Rapid start method for anaerobic ammonia oxidation reactor

An anaerobic ammonium oxidation, fast-start technology, applied in chemical instruments and methods, anaerobic digestion treatment, water/sludge/sewage treatment, etc. Improve denitrification processing capacity, enhance process stability, and promote growth and retention effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following non-limiting examples can enable those skilled in the art to understand the present invention more fully, but do not limit the present invention in any way.

[0032] 1. Implementation overview

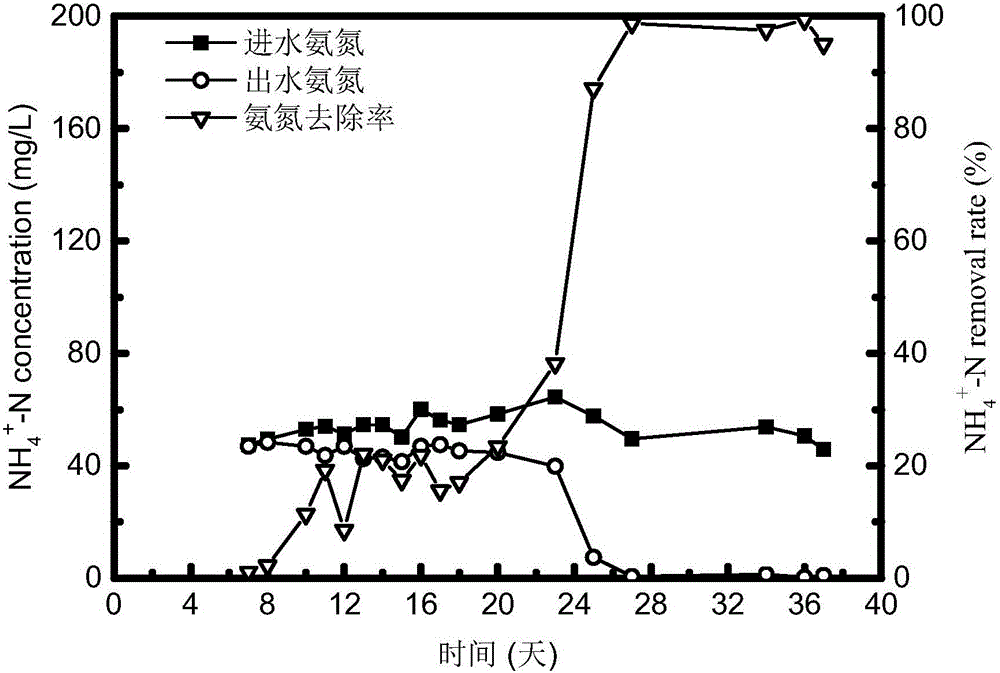

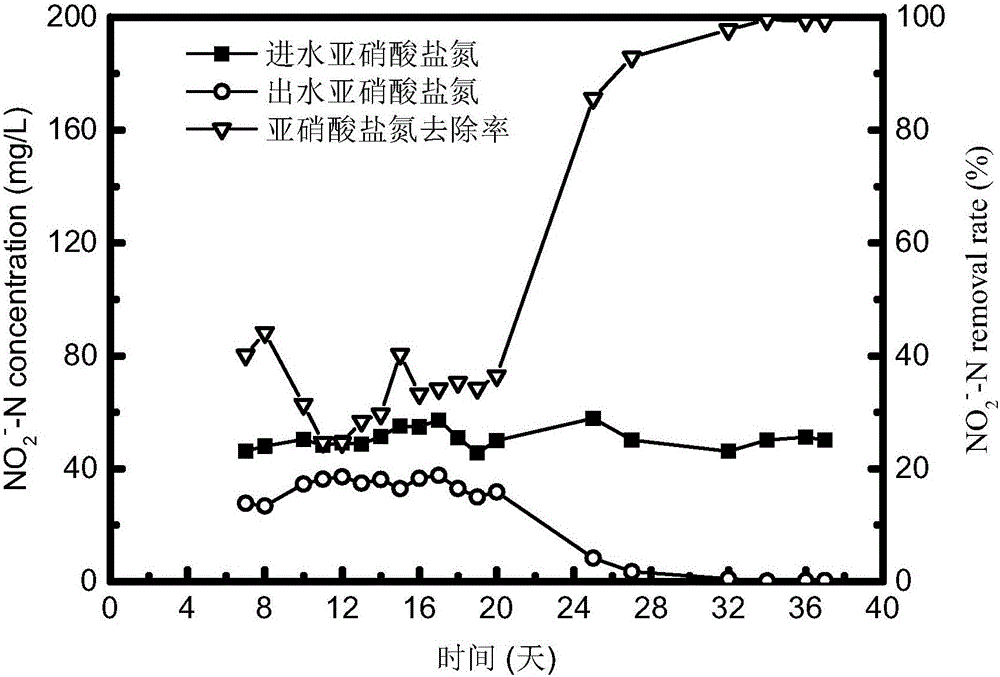

[0033] The dynamic membrane bioreactor is used as the reaction device, and the anaerobic activated sludge is used as the inoculum. It is operated continuously under the condition of anaerobic shading, and nitrogen-containing wastewater is introduced to domesticate and cultivate anammox bacteria to remove ammonia nitrogen in the wastewater. . After 32 days of operation, the quality of the effluent treated by the anammox reactor is as follows: NH 4 + -N≤1.5mg / L, the removal rate is over 95%; NO 2- -N≤1mg / L, the removal rate is above 98%, and the rapid start-up of the anammox reactor has been successfully realized.

[0034] 2. Reactor design

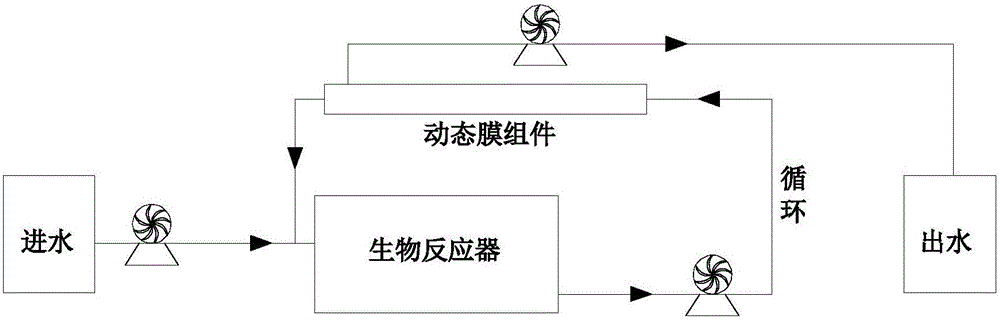

[0035] The anaerobic ammonium oxidation reactor is a combination of an external dynamic membrane and a bioreactor. The dy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com