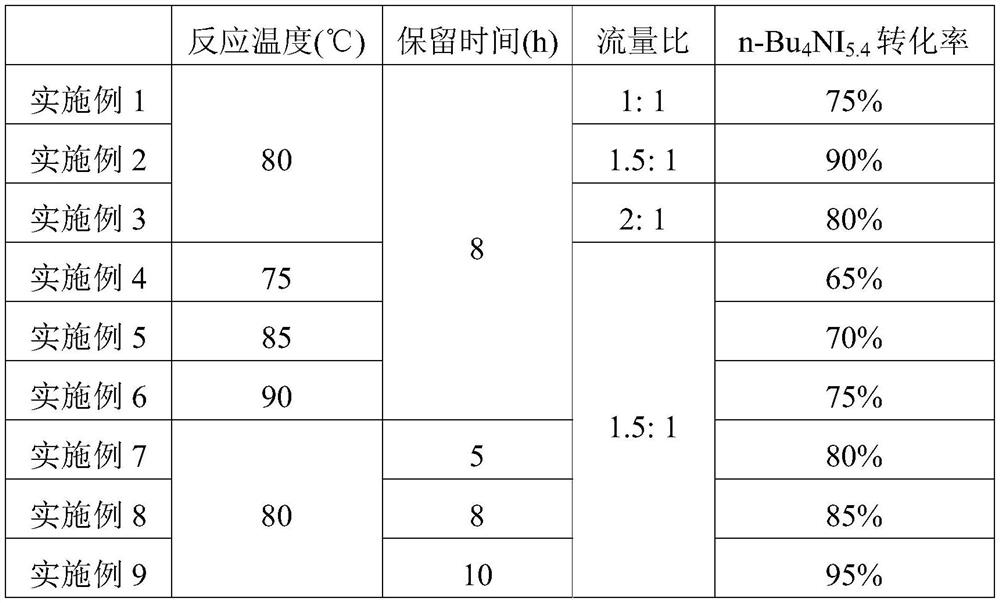

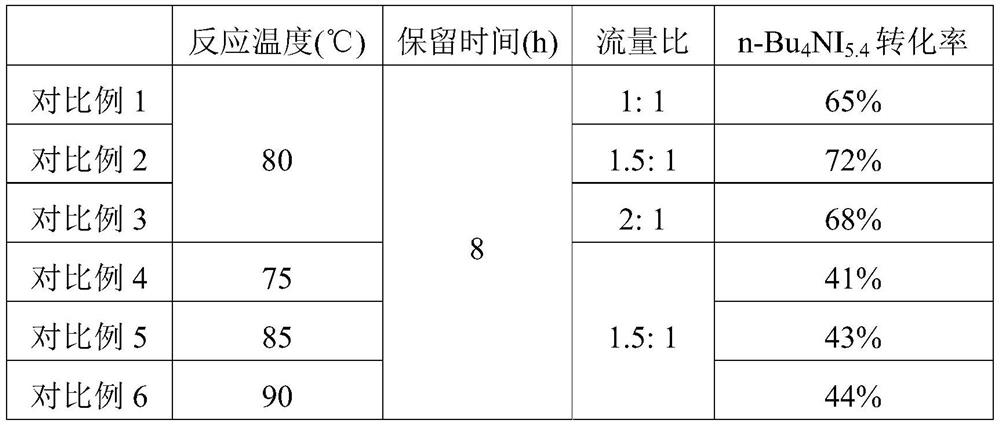

[0043] The first feed tank 1 and the second feed tank 2 are pumped into the microchannel reactor 22 according to the volume flow ratio, and kept at a certain temperature for a period of time, and the reaction solution from the microchannel reactor 22 is taken to detect four The productive rate and the purity of n-butylammonium polyiodine, specific conditions and results are shown in Table 1.

[0044] Embodiment 2-9 differs from Example 1 only in that the volume flow ratio of reaction temperature, retention time, tetra-n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com