Automatic drilling machine based on PLC (Programmable Logic Controller) control system

A technology of control system and drilling machine, which is applied in the direction of manufacturing tools, boring/drilling, drilling/drilling equipment, etc. It can solve the problems of easy splashing of iron filings, increased wear of drill bits, and influence of machining accuracy, so as to prevent human operation The effect of fratricide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

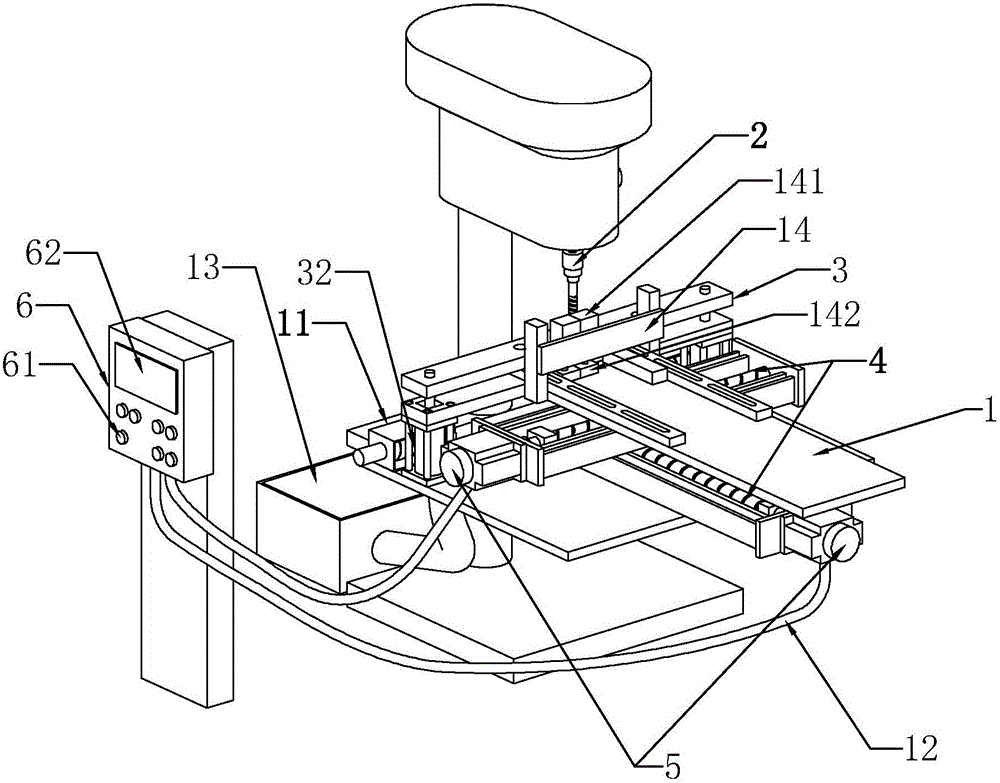

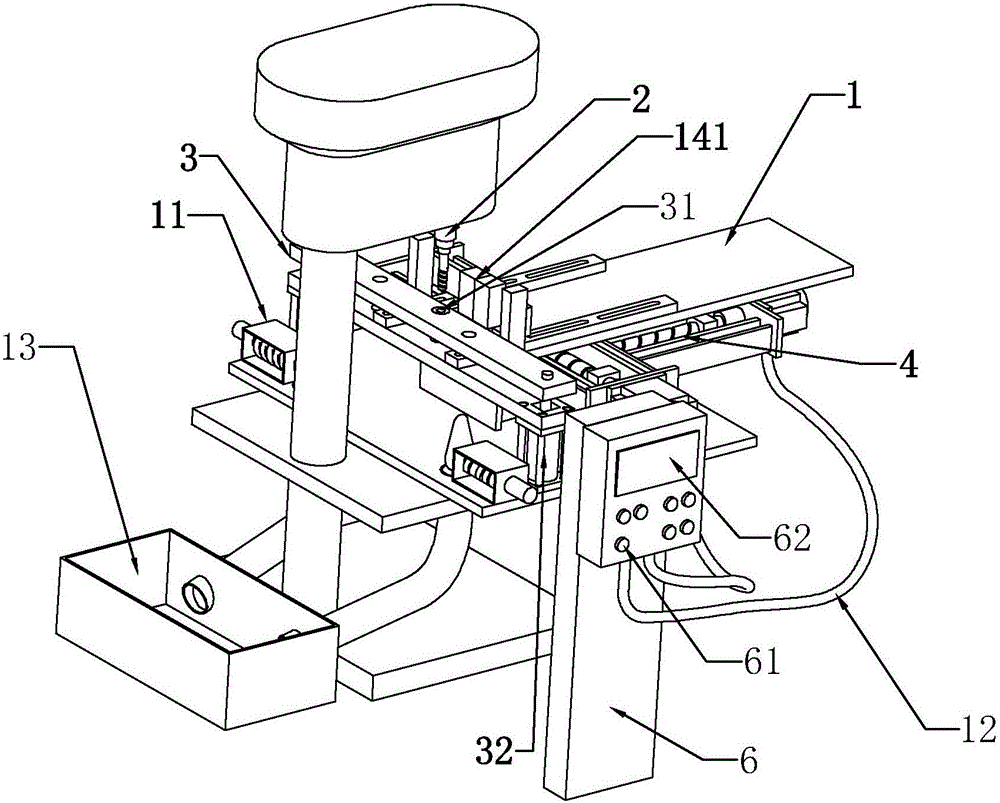

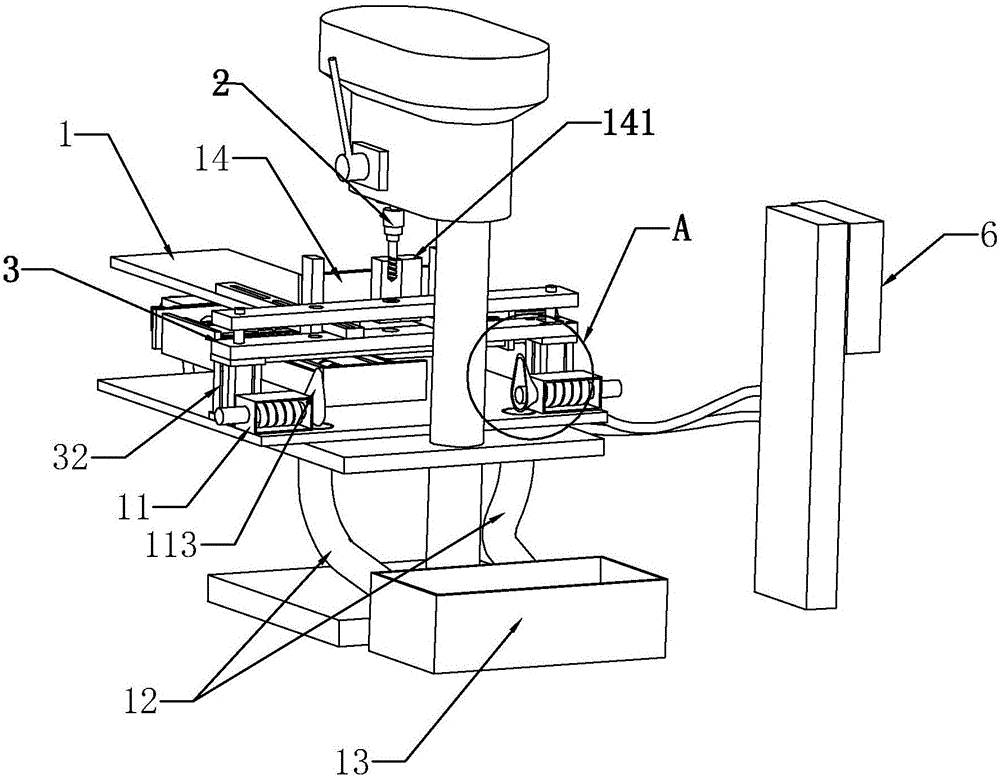

[0020] refer to Figure 1 to Figure 5 The embodiments of the present invention will be further described.

[0021] An automatic drilling machine based on a PLC control system, comprising a workbench 1 and a drill bit 2, the workbench 1 is provided with a vise 3 for clamping; the vise 3 includes two layers up and down, and the upper vise 3 is provided with a drilling hole 31, The drill bit 2 passes through the drill hole 31 during work to realize further processing, and realizes the safety protection of the drill bit 2 during processing. The upper vise 3 is connected with the first cylinder 32 that controls its opening and closing, and is realized by adjusting the distance between the vise 3 on both sides. clamping, the clamping area is larger, and the fixing effect is better; in order to realize the purpose of automatically cleaning iron filings and preventing the drill bit 2 from being stuck in the workpiece, an electromagnetic group 11 is added on the workbench 1, and a guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com