Production method of walnut milk

A production method, the technology of walnut milk, is applied in the field of food processing, which can solve the problems of not being natural and healthy enough, greasy feeling in the mouth, unstable products, etc., and achieve the effects of easy control, convenient consumption and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

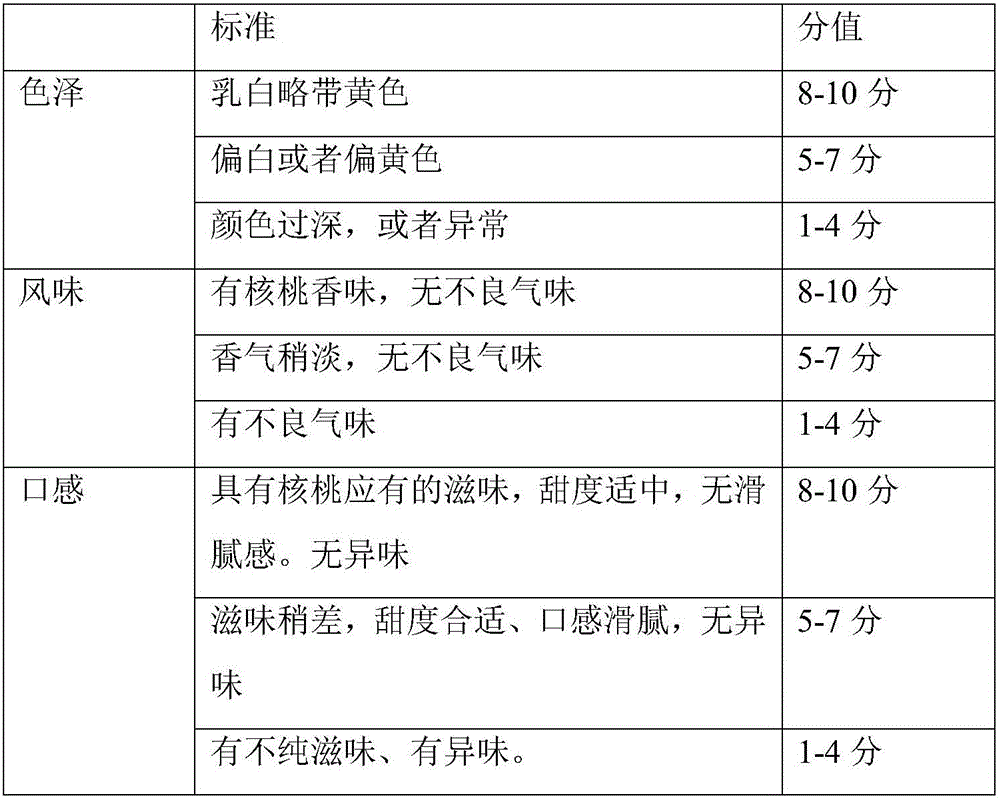

Examples

Embodiment 1

[0031] Embodiment 1: Prepare walnut milk as follows

[0032] (1) Add fresh, plump walnut kernels into 1% lye at a temperature of 70°C, soak for 5 minutes, drain the lye, rinse with a high-pressure water gun, and remove the endocarp.

[0033] (2) Dry the rinsed walnuts at a temperature of 130° C. for 45 minutes. And crush the roasted walnuts.

[0034] (3) Add water to the pulverized walnut kernels to stir and refine. First, add water to the colloidal pulverizer according to the pulverized walnut kernels / water ratio of 1:1. Refining.

[0035] (4) Put the rough refining obtained after stirring in (3) according to the ratio of coarse refining / water 1:1, add water into the colloidal refining, stir and refine at 70°C, and stir and refine for 0.5 hours to obtain walnuts pulp.

[0036] (5) Add sunflower phospholipid (purchased from American East Phosphorus (Dalian) Technology Co., Ltd.) to the walnut pulp obtained after stirring in (4) according to walnut pulp / sunflower phospholip...

Embodiment 2

[0043] Embodiment 2: prepare walnut milk as follows

[0044] (1) adding lye to fresh walnut kernels, washing and removing the inner testa;

[0045] (2) Bake the washed walnuts at a temperature of 135° C. for 40 minutes. The roasted walnuts are crushed;

[0046] (3) adding water to the pulverized walnut kernels according to the mass ratio of raw materials and water of 1:1.5, and performing colloidal grinding; stirring and refining at a temperature of 70° C. and stirring for 0.5 hours to obtain coarse grinding;

[0047] (4) In the rough refining obtained in step (3), add water according to the ratio of the mass ratio of rough refining to water of 1:1.5, and carry out colloidal refining; stirring and refining temperature 40 ° C, stirring time 0.5 hours , to obtain walnut pulp;

[0048] (5) Add sunflower phospholipids to the walnut pulp obtained in step (4) according to the mass ratio of walnut pulp to sunflower phospholipids of 100:0.4, and continue to enter the colloidal grin...

Embodiment 3

[0054] Embodiment 3: prepare walnut milk as follows

[0055] (1) Add fresh, full-grained walnut kernels into 1% lye at 85°C, soak for 5 minutes, drain the lye, rinse with a high-pressure water gun, and remove the endocarp.

[0056] (2) Dry the rinsed walnuts at a temperature of 140° C. for 30 minutes. And crush the roasted walnuts.

[0057] (3) Add water to the crushed walnut kernels and stir and refine. Firstly, add water into the colloid mill for refining according to the raw material / water ratio of 1:2. The stirring and refining temperature is 60°C and the stirring and refining time is 1 hour to obtain coarse refining.

[0058] (4) Put the rough refining obtained after stirring in (3) according to the rough refining / water ratio of 1:2, add water into the colloidal refining, stir and refine at a temperature of 60°C, and stir for 1 hour to obtain walnut pulp .

[0059] (5) Add sunflower phospholipid to the walnut pulp obtained after stirring in (4) according to walnut pulp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com