Catalyst for preparing alcohol from coke quenching waste gas and preparation method thereof

A catalyst and waste gas technology, applied in the field of coking, can solve the problem of expensive catalyst, and achieve the effects of environmental protection, high selectivity, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0057] Examples 1-6 provide specific preparation methods of the coke-quenching exhaust gas alcohol production catalyst, and the coke-quenching exhaust gas alcohol production catalyst of the present invention is prepared.

[0058] The preparation method of each embodiment adopts following basic ideas:

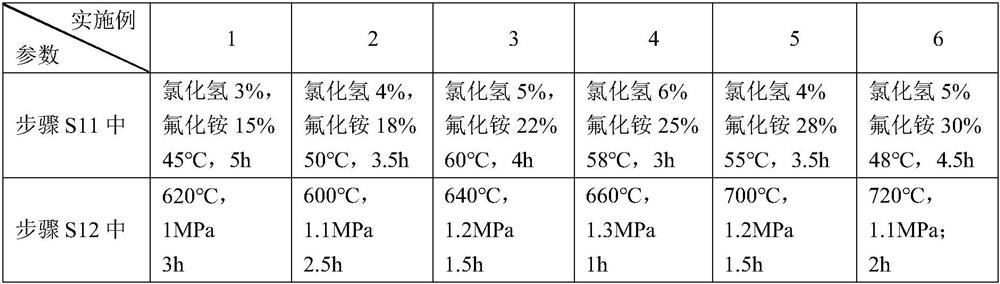

[0059] S1, using hydrochloric acid-ammonium fluoride aqueous solution to carry out pore expansion pretreatment on silica, specifically including the following process:

[0060] S11, prepare hydrochloric acid-ammonium fluoride aqueous solution, wherein the mass fraction of hydrogen chloride is 3-6%, the mass fraction of ammonium fluoride is 15-30%, heat to 45-60°C, then add silica powder, and stir at constant temperature 3 to 5 hours, filter, wash, and collect the filter cake;

[0061] S12, treating the filter cake in steam at 600-720° C. and 1.0-1.3 MPa for 1-3 hours, and then drying.

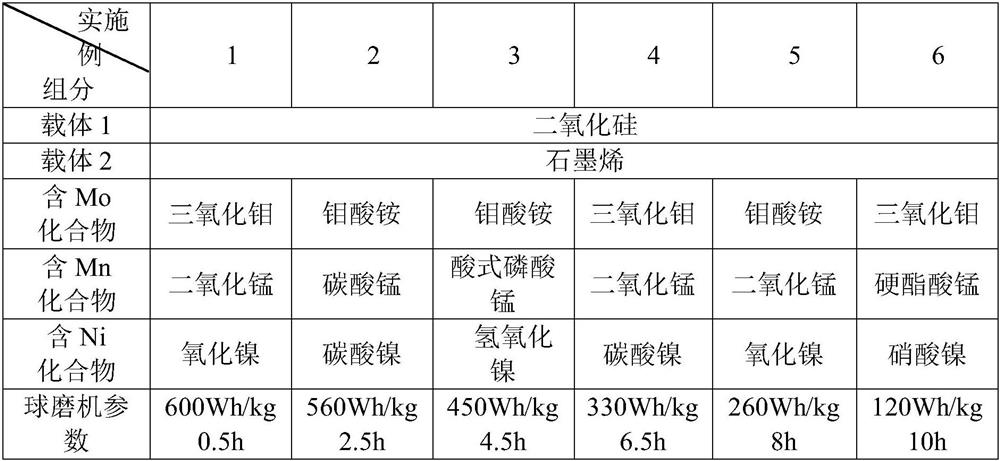

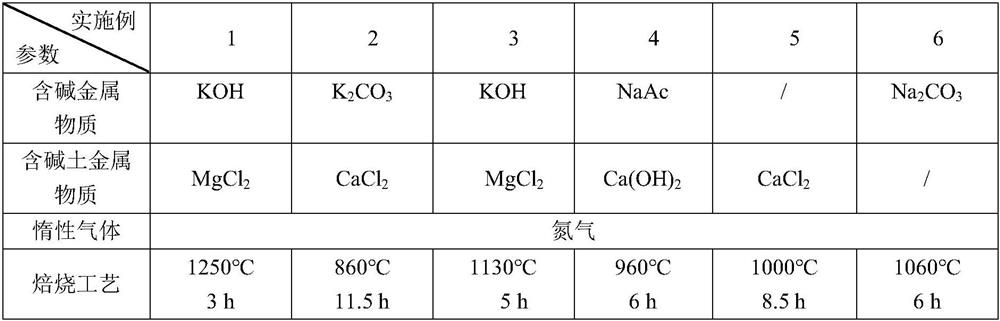

[0062] S2, mixing the silicon dioxide obtained in step S1 with graphene, a compound contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com