Shoe cellulose powder modified polyurethane adhesive and preparation method thereof

A polyurethane adhesive, powder modification technology, applied in polyurea/polyurethane adhesive, adhesive, adhesive type, etc. Resistance to plasticizer penetration and other problems, to achieve the effect of improving fastness and hydrolysis resistance, good hydrolysis resistance, and improving initial tack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1, preparation of cellulose powder modified polyurethane adhesive for shoes

[0039] (1) 120 mass parts of diphenylmethane diisocyanate, 5 mass parts of hemp stalk core powder (particle size is 20 microns), 60 mass parts of 1,4-butanediol-adipic acid copolymerized binary Add alcohol (molecular weight: 1500) and 330 parts by mass of 1,4-butanediol-1,6-hexanediol-adipic acid copolymerized glycol (molecular weight: 2000) into the reactor, and heat up to 85°C for polymerization 1 hour; then, 30 parts by mass of isophorone diisocyanate was added to the reaction system, and a prepolymerization reaction was carried out at 90° C. for 3 hours to obtain a prepolymer.

[0040] (2) Add 10.5 parts by mass of neopentyl glycol and 20 parts by mass of 1,4 butanediol as a chain extender to the prepolymer obtained in the upper step, and carry out a chain extension reaction at 50°C. After 4 hours of reaction, the reaction The viscosity and temperature of the system are no long...

Embodiment 2

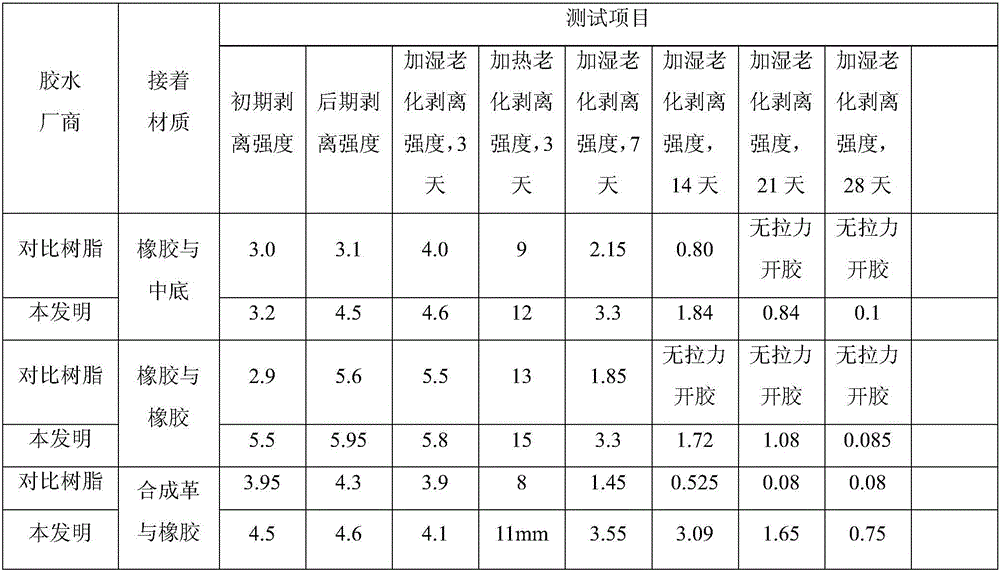

[0042] Embodiment 2, performance test of cellulose powder modified polyurethane adhesive for shoes

[0043] One, the performance test of the cellulose powder modified polyurethane adhesive for shoes prepared in Example 1

[0044] Prepare the composite shoe sole with the modified polyurethane adhesive prepared in Example 1: use the modified polyurethane adhesive to bond the rubber outsole and the midsole. Among them, the composite shoe sole is made of short fiber (addition amount not less than 3%) modified rubber (natural rubber, butadiene rubber content is not less than 55%) outsole, hemp stalk core ultrafine powder (addition amount is not less than 3%) Modified EVA foaming injection molded midsole and thermoplastic polyurethane injection molded foot arch support frame are made by bonding hemp stalk core superfine powder modified polyurethane glue.

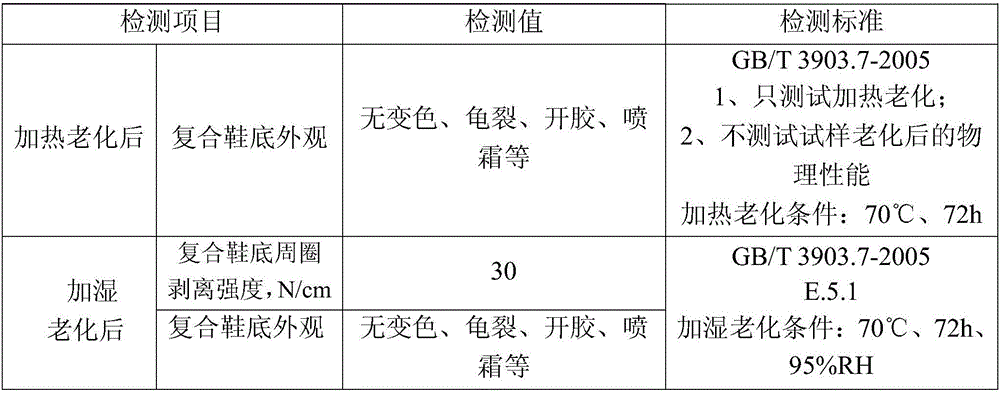

[0045] The performance test results of the composite shoe sole prepared above are shown in Table 1.

[0046] Table 1 Performan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com