Gas chromatograph and detection method for determining total content of sulfides in natural gas

A technology of gas chromatography and detection method, which is applied in the gas chromatograph and detection field for determining the total content of sulfide in natural gas, can solve the problems of cumbersome quantification, low sensitivity, and reduced service life, and achieve accurate test results, wide application range, Test for accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

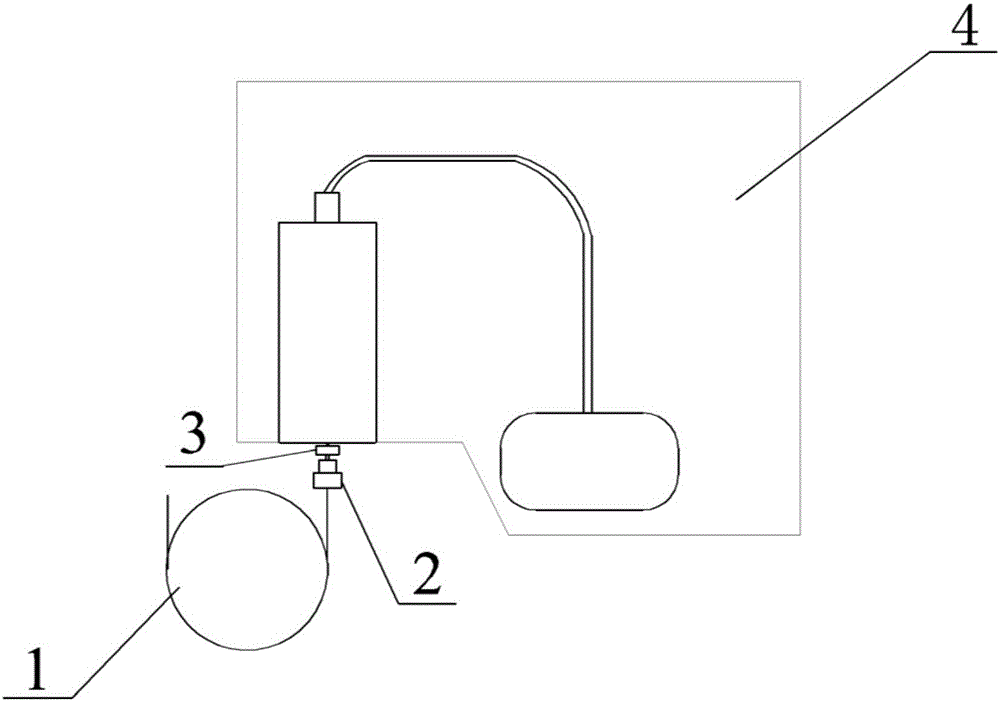

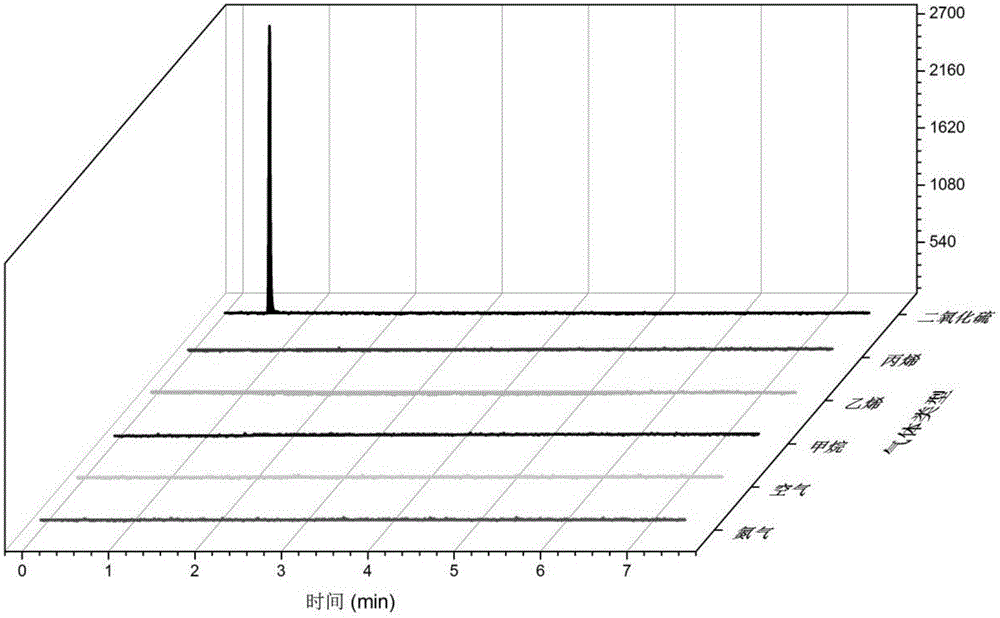

[0028] Test samples containing methane, ethylene, and propylene hydrocarbons separately, and compare them with nitrogen and air samples. The test steps are as follows:

[0029] A. The gas sample of hydrocarbons containing methane enters the hydrogen flame ionization detector 2 from the inlet through the uncoated fused silica capillary column 1 on the inner wall, and fully burns in the hydrogen flame ionization detector 2;

[0030] B. After combustion, the gas enters the sulfur chemiluminescence detector 4 for reaction, the combustion temperature is 800°C, and the air flow rate is 5mL / min;

[0031] C. The processor receives the signal transmitted by the sulfur chemiluminescence detector 4 to obtain a chromatogram;

[0032] D, with single-component sulfur dioxide gas as a standard sample, repeat steps (A) ~ (C);

[0033] E. Integrate the single peak of the chromatogram obtained in step (C) and step (D), and compare the integral values to obtain the total sulfide content in na...

specific Embodiment 2

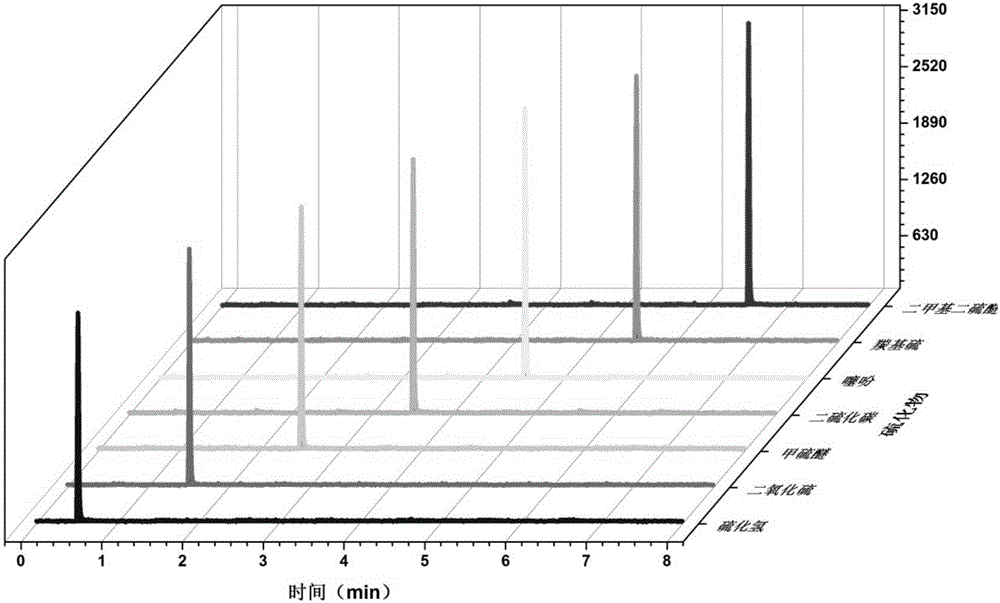

[0036] To test gas samples containing hydrogen sulfide, carbonyl sulfide, sulfur dioxide, methyl mercaptan and methyl sulfide, the specific steps are as follows:

[0037] A. The gas sample containing hydrogen sulfide enters the hydrogen flame ionization detector 2 from the inlet through the uncoated fused silica capillary column 1 on the inner wall, and fully burns in the hydrogen flame ionization detector 2;

[0038] B. After combustion, the gas enters the sulfur chemiluminescence detector 4 for reaction, the combustion temperature is 800°C, and the air flow rate is 5mL / min;

[0039] C. The processor receives the signal transmitted by the sulfur chemiluminescence detector 4 to obtain a chromatogram;

[0040] D, with single-component sulfur dioxide gas as a standard sample, repeat steps (A) ~ (C);

[0041] E. Integrate the single peak of the chromatogram obtained in step (C) and step (D), and compare the integral values to obtain the total sulfide content in natural gas.

...

specific Embodiment 3

[0044] Test the mixture gas containing hydrocarbons such as methane and ethane and multi-component sulfides such as hydrogen sulfide, carbonyl sulfide and methyl mercaptan; the specific steps are as follows:

[0045] A. The mixture gas sample composed of methane, ethane and other hydrocarbons and multi-component sulfides such as hydrogen sulfide, carbonyl sulfide and methyl mercaptan enters the hydrogen flame ion from the inlet through the uncoated fused silica capillary column 1 In the ionization detector 2, fully burn in the hydrogen flame ionization detector 2;

[0046] B. After combustion, the gas enters the sulfur chemiluminescence detector 4 for reaction, the combustion temperature is 800°C, and the air flow rate is 5mL / min;

[0047] C. The processor receives the signal transmitted by the sulfur chemiluminescence detector 4 to obtain a chromatogram;

[0048] D, with single-component sulfur dioxide gas as a standard sample, repeat steps (A) ~ (C);

[0049] E. Integrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com