Production method for dimethyl disulfide

A technology of dimethyl disulfide and production method, which is applied in the direction of hydrogenated polysulfide/polysulfide preparation, organic chemistry, etc., can solve the problems of high industrialization cost, increased cost, and poor control, and achieve reaction safety Smooth, increase production cost, avoid the effect of explosion risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

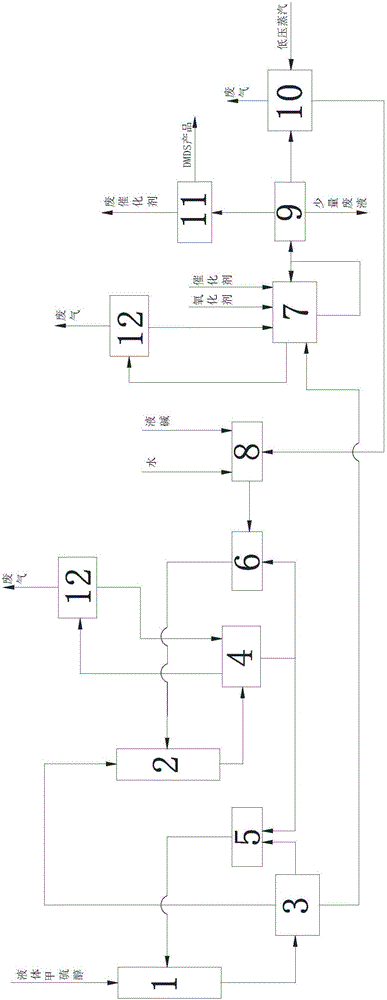

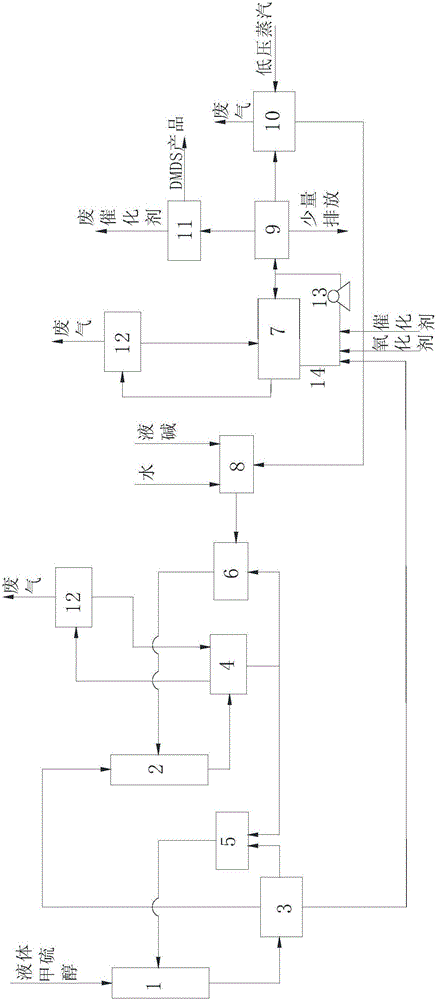

Method used

Image

Examples

Embodiment 1

[0029] A kind of production method of dimethyl disulfide, it specifically carries out according to the following steps:

[0030] (1) Liquid alkali absorption

[0031] Methyl mercaptan is gasified directly through the primary static mixer, and undergoes absorption reaction with excess sodium hydroxide solution, and the unabsorbed methyl mercaptan gas undergoes absorption reaction with excess sodium hydroxide solution again through the secondary static mixer; Wherein, the reaction temperature is 52°C, the mass percentage concentration of the sodium hydroxide solution is 18%, the feed temperature is 52.6°C, and the excess of sodium hydroxide is 3% in terms of molar percentage;

[0032] In the sodium methyl mercaptide product obtained by the reaction of this step, in terms of mass percentage, it contains 20% sodium methyl mercaptide, 3% sodium hydroxide, the balance is water, and trace other impurities, and the formazan it generates The yield of sodium thiolate is as high as 100%...

Embodiment 2

[0037] A kind of production method of dimethyl disulfide, it specifically carries out according to the following steps:

[0038] (1) Liquid alkali absorption

[0039]Methyl mercaptan is gasified directly through the primary static mixer, and undergoes absorption reaction with excess potassium hydroxide solution, and the unabsorbed methyl mercaptan gas undergoes absorption reaction again with excess potassium hydroxide solution through the secondary static mixer; Wherein, the reaction temperature is 55°C, the mass percent concentration of the potassium hydroxide solution is 17.5%, the feed temperature is 55.0°C, and the excess of potassium hydroxide is 5% in terms of molar percentage;

[0040] In the potassium methyl mercaptide product obtained by the reaction of this step, in terms of mass percentage, it contains 23% potassium methyl mercaptide, 3.5% potassium hydroxide, the balance is water, and trace impurities, and the methyl mercaptan it generates The yield of potassium i...

Embodiment 3

[0045] A kind of production method of dimethyl disulfide, it specifically carries out according to the following steps:

[0046] (1) Liquid alkali absorption

[0047] Methyl mercaptan is gasified directly through the primary static mixer, and undergoes absorption reaction with excess potassium hydroxide solution, and the unabsorbed methyl mercaptan gas undergoes absorption reaction again with excess potassium hydroxide solution through the secondary static mixer; Wherein, the reaction temperature is 60°C, the mass percent concentration of the potassium hydroxide solution is 17.0%, the feed temperature is 59.5°C, and the excess of potassium hydroxide is 5.5% in terms of molar percentage;

[0048] In the potassium methyl mercaptide product obtained through the reaction of this step, in terms of mass percentage, it contains potassium methyl mercaptide 19%, potassium hydroxide 2.5%, the remainder is water, and other impurities in trace amounts, and the formazan it generates The y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com