Method for producing small peptides through bionic enzymatic hydrolysis

A bionic enzymolysis and enzymolysis technology, applied in the biological field, can solve the problems of affecting the properties of small peptide products, large loss of product peptides, incomplete purification, etc., and achieve the effects of increasing use value, reducing losses, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

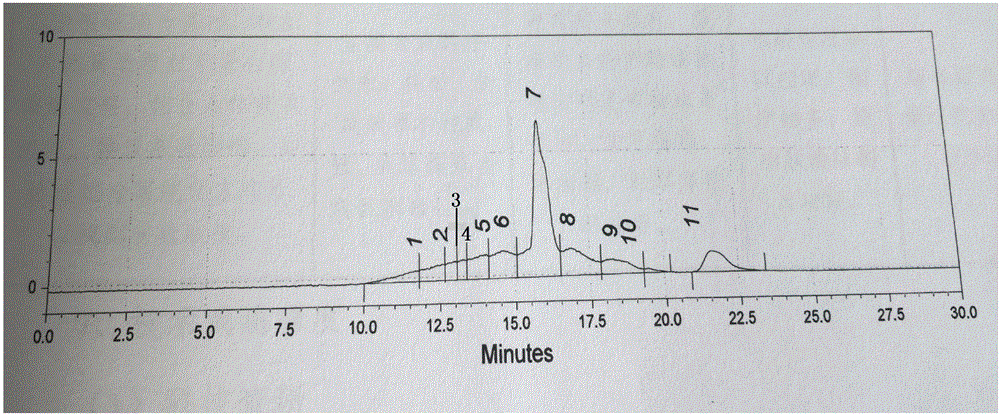

Image

Examples

Embodiment 1

[0030] A method for producing small peptides by biomimetic enzymolysis, comprising the following steps:

[0031] (1) Grind ground beetle insects, pass through a 80-mesh sieve, add 10 times the weight of water to homogenate, add dilute hydrochloric acid, adjust the pH to 1.5-2, add pepsin with 1% raw material mass, and enzymolyze at 40°C for 1 hour ; Then, add sodium hydroxide solution to adjust the pH to 7.5-8, add trypsin with 1% raw material mass, and enzymolyze at 40° C. for 3 hours to obtain an enzymatic hydrolysis solution;

[0032] (2) Centrifuge the enzymatic solution at 4000-4500r / min for 10-15min, and take the supernatant. , take the supernatant, perform ultrafiltration with a hollow fiber membrane with a molecular weight cut-off of 3KD, and collect the permeate; after testing, the total peptide amount before filtration is 19.24g; after filtration, the total peptide amount is 19.02g, and the loss peptide amount is 1.1 %, almost no loss of total peptide amount.

[00...

Embodiment 2

[0040] A method for producing small peptides by biomimetic enzymolysis, comprising the following steps:

[0041] (1) Grinding donkey-hide gelatin, passing through a 80-mesh sieve, adding 15 times the weight of water to homogenate, adding dilute hydrochloric acid, adjusting the pH to 1.5-2, adding pepsin with a mass of 1.2% of the raw material, and enzymatically hydrolyzing at 37°C for 1.5h ; Then, add sodium hydroxide solution to adjust the pH to 7.5-8, add trypsin with 1% raw material mass, and enzymolyze at 37° C. for 4 hours to obtain an enzymatic hydrolysis solution;

[0042] (2) Centrifuge the enzymatic solution at 4000-4500r / min for 10-15min, and take the supernatant. , take the supernatant, perform ultrafiltration with a hollow fiber membrane with a molecular weight cut-off of 3KD, and collect the permeate; after testing, the total peptide amount before filtration is 19.24g; after filtration, the total peptide amount is 19.02g, and the loss peptide amount is 1.1 %, alm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com