Dyeing technique for polyester cotton or polyester viscose/chinlon/spandex multi-component fabric by one-bath two-step process

A multi-component, two-step technology, applied in dyeing, textiles and papermaking, etc., can solve problems such as poor control of vat difference, long dyeing time, unstable color, etc., to reduce sewage discharge, reduce dyeing time, The effect of shortening the dyeing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: dyeing of polyester / cotton / brocade seamless briefs

[0019] Raw materials: 66.7% 35 / 65 40-count polyester cotton, 2.1% 60-count cotton yarn (for bottom crotch pile), 31.2% 20 / 30-24F nylon core-spun yarn.

[0020] Product: Women's Seamless Briefs

[0021] Color dark brown.

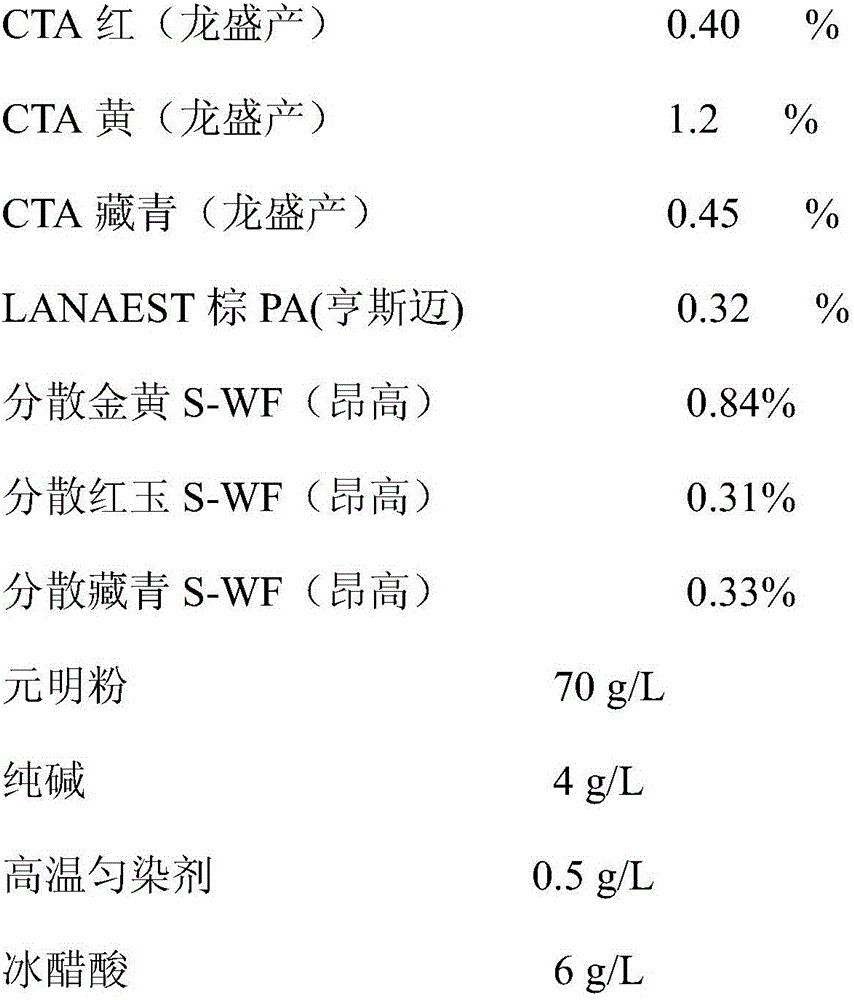

[0022] Dyeing prescription: (Oxygen bleaching before dyeing)

[0023]

[0024]

[0025] Bath ratio: 1:15

[0026] Process operation instructions: Put the product to be dyed into the dyeing vat, enter the specified water volume and heat up to 25°C, add sodium starch powder, high-temperature leveling agent in turn, and continue to run for 5 minutes, then add reactive dyes, neutral dyes and disperse dyes respectively After the dye runs for 5 minutes, raise the temperature to 62°C at 1°C / min, then add soda ash, keep warm for 50 minutes, then neutralize the soda ash with glacial acetic acid, then slowly adjust the pH value to 5.5 with glacial acetic acid, and turn it evenly at 1.5°C...

Embodiment 2

[0031] Example 2: Tencel / polyester seamless sports underwear dyeing

[0032] Raw materials: 69% 50 / 50 Tencel / polyester blended yarn, 31% 20 / 40-36F nylon corespun yarn.

[0033] Products: sports vest, short sleeves

[0034] Color: dark blue.

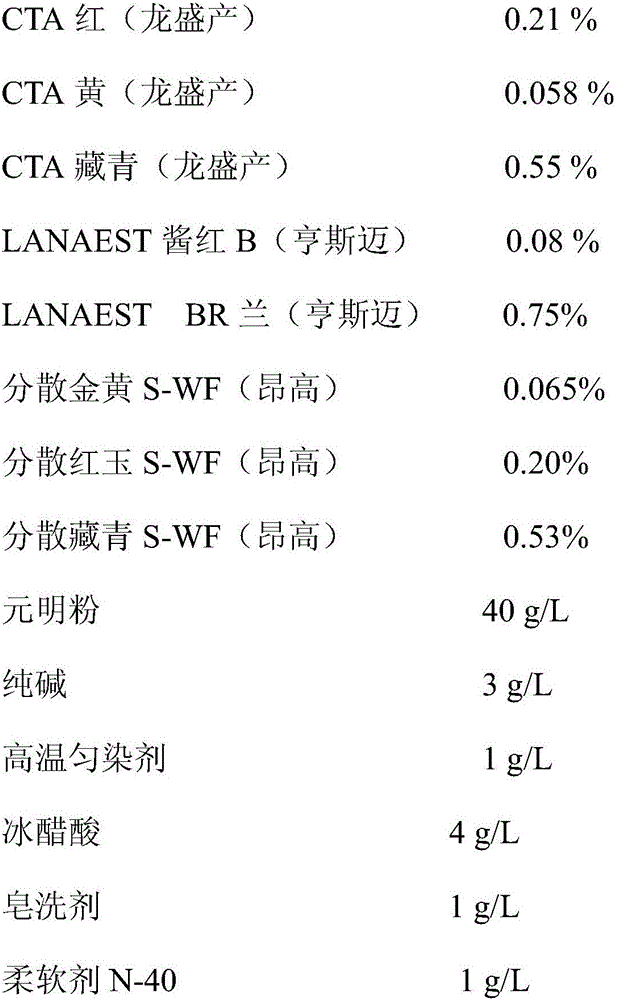

[0035] Dyeing prescription: (refining and degreasing before dyeing)

[0036]

[0037] Bath ratio: 1:15

[0038] Process operation instructions: Put the product to be dyed into the dyeing vat, enter the water to the specified amount and heat up to 30°C, add sodium starch powder, high-temperature leveling agent in turn, and continue to run for 7 minutes, then add reactive dyes, disperse dyes and neutral dyes After running for 7 minutes, raise the temperature to 60°C at 0.7°C / min, then add soda ash and keep it warm for 30 minutes, then neutralize the soda ash with glacial acetic acid, then slowly adjust the pH value to 6.5 with glacial acetic acid, and then turn it evenly and set the temperature at 1°C / min min Raise the temperature to...

Embodiment 3

[0043] Example 3: Momodai / Cotton / Polyester Leggings

[0044] Raw materials: 68% modal / cotton / polyester (modal:cotton:polyester blend ratio 30:30:40), 32% 20 / 40-36F nylon core-spun yarn.

[0045] Product: Seamless Primer

[0046] Color: skin tone.

[0047] Dyeing prescription: (refining oxygen bleaching before dyeing)

[0048]

[0049] Bath ratio: 1:15

[0050] Process operation instructions: Put the product to be dyed into the dyeing vat, enter the specified water volume and heat up to 35°C, add sodium starch powder, high-temperature leveling agent in turn, and continue to run for 10 minutes, then add reactive dyes, disperse dyes, and weak acid dyes After running for 10 minutes, raise the temperature to 58°C at 0.5°C / min, then add soda ash and keep it warm for 40 minutes, then neutralize the soda ash with glacial acetic acid, then slowly adjust the pH value to 6 with glacial acetic acid, and then turn it evenly at 1.2°C / min Min raise the temperature to 128°C and keep it w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com