Preparation method of dry pricklyash peel oil

A technology of Zanthoxylum bungeanum oil and dried Zanthoxylum bungeanum, which is applied in the direction of fat oil/fat production and fat generation, can solve the problem of high extraction rate, achieve high extraction efficiency, shorten extraction time, and improve utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

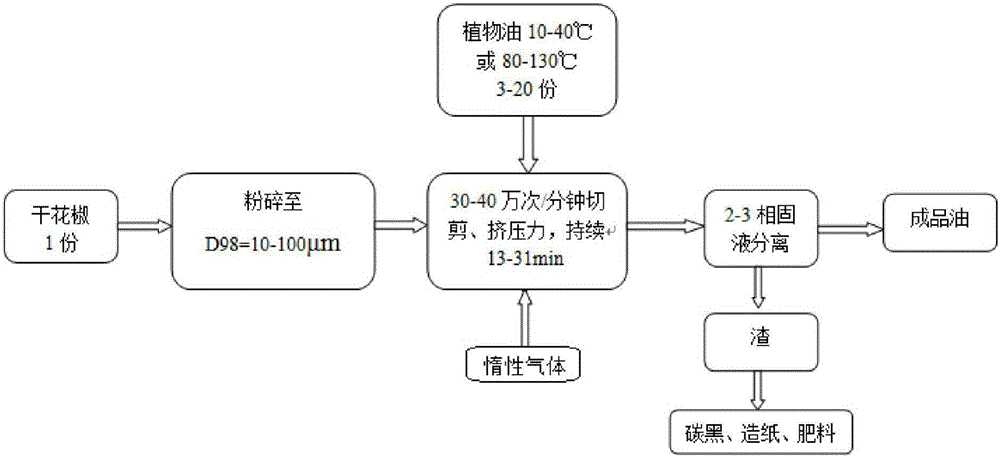

[0030] A preparation method of dried Zanthoxylum bungeanum oil of the present invention adopts mass transfer extraction of particle interface material, grinds dried Zanthoxylum bungeanum raw material to D98=10-100 μm powder and mixes it with vegetable oil, and then applies 300,000-400,000 times / min to Zanthoxylum bungeanum powder and vegetable oil The shearing and extrusion force, followed by solid-liquid separation to obtain the finished Zanthoxylum bungeanum oil.

[0031] The principle of particle interface mass transfer extraction: the smaller the particle, the larger the surface area, and the greater the surface energy, the particle interface will adsorb molecular substances to form a stable structure. At this time, strong mechanical energy is used to break through the gap barrier between particles and molecular substances. Its substance moves from the particle interface to the solvent.

[0032] see figure 1 , the above method specifically includes the following steps:

...

Embodiment 1

[0045] Step 1, take 1kg of dried Zanthoxylum bungeanum, pulverize to the Zanthoxylum bungeanum powder that average particle size is D98=80 μm;

[0046] Step 2, adding Chinese prickly ash powder and 8 kg of vegetable oil preheated to 30°C or 100°C into a vibrating refiner (stick type);

[0047] Step 3, in a fully enclosed environment and under the protection of nitrogen, apply 300,000 times / minute shearing and squeezing force to the pepper powder and vegetable oil for extraction, which lasts for 26 minutes;

[0048] In step 4, the extracted Zanthoxylum bungeanum powder and vegetable oil are subjected to 2-3 phase solid-liquid separation by using a solid-liquid separator to obtain finished Zanthoxylum bungeanum oil and separation slag, wherein the separation slag is used for making carbon rods.

Embodiment 2

[0050] Step 1, take 1kg of dried Zanthoxylum bungeanum, pulverize to the Zanthoxylum bungeanum powder that average particle size is D98=50 μ m;

[0051] Step 2, add the Chinese prickly ash powder and 15kg of vegetable oil preheated to 40°C or 130°C into the vibrating refiner (stick type);

[0052] Step 3, in a fully enclosed environment and under the protection of argon, apply 350,000 times / minute shearing and squeezing force to the pepper powder and vegetable oil for extraction, which lasts for 18 minutes;

[0053] In step 4, the extracted Zanthoxylum bungeanum powder and the vegetable oil are subjected to 2-3 phase solid-liquid separation by using a solid-liquid separator to obtain the finished Zanthoxylum bungeanum oil and the separation slag, wherein the separation slag is used for papermaking.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com