Preparation and application of In-Sn composite oxide semiconductor ethanol sensor

A composite oxide and semiconductor technology, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of low sensitivity and low detection limit of sensors, and achieve the effects of high sensitivity, low detection limit and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

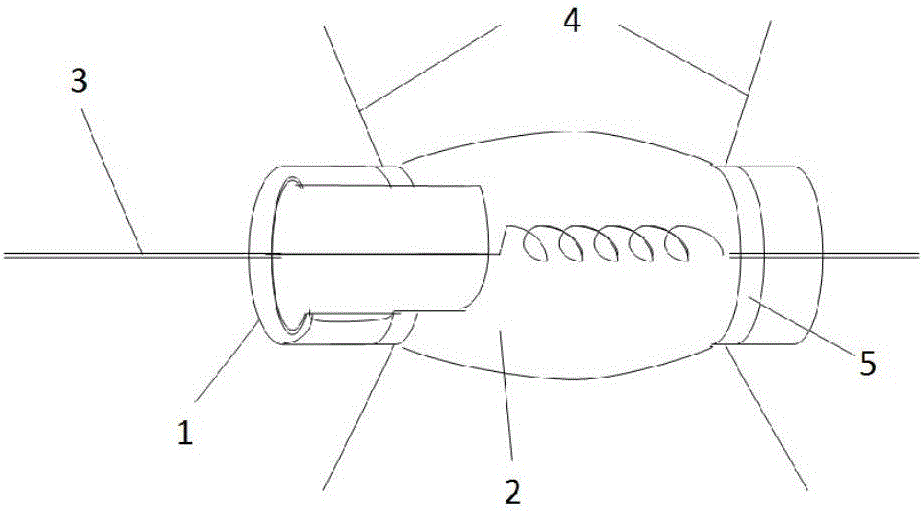

Image

Examples

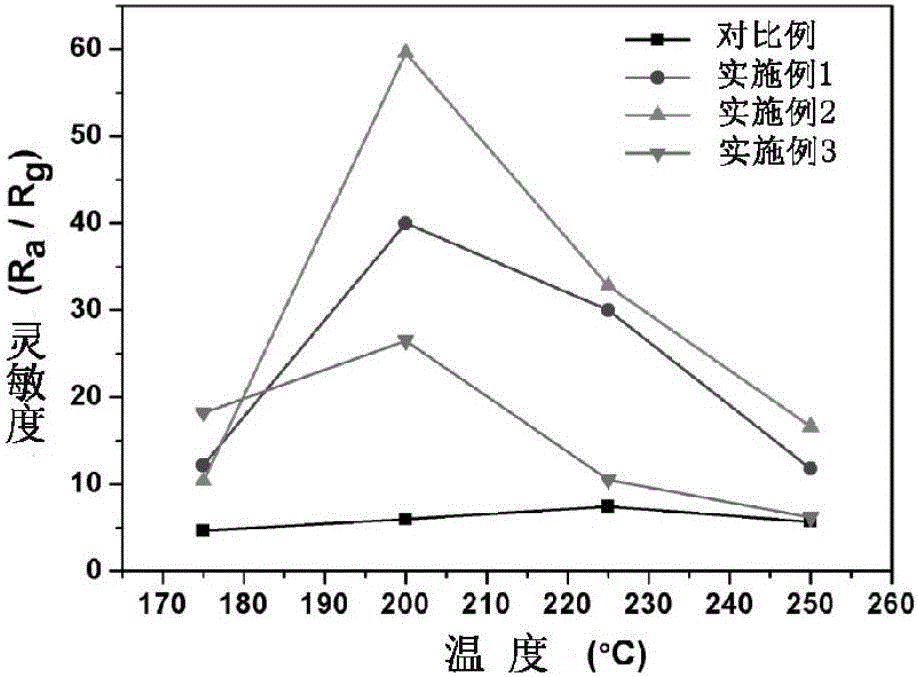

Embodiment 1

[0037] The In-Sn composite oxide semiconductor with a molar ratio of In / Sn in the reactant of 1:2 is used as a sensitive material to make an ethanol sensor. The manufacturing process is as follows:

[0038] (1) First, 0.9g SnCl 2 2H 2 O, 0.586g InCl 3 4H 2 O, 5ml ethylenediamine, 4.41gNa 3 C 6 h 5 o 7 2H 2 0. Dissolve 10ml of NaOH (0.4M) solution in 20ml of water while stirring, and stir for 30 minutes to form a homogeneous solution;

[0039] (2) Put the mixed solution of (1) into a 45ml polytetrafluoroethylene kettle and seal it, put it in an oven at 180°C for 12 hours, cool down to room temperature naturally after the end, collect the samples with ethanol and deionized water and centrifuge them and place them in the culture Keep the dish at 80°C for 12 hours and collect the samples;

[0040] (3) Calcining the above-mentioned nanometer gas-sensitive material at 500°C for 2 hours to obtain a gas-sensitive material, mixing the sensitive material with deionized water in...

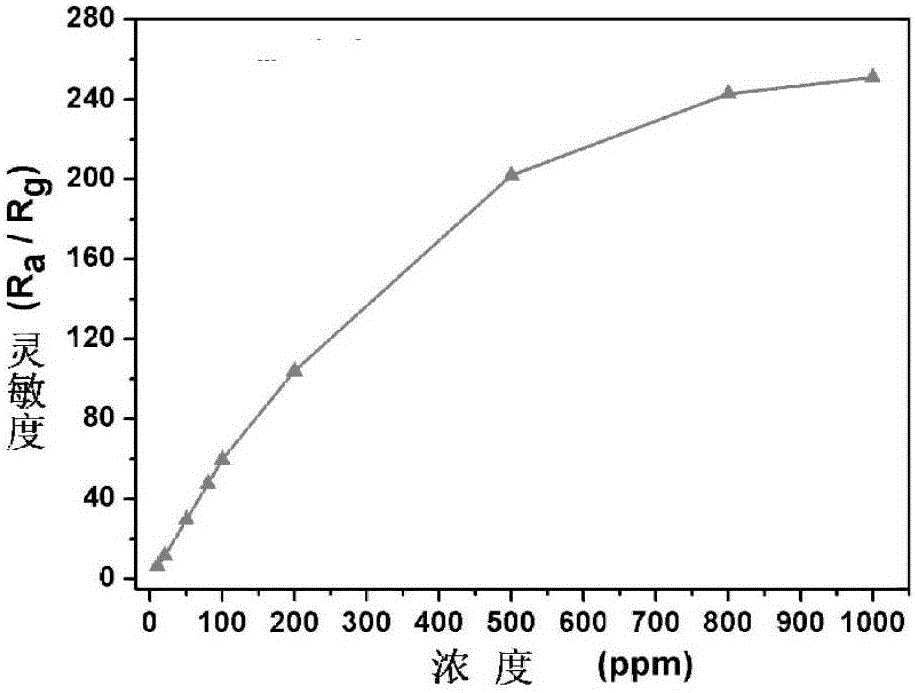

Embodiment 2

[0043] The In-Sn composite oxide semiconductor with a molar ratio of In / Sn in the reactant of 2:2 is used as a sensitive material to make an ethanol sensor. The manufacturing process is as follows:

[0044] (1) First, 0.9g SnCl 2 2H 2 O, 1.173g InCl 3 4H 2 O, 5ml ethylenediamine, 5.88gNa 3 C 6 h 5 o 7 2H 2 0. Dissolve 10ml of NaOH (0.4M) solution in 20ml of water while stirring, and stir for 30 minutes to form a homogeneous solution;

[0045] (2) Put the mixed solution of (1) into a 45ml polytetrafluoroethylene kettle and seal it, put it in an oven at 180°C for 12 hours, cool down to room temperature naturally after the end, collect the samples with ethanol and deionized water and centrifuge them and place them in the culture Keep the dish at 80°C for 12 hours and collect the samples;

[0046] (3) Calcining the above-mentioned nanometer gas-sensitive material at 500°C for 2 hours to obtain a gas-sensitive material, mixing the sensitive material with deionized water in...

Embodiment 3

[0049] The In-Sn composite oxide semiconductor with the In / Sn molar ratio of the element in the reactant is 2:3 is used as the sensitive material to make the ethanol sensor, and the manufacturing process is as follows

[0050] (1) First, 0.9g SnCl 2 2H 2 O, 1.759g InCl 3 4H 2 O, 5ml ethylenediamine, 7.35gNa 3 C 6 h 5 o 7 2H 2 0. Dissolve 10ml of NaOH (0.4M) solution in 20ml of water while stirring, and stir for 30 minutes to form a homogeneous solution;

[0051] (2) Put the mixed solution of (1) into a 45ml polytetrafluoroethylene kettle and seal it, put it in an oven at 180°C for 12 hours, cool down to room temperature naturally after the end, collect the samples with ethanol and deionized water and centrifuge them and place them in the culture Keep the dish at 80°C for 12 hours and collect the samples;

[0052] (3) Calcining the above-mentioned nanometer gas-sensitive material at 500°C for 2 hours to obtain a gas-sensitive material, mixing the sensitive material wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com